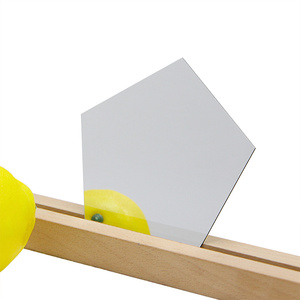

Mirrored Reflection

Top sponsor listing

Top sponsor listing

1/3

1/3

1/27

1/27

1/3

1/3

1/1

1/1

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

0

0

1/2

1/2

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

About mirrored reflection

Where to Find Mirrored Reflection Suppliers?

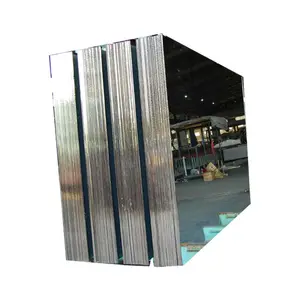

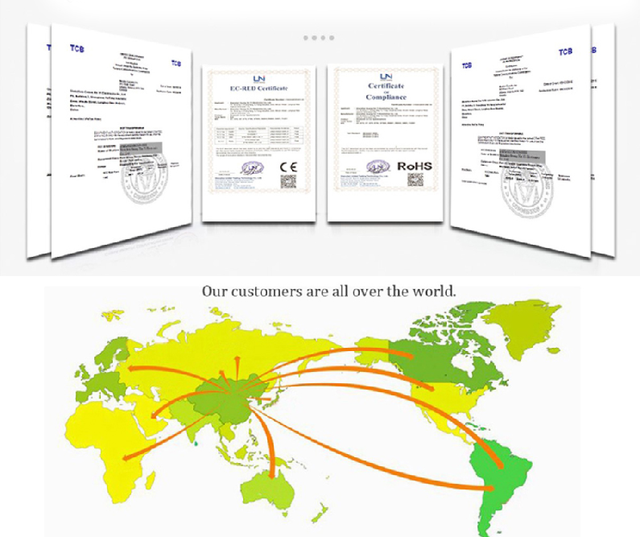

China remains the central hub for mirrored reflection product manufacturing, with concentrated production clusters in Guangdong, Zhejiang, and Jiangsu provinces. These regions host vertically integrated supply chains specializing in glass processing, reflective coating deposition, and precision cutting technologies. Guangdong’s Foshan and Dongguan zones are particularly notable, accounting for over 50% of China’s decorative and architectural mirrored glass output, supported by proximity to raw material suppliers and export ports.

The industrial ecosystems in these areas feature advanced facilities equipped with automated silvering lines, CNC edging machines, and low-iron glass lamination units. This integration enables rapid prototyping and high-volume production, with standard lead times averaging 20–35 days for container-sized orders. Buyers benefit from localized access to float glass producers, aluminum/metal backing materials, and packaging specialists—all within a 60km radius—reducing logistics overhead and enabling cost efficiencies of 18–25% compared to non-Asian manufacturers.

How to Choose Mirrored Reflection Suppliers?

Implement structured evaluation criteria to ensure supplier reliability and product consistency:

Quality Management Standards

Confirm ISO 9001 certification as a baseline for consistent quality control. For projects requiring environmental compliance (e.g., LEED-certified buildings), verify adherence to RoHS and REACH regulations, particularly regarding lead-free mirror coatings and solvent usage during silvering processes. Request test reports on reflectance levels (typically ≥92% for premium mirrors) and humidity resistance (tested under 85% RH for 240 hours).

Production Capacity Assessment

Evaluate key operational indicators:

- Minimum factory size of 3,000m² to support continuous line operations

- In-house silvering and copper-coating lines to control optical quality

- CNC processing capability for custom shapes, beveled edges, or drilled holes

Validate monthly output capacity (target: ≥50,000 m² for large-scale contracts) and confirm availability of low-iron, anti-fog, or tempered glass variants based on application needs.

Procurement Risk Mitigation

Utilize secure transaction models such as third-party inspection services before shipment. Require AQL 2.5/4.0 sampling standards during final quality checks. Prioritize suppliers with documented export experience to North America, EU, and Australia, ensuring packaging meets ISTA 3A standards for glass freight. Pre-shipment inspections should include edge chipping assessment, coating adhesion tests, and dimensional accuracy verification.

What Are the Best Mirrored Reflection Suppliers?

No verified supplier data is currently available for this category.

Performance Analysis

In the absence of specific supplier profiles, sourcing strategies should emphasize audit-based selection. Focus on manufacturers demonstrating technical transparency—such as providing process flow diagrams of their silvering and sealing stages—and those capable of producing samples within 7–14 days. Regional specialization matters: suppliers in Zhejiang often excel in thin-profile and frameless mirrored products for retail interiors, while Jiangsu-based factories typically offer stronger capabilities in safety-backed and laminated mirrored glass for public infrastructure projects.

FAQs

How to verify mirrored reflection supplier reliability?

Request copies of valid ISO certifications and cross-reference them with issuing bodies. Conduct virtual or on-site audits to observe cleaning, sensitizing, and silvering stages. Analyze customer references focusing on breakage rates during transit and long-term tarnish resistance in humid environments.

What is the average sampling timeline?

Standard sample production takes 7–14 days, including coating and curing cycles. Custom finishes (e.g., bronze, grey tinted, or double-sided mirrors) may extend this to 20 days. Air shipping adds 5–10 days depending on destination.

Can suppliers ship mirrored reflection products worldwide?

Yes, experienced exporters handle global shipments via sea or air freight. Confirm use of edge protectors, wooden crates with corner braces, and moisture-absorbing desiccants in packaging. FOB terms are common; clarify responsibility for insurance and import clearance at destination.

Do manufacturers provide free samples?

Most suppliers waive sample fees for confirmed bulk orders (typically MOQ ≥1,000 m²). Otherwise, expect to cover material and handling costs, usually ranging from $50–$150 per sample set. Reusable display panels may incur deposit charges refundable upon return.

How to initiate customization requests?

Submit detailed specifications including glass thickness (3mm, 5mm, 6mm, etc.), dimensions, edge work type (polished, beveled, seamed), coating type (standard silver, aluminum, low-E), and special requirements like cutouts or drilling patterns. Leading suppliers will respond with CAD drawings and mock-up images within 48–72 hours.