Mirror Frames

Top sponsor listing

Top sponsor listing

1/3

1/3

1/2

1/2

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/21

1/21

0

0

1/7

1/7

1/3

1/3

About mirror frames

Where to Find Mirror Frames Suppliers?

China remains a central hub for mirror frame manufacturing, with key production clusters in Guangdong, Shandong, and Hebei provinces. These regions host vertically integrated supply chains combining metal fabrication, woodworking, glass processing, and decorative finishing under one ecosystem. Foshan in Guangdong specializes in aluminum and alloy-based frames, leveraging proximity to raw material suppliers and export ports. Shandong’s industrial base emphasizes large-format decorative and floor-mounted mirror systems, while Hebei producers focus on cost-efficient acrylic and wood-composite solutions for mass-market distribution.

The concentration of component manufacturers—such as extrusion plants, CNC workshops, and surface treatment facilities—within 50km radii enables rapid prototyping and scalable production. This integration reduces lead times by 20–30% compared to fragmented sourcing models. Buyers benefit from localized logistics, access to diverse materials (including anti-fog coatings, LED integration, and bone inlay finishes), and the ability to fulfill both high-volume orders and bespoke designs. Average production lead times range from 15 to 35 days, depending on customization complexity and material availability.

How to Choose Mirror Frames Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Production & Customization Capability

Assess whether suppliers support required design parameters: material type (wood, MDF, aluminum, acrylic, iron), finish options (antique, vintage, modern, art deco), dimensional flexibility, and branding integration (logo embossing, custom packaging). Prioritize manufacturers offering end-to-end customization—from shape and color to anti-fog functionality and smart features—with documented process control.

Quality Assurance Metrics

Verify consistent performance indicators:

- On-time delivery rate ≥97%

- Average response time ≤2 hours

- Reorder rate below 20% indicating stable customer satisfaction

- Evidence of standardized quality checks for warping, adhesion, coating durability, and structural integrity

While formal certifications (e.g., ISO 9001) are not universally listed, consistent on-time delivery and low reorder rates serve as proxy indicators of internal quality management systems.

Transaction Reliability & Risk Mitigation

Utilize secure payment mechanisms such as escrow services where funds are released upon shipment verification. Evaluate online revenue history (where available) as an indicator of market acceptance. Request physical or digital samples to validate material claims, especially for handcrafted elements like bone inlay or rotating mechanisms. Confirm packaging standards to prevent breakage during transit, particularly for large or framed units.

What Are the Best Mirror Frames Suppliers?

| Company Name | Main Materials | Customization Options | Min. Order Quantity | Price Range (USD) | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Chaozhou Wonder Industry Co., Ltd. | Wood, MDF, Metal, Composite | Color, shape, size, logo, packaging, design, anti-fog, graphic frame | Varies by product | $8–$49+ | 100% | ≤1h | $270,000+ | <15% |

| Shandong Longwei Economic And Trading Co., Ltd. | Metal, Wood, Acrylic, Flannel | Color, material, size, design, logo, packaging, graphic frame | 20–50 pieces | $5.69–$49 | 100% | ≤1h | $250,000+ | <15% |

| Shijiazhuang Jumei Red Glass Products Co., Ltd. | Acrylic, Iron, Wood, Glass | Limited customization per listing | 1–50 pieces | $2.49–$43.20 | 100% | ≤1h | $3,000+ | <15% |

| APEX ALIGN | Bone Inlay, Wood Composite | Handmade geometric, scalloped, luxury art deco styles | 2 pieces | $15.99–$19.99 | 100% | ≤1h | $1,000+ | Not reported |

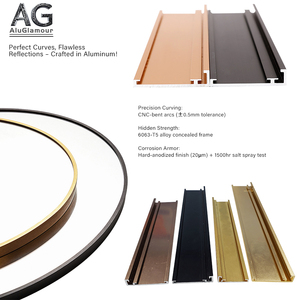

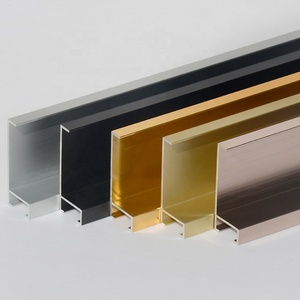

| Foshan Hailv Metal Products Co., Ltd. | Aluminum Alloy, Metal Profiles | Custom profiles, contemporary designs, smart mirrors | 6–120 meters | $0.55–$2.30/meter | 100% | ≤1h | $10,000+ | 16% |

Performance Analysis

Top-tier suppliers demonstrate full-cycle customization, sub-hour response times, and flawless on-time delivery records. Chaozhou Wonder and Shandong Longwei lead in versatility, supporting broad material and design adaptations with high transaction volumes ($250K+ online revenue), indicating strong market demand and fulfillment reliability. APEX ALIGN specializes in niche, handcrafted bone inlay frames with very low MOQs (2 pieces), ideal for boutique retailers or sample testing. Foshan Hailv offers profile-based aluminum framing at competitive per-meter pricing, suited for commercial projects requiring architectural integration. Shijiazhuang Jumei provides entry-level pricing with flexible single-piece ordering but limited customization transparency. All top performers maintain 100% on-time delivery and rapid responsiveness, reducing procurement risk.

FAQs

How to verify mirror frame supplier reliability?

Cross-check delivery performance, response time, and order history where available. Request product specifications, material data sheets, and finish durability tests. Conduct virtual factory audits to observe production lines and quality checkpoints. Prioritize suppliers with documented customization workflows and packaging protocols.

What is the typical MOQ for mirror frames?

MOQ varies by material and format: aluminum profiles often require 6–120 meters; assembled decorative frames range from 1 to 50 pieces; handcrafted designs may accept as few as 2 units. High-volume standard items typically start at 20–30 pieces.

Are customization options widely available?

Yes, most leading suppliers offer extensive customization including size, shape, color, finish, branding (logo, labels), packaging, and functional features like anti-fog coatings or LED lighting. Confirm design submission formats (CAD, sketches) and tooling lead times before approval.

What are common materials used in mirror frames?

Primary materials include aluminum alloy (lightweight, corrosion-resistant), solid wood/MDF (decorative, premium finishes), iron (structural strength), acrylic (impact-resistant, budget-friendly), and composite materials like bone inlay for artisanal appeal.

How long does production and shipping take?

Production lead time averages 15–35 days post-approval. Air freight delivers samples in 7–10 days; sea freight for bulk orders takes 25–40 days depending on destination. Expedited production may reduce timelines by 30% with surcharge.