Methods Of Vendor Evaluation

About methods of vendor evaluation

Where to Source Methods of Vendor Evaluation Services?

The global market for vendor evaluation services is increasingly concentrated among specialized compliance and quality assurance providers in Asia, particularly within China and Vietnam. These regions host a growing number of third-party assessment firms offering standardized and customizable supplier vetting protocols. Industrial hubs such as Shanghai, Qingdao, and Ho Chi Minh City have developed robust ecosystems integrating audit logistics, documentation verification, and digital reporting platforms, enabling rapid deployment of on-site and remote evaluations.

Suppliers in these clusters benefit from proximity to high-density manufacturing zones, allowing same-week scheduling for factory audits across multiple provinces. This geographic advantage reduces lead times for vendor qualification by up to 40% compared to Western-based consultancies. Additionally, localized labor costs contribute to competitive pricing structures—basic evaluation packages start at $0.49 per unit with minimum orders as low as 10 units—making scalable assessments economically viable for SMEs and large enterprises alike.

How to Evaluate Methods of Vendor Evaluation Providers?

Selecting an effective vendor assessment partner requires rigorous due diligence focused on operational transparency, methodological rigor, and service scope. Buyers should prioritize the following criteria:

Methodological Standards

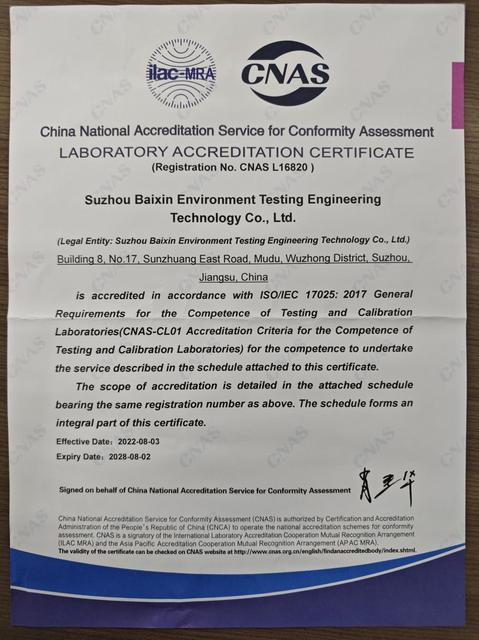

Confirm that the provider implements internationally recognized frameworks such as ISO 19011 (guidelines for management system auditing) or ANSI/ASQ Z1.4 (inspection standards). Leading suppliers offer structured processes including pre-audit documentation reviews, real-time production floor inspections, and post-assessment corrective action tracking. Cross-reference service descriptions with actual deliverables such as detailed audit reports, photographic evidence, and compliance scoring matrices.

Service Capability Verification

Assess technical capacity through key indicators:

- Minimum team size of 5 certified auditors with sector-specific expertise (e.g., electronics, textiles, machinery)

- Provision of multi-language reporting (English, Spanish, German preferred for global buyers)

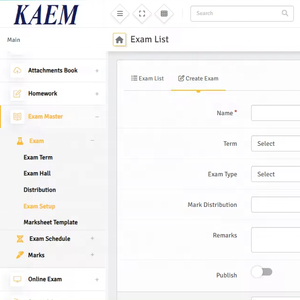

- Digital access to real-time audit data via secure portals or API integration

Correlate response time metrics (target ≤8 hours) with on-time delivery performance to gauge reliability under tight timelines.

Risk Mitigation Protocols

Require contractual guarantees for audit accuracy and impartiality. Validate use of GPS-stamped photo logs and time-coded video walkthroughs to prevent report falsification. For high-value sourcing programs, insist on dual-auditor teams and unannounced inspection options. Review historical reorder rates—suppliers with repeat client engagement above 30% typically demonstrate consistent service quality.

What Are the Top Methods of Vendor Evaluation Service Providers?

| Company Name | Location | Service Focus | Audit Types Offered | On-Time Delivery | Avg. Response | Customization Options | Reorder Rate | Price Range (Min. Order) |

|---|---|---|---|---|---|---|---|---|

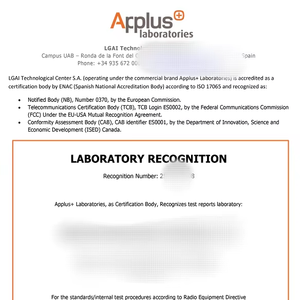

| Applus China Co., Ltd. | China | Electrical & laboratory accreditation, supplier compliance | Accreditation, product inspection, third-party verification | 100% | ≤8h | - | - | $1–5 (1 unit) |

| MEKONG DELTA IMPORT EXPORT COMPANY LIMITED | Vietnam | Garment sourcing, factory audits, apparel compliance | Production monitoring, social compliance, shipment inspection | - | ≤23h | Material, design, packaging | - | $0.10–5 (1k–1M pieces) |

| Market Union Co., Ltd. | China | Supplier search, initial qualification, due diligence | Supplier discovery, capability screening, risk profiling | 100% | ≤5h | Color, material, logo, packaging | - | $0.49–1.99 (10 bags) |

| INTER Q & A SERVICES, UNIPESSOAL LDA | China (Portugal-managed) | Factory evaluation, plant audits, compliance certification | Full manufacturing assessment, pre-shipment checks, system audits | - | ≤3h | - | - | $250–800 (1 unit) |

| Qingdao I-Flow Co., Ltd. | China | Industrial component supply with embedded supplier validation | Technical drawing review, material testing, pressure certification | 100% | ≤7h | Pdf, drawing, flange, monogram | 30% | $12–350 (5–10 pieces) |

Performance Analysis

Applus China and Market Union stand out for punctuality, both achieving 100% on-time delivery with sub-8-hour response times, making them suitable for time-sensitive procurement cycles. INTER Q & A SERVICES commands premium pricing ($250–800 per audit) but offers comprehensive manufacturing evaluations aligned with international quality systems. MEKONG DELTA specializes in apparel and textile supply chains, providing end-to-end sourcing support beyond basic audits. Qingdao I-Flow integrates vendor evaluation into component supply workflows, offering technical customization and verifiable performance data—ideal for buyers requiring engineering-level validation.

FAQs

How are vendor evaluation reports verified for authenticity?

Top-tier providers use geotagged photography, timestamped video footage, and digitally signed PDF reports to ensure traceability. Independent clients can request direct communication with auditors or verify credentials through issuing bodies like IRCA or CQI.

What is the typical turnaround time for a factory audit?

Standard evaluations are completed within 3–5 business days post-inspection, including report generation and client review. Expedited services (24–48 hour delivery) are available from providers with in-region auditor networks, subject to additional fees.

Can vendor evaluation services be customized for specific industries?

Yes, leading suppliers tailor checklists to industry standards—such as AQL for textiles, IATF 16949 for automotive, or ISO 13485 for medical devices. Customization includes process-specific KPIs, regulatory benchmarks, and risk-weighted scoring models.

Do providers offer ongoing supplier monitoring?

Some suppliers, particularly those serving long-term sourcing partners, offer subscription-based monitoring programs with quarterly audits, non-conformance tracking, and improvement roadmaps. These are especially valuable for managing tier-2 and tier-3 suppliers in complex supply chains.

What factors influence the cost of vendor evaluation?

Costs vary based on scope (desktop vs. on-site), depth (compliance-only vs. full operational review), location (domestic vs. cross-border), and frequency. Remote assessments start below $1/unit, while comprehensive on-site audits in high-cost regions may exceed $1,000 per visit.