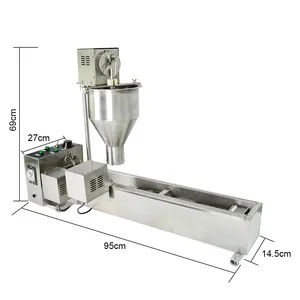

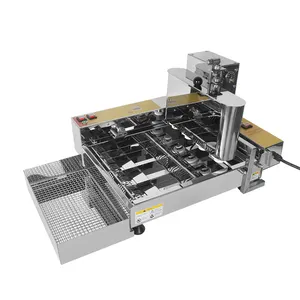

Mini Automatic Donut Maker

About mini automatic donut maker

Where to Find Mini Automatic Donut Maker Suppliers?

China remains the central hub for commercial mini automatic donut maker manufacturing, with Guangzhou emerging as a key production cluster in Guangdong Province. This region hosts vertically integrated supply chains specializing in foodservice equipment, enabling streamlined fabrication of electromechanical components, heating systems, and stainless steel molds. The concentration of engineering talent and precision machining workshops supports rapid prototyping and scalable production runs.

Suppliers in this ecosystem typically operate facilities exceeding 2,000m², integrating R&D, sheet metal processing, assembly, and quality testing under one roof. Proximity to ports like Nansha and Shekou facilitates efficient export logistics, with standard lead times ranging from 15–30 days for containerized orders. Buyers benefit from localized sourcing of core materials—primarily SUS304 stainless steel and aluminum alloy molds—reducing material costs by 18–25% compared to offshore alternatives. Monthly production capacity across major suppliers ranges from 300 to 1,200 units, accommodating both small-batch trials and bulk procurement.

How to Choose Mini Automatic Donut Maker Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

Verify adherence to international electrical and food safety standards, including CE, CB, or ETL certifications where applicable. Confirm use of food-grade stainless steel (SUS304) for contact surfaces and robust thermal control systems capable of maintaining 160–190°C operating temperatures. Request test reports for insulation resistance, grounding continuity, and temperature stability under continuous load.

Production & Customization Capability

Assess infrastructure through documented evidence:

- Minimum factory area of 2,000m² with dedicated assembly lines

- In-house mold design and CNC fabrication capabilities

- Capacity for OEM/ODM customization (voltage: 110V/220V; output: 600–1,200 pcs/h; tray configuration)

- Ability to apply custom branding, color finishes, and packaging layouts

Cross-reference declared on-time delivery rates (target ≥95%) with order history data to validate reliability.

Procurement Safeguards

Utilize secure payment mechanisms such as letter of credit or platform-based escrow services. Prioritize suppliers offering sample validation before mass production. Conduct pre-shipment inspections to verify build quality, automation performance, and compliance with agreed specifications. Analyze reorder rates as an indicator of customer satisfaction—suppliers exceeding 30% demonstrate consistent product reliability.

What Are the Best Mini Automatic Donut Maker Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Goodloog Kitchen Equipment Co., Ltd. | Guangzhou, CN | Other Snack Machines (532), Waffle Makers (255) | US $40,000+ | 100% | ≤2h | 15% | 1–2 sets | $590–$1,440 |

| Guangzhou Tailang Industrial Co., Ltd. | Guangzhou, CN | Customization-focused, multiple configurations | US $990,000+ | 93% | ≤3h | <15% | 1–5 units | $58.29–$499 |

| Guangzhou Goodloog Catering Equipment Co., Ltd. | Guangzhou, CN | Waffle Makers (275), Other Snack Machines (241) | US $170,000+ | 100% | ≤2h | 38% | 1–2 sets | $670–$1,450 |

| Guangzhou Chashimi Kitchen Equipment Co., Ltd. | Guangzhou, CN | Customization options available | US $160,000+ | 95% | ≤5h | <15% | 1–10 sets | $499–$730 |

| Jiangmen Kolice Refrigeration Equipment Co., Ltd. | Jiangmen, CN | Ice Cream Machine (244), Donut Machine (37) | US $150,000+ | 97% | ≤8h | 16% | 1 unit | $800–$1,134 |

Performance Analysis

Guangzhou Goodloog Catering Equipment stands out with a 38% reorder rate—the highest in the segment—indicating strong customer retention and product consistency. Despite higher entry pricing, its 100% on-time delivery and responsive communication support reliable fulfillment. Guangzhou Tailang offers the broadest price flexibility, with models starting below $60 per unit, making it suitable for low-cost entry into new markets. Jiangmen Kolice targets premium commercial clients with high-voltage, fully automated systems priced above $800, backed by robust technical infrastructure. Buyers seeking customization should prioritize suppliers listing design adaptability in their tags, particularly those offering voltage, capacity, and aesthetic modifications. For cost-sensitive buyers, MOQs as low as one set reduce initial investment risk, while larger orders (5–10 sets) unlock volume discounts.

FAQs

What is the typical minimum order quantity (MOQ) for mini automatic donut makers?

MOQs range from 1 piece/set to 10 sets depending on model and supplier. Entry-level models often require only one unit, while customized or lower-priced units may require 5–10 sets to qualify for discounted rates.

What are common lead times after order confirmation?

Standard production lead time is 15–25 days. Custom configurations may extend this to 30–35 days. Add 7–14 days for air freight or 25–40 days for sea shipping based on destination.

Can suppliers customize voltage and plug types?

Yes, most suppliers offer dual-voltage options (110V/220V) and can configure plugs for North American, European, or Australian standards. Confirmation must be provided during technical specification review.

Do manufacturers provide samples for quality testing?

Sample availability varies. Some suppliers offer paid samples (typically 1.5x unit price) with refund upon full order placement. Free samples are rare but possible for high-volume commitments (e.g., 20+ units).

What materials are used in construction?

Primary materials include SUS304 stainless steel for frying chambers and structural frames, aluminum alloy for molds, and heat-resistant plastics for control panels. Seals and gaskets are typically silicone-based for thermal durability.