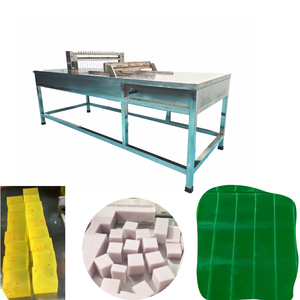

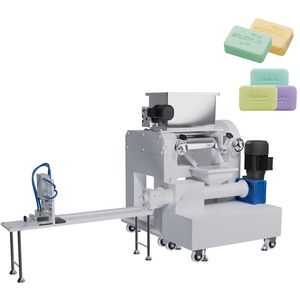

Mini Soap Making Machine

About mini soap making machine

Where to Find Mini Soap Making Machine Suppliers?

China remains the global epicenter for mini soap making machine manufacturing, with key production clusters in Henan and Guangdong provinces. These regions host vertically integrated supply chains that support rapid prototyping, cost-efficient component sourcing, and scalable assembly lines. Henan specializes in compact industrial machinery, leveraging established logistics networks through Zhengzhou for efficient export operations. Guangdong’s Pearl River Delta hub offers proximity to precision engineering workshops and packaging suppliers, reducing lead times by up to 25% compared to non-specialized regions.

The concentration of specialized manufacturers enables buyers to access turnkey solutions—from cold-process extruders to fully automatic stamping lines—within a single ecosystem. Facilities typically integrate CNC machining, hydraulic system calibration, and mold fabrication on-site, allowing customization without compromising delivery timelines. Average production capacity among leading suppliers ranges from 50–200 units per month, supporting both pilot batches and volume orders. Buyers benefit from localized material sourcing (primarily stainless steel 304/316 and aluminum alloys), which maintains consistent quality while minimizing raw material cost volatility.

How to Choose Mini Soap Making Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Verify adherence to international standards such as CE or ISO 9001 where applicable. While not all suppliers hold formal certifications, prioritize those providing test reports for motor efficiency, pressure tolerance, and cycle durability. For automated models, confirm programmable logic controller (PLC) integration and user interface stability under continuous operation.

Production Capability Verification

Assess infrastructure maturity using the following benchmarks:

- Minimum factory area exceeding 1,000m² for dedicated production zones

- In-house engineering teams capable of customizing mold designs, feed systems, or automation levels

- Proven track record in exporting, indicated by multi-language documentation and compliance with regional electrical specifications (e.g., 220V/50Hz vs. 110V/60Hz)

- On-time delivery rate above 95%, validated through platform-verified performance metrics

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services to mitigate risk during initial transactions. Request product videos or real-time facility walkthroughs to validate claims about automation level and build quality. Pre-shipment inspections should include functional testing of compression force, demolding consistency, and safety interlocks. Confirm packaging suitability for sea freight, particularly moisture resistance and shock absorption for control panels.

What Are the Best Mini Soap Making Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Henan Lovo Industry Co., Ltd. | Henan, CN | Multiple machinery types | US $540,000+ | 95% | ≤3h | 23% | Color, material, size, logo, packaging, label, graphic |

| Nomi Electronic Technology LLC | Guangdong, CN | Oil Pressers, Waste Treatment Machinery | Data not available | Data not available | ≤2h | Data not available | Not specified |

| Guangzhou Zhigong Intelligent Equipment Co., Ltd. | Guangdong, CN | Soap Making Machines (306), Chemical Equipment | US $6,000+ | 100% | ≤4h | 16% | Not specified |

| Zhengzhou Kovi Machinery Co., Ltd. | Henan, CN | Soap Making Machines, Chemical Equipment | US $200,000+ | 100% | ≤4h | 15% | Color, material, size, logo, packaging, label, graphic |

| Wellink Machinery Inc | Shandong, CN | Other Chemical Equipment (20,859+ listings) | Data not available | Data not available | ≤2h | Data not available | Not specified |

Performance Analysis

Suppliers based in Henan demonstrate higher reorder rates and verified delivery performance, with Henan Lovo Industry achieving a 23% reorder rate and sub-3-hour response time. Zhengzhou Kovi Machinery and Guangzhou Zhigong stand out for specialization, each maintaining over 300 active listings specifically in soap-making equipment, indicating focused expertise. Wellink Machinery and Nomi Electronic Technology exhibit fast response behaviors but lack transparency in delivery history and revenue, suggesting potential risks for first-time buyers. Customization capability is explicitly offered by two suppliers—Henan Lovo and Zhengzhou Kovi—enabling tailored branding, dimensional adjustments, and material substitutions for niche market requirements.

FAQs

What is the typical price range for mini soap making machines?

Prices vary significantly based on automation level and output capacity. Manual and semi-automatic models start at $840 per set, while fully automatic compact lines range from $4,000 to $8,800. High-output industrial variants exceed $8,700. Most suppliers quote FOB terms with a standard MOQ of 1 set, enabling low-risk trial procurement.

What are common production techniques supported by these machines?

Suppliers offer equipment for cold pressing, pneumatic molding, hydraulic compression, and continuous extrusion processes. Cold-process machines preserve sensitive additives like essential oils, while hot-process compatible units include integrated heating elements and temperature controls. Stamping models achieve higher throughput (up to 1,000 bars/hour), whereas manual presses suit artisanal or small-batch producers.

How long do production and shipping take?

Manufacturing lead time averages 15–30 days after order confirmation, depending on customization complexity. Air freight delivers within 5–10 days but is cost-prohibitive for heavy machinery. Sea freight remains optimal for full-container loads, with transit times of 20–40 days to major global ports. Express courier options (DHL, FedEx) are viable only for disassembled components.

Can suppliers provide machine validation samples?

Sample policies differ: some suppliers offer functional demonstrations via video or live stream instead of physical units due to weight and logistics constraints. When available, sample sets may incur partial charges (30–50% of unit cost), often credited toward bulk orders. Buyers should request stamped soap outputs to evaluate mold clarity and ejection efficiency.

What customization options are commonly available?

Key customizable parameters include mold cavity design (logo engraving, shape geometry), frame color, voltage configuration, and control panel language. Advanced suppliers support OEM labeling, packaging integration, and modular upgrades such as conveyor attachments or automatic feeding systems. Design modifications require CAD file submission or physical templates for mold reproduction.