Mini Mechanical Lathe Distributor

CN

CN

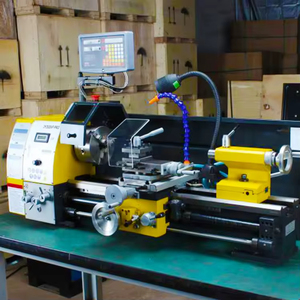

About mini mechanical lathe distributor

Where to Find Mini Mechanical Lathe Distributors?

China remains the central hub for mini mechanical lathe manufacturing, with key production clusters in Shanghai, Yangzhou, and Anhui provinces driving competitive advantages through vertically integrated supply chains. These regions host specialized machinery factories that combine precision engineering with cost-efficient production models, enabling global distribution at scalable volumes. Suppliers benefit from proximity to raw material sources, CNC component manufacturers, and export logistics networks—particularly in Shanghai and Qingdao—which reduce lead times and transportation costs.

The industrial ecosystem supports both standard and customized lathe configurations, ranging from hobby-grade bench models to industrial-duty turning machines. Facilities typically operate under lean manufacturing principles, with average factory areas exceeding 2,000m² and monthly outputs adjusted to order demand. Buyers access a mature network where design, machining, assembly, and quality testing occur within consolidated facilities, ensuring consistency across batches. This localization enables typical lead times of 15–30 days for standard units and 30–45 days for custom builds, with production cost savings of 20–35% compared to Western-based manufacturers.

How to Choose Mini Mechanical Lathe Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional criteria:

Technical Compliance & Quality Assurance

Verify adherence to international quality standards such as ISO 9001, although formal certification is not universally declared among listed suppliers. For end-use applications requiring regulatory compliance (e.g., CE-marked equipment for EU markets), request documentation on material traceability, spindle accuracy testing, and safety guarding. Assess product specifications for critical parameters including swing over bed, spindle bore diameter, motor power (ranging from 300W to 500W in entry-level models), and taper accuracy (e.g., MT2–MT3 tooling compatibility).

Production Capability Assessment

Prioritize suppliers demonstrating in-house machining capabilities and consistent output capacity. Key indicators include:

- Factory size exceeding 1,000m² for stable volume production

- In-house CNC processing, gear cutting, and surface grinding units

- Dedicated R&D or technical support teams for customization requests

Cross-reference online revenue data and reorder rates: suppliers with US $1M+ annual digital sales (e.g., Wmt Cnc Industrial Co., Ltd.) often maintain higher inventory turnover and process maturity.

Customization and After-Sales Support

Confirm scope of modification options—including color, labeling, packaging, voltage configuration (110V/220V), and accessory bundling (chucks, tool posts, steady rests). Evaluate responsiveness via recorded metrics; top-tier suppliers respond to inquiries within ≤3 hours and maintain 100% on-time delivery records. Request facility videos or photos to validate claimed production lines before committing to large orders.

Transaction Security & Sampling

Utilize secure payment mechanisms such as escrow services to mitigate risk. Require sample testing prior to bulk procurement—evaluate runout accuracy, vibration levels at high RPM, and gearbox noise. Average sampling lead time ranges from 7–14 days, with air freight delivery adding 5–10 days internationally. MOQs vary from 1 set for retail buyers to 20 sets for discounted wholesale pricing.

What Are the Best Mini Mechanical Lathe Suppliers?

| Company Name | Location | Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Wmt Cnc Industrial Co., Ltd. | China | Custom Manufacturer | US $3.1M+ | 100.0% | ≤4h | <15% | Mini hobby lathes, CNC variants, industrial models | Spindle bore, phase, color, machine stand, work light |

| Shanghai Sumore Industrial Co., Ltd. | Shanghai, CN | Multispecialty Supplier | US $120K+ | 100.0% | ≤3h | 25% | Bench lathes, metal turning machines | Color, material, size, logo, packaging |

| Anhui Citie Technology Co., Ltd. | Anhui, CN | Custom Manufacturer | US $470K+ | 97% | ≤2h | <15% | CT-series manual lathes, horizontal models | Model, color, size, logo, packaging |

| Shanghai Sihao Machinery Equipment Co., Ltd. | Shanghai, CN | Manufacturer | US $1.7M+ | 98% | ≤6h | <15% | Entry-level mini lathes, wood/metal models | Limited customization reported |

| Yangzhou Enyun Precision Machinery Factory | Yangzhou, CN | Machinery Factory | US $10K+ | 100.0% | ≤3h | <15% | Manual lathes, small metal turning machines | Not specified |

Performance Analysis

Wmt Cnc Industrial leads in scale and customization breadth, supported by high digital transaction volume and comprehensive technical configurability. Shanghai Sumore stands out with a 25% reorder rate—indicating strong customer retention—and rapid response times, suggesting efficient post-sale service. Anhui Citie offers competitive pricing (as low as $590/unit) with near-perfect delivery performance and fast communication. While some suppliers like Yangzhou Enyun report lower online revenue, their 100% on-time delivery record indicates reliability for smaller-volume buyers. Custom manufacturers generally provide greater flexibility for OEM branding and technical modifications compared to multispecialty distributors.

FAQs

How to verify mini mechanical lathe supplier reliability?

Validate claims through documented evidence: request business licenses, third-party audit reports, and test certificates for critical components. Analyze transaction history, focusing on consistent on-time delivery (>97%) and response efficiency (≤4h). Review product listings for detailed technical drawings and tolerance specifications.

What is the typical MOQ and pricing range?

MOQs start at 1 set for most suppliers, with bulk discounts available at 20+ units. Prices range from $275 for basic hobby lathes to $8,680 for CNC-integrated models. Industrial-grade manual lathes typically fall between $1,300–$2,650 per unit.

Can suppliers customize lathes for specific markets?

Yes, leading manufacturers offer voltage adaptation (110V/220V), language-specific manuals, CE-compliant guards, and branded packaging. Some support full OEM services including logo engraving, custom paint, and tailored accessory kits.

Do mini lathe suppliers support global shipping?

All listed suppliers export internationally. Confirm FOB terms and coordinate with freight forwarders for sea or air shipment. Sea freight is optimal for container loads, while express air shipping suits samples and urgent single-unit deliveries.

Are samples available before mass production?

Most suppliers provide paid samples, typically priced at 1.5x–2x unit cost, which may be credited toward future orders. Sample production takes 7–14 days, with global delivery in 5–10 days via express carriers.