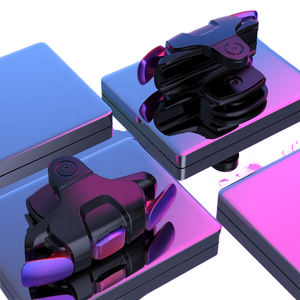

Mobile Game Controller For Android Producer

1/3

1/3

1/16

1/16

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/39

1/39

1/1

1/1

1/3

1/3

1/3

1/3

1/2

1/2

1/2

1/2

0

0

1/3

1/3

1/25

1/25

About mobile game controller for android producer

Where to Find Mobile Game Controller for Android Producers?

China remains the central hub for consumer electronics manufacturing, with mobile game controller production concentrated in Guangdong and Jiangsu provinces. These regions host integrated supply chains for printed circuit boards (PCBs), microcontrollers, lithium polymer batteries, and injection-molded ABS/PC housing materials. Shenzhen, within Guangdong, operates as a high-velocity electronics ecosystem where component sourcing, SMT assembly, and firmware integration occur within tightly coordinated industrial zones.

The clustering enables rapid prototyping and scalable production, with many facilities supporting monthly outputs exceeding 100,000 units. Vertical integration reduces material lead times by 25–40% compared to decentralized manufacturing models. Buyers benefit from proximity to testing labs, logistics hubs, and certification bodies, streamlining compliance with international safety and electromagnetic compatibility standards. Typical advantages include MOQs as low as 500–1,000 units for standard designs and 3,000+ for customized models, with average production lead times ranging from 25 to 35 days post-sample approval.

How to Choose Mobile Game Controller for Android Producers?

Implement structured evaluation criteria to ensure technical reliability and operational scalability:

Quality Management Compliance

Confirm ISO 9001 certification for standardized quality control processes. For markets requiring regulatory adherence, verify RoHS, CE, FCC, and BQB certifications—particularly critical for Bluetooth 5.0+ modules and battery safety. Request test reports from accredited labs covering ESD protection, signal stability, and cycle life (minimum 10,000 actuations for triggers and joysticks).

Production Capability Assessment

Evaluate core infrastructure metrics:

- Minimum 2,000m² factory area with dedicated SMT and final assembly lines

- In-house mold-making and plastic injection capabilities for housing customization

- Embedded software development team for firmware updates and button mapping functionality

Validate throughput capacity: leading producers maintain surface-mount technology (SMT) lines capable of placing 40,000+ components per hour with automated optical inspection (AOI) systems ensuring defect rates below 200 PPM.

Procurement Risk Mitigation

Utilize secure transaction mechanisms such as third-party escrow or letter of credit for initial orders. Prioritize suppliers with documented export experience to North America, Europe, or Southeast Asia, confirming packaging compliance with drop-test and vibration standards. Conduct pre-shipment inspections via independent auditors to verify functionality, cosmetic quality, and labeling accuracy (including user manuals and regulatory markings).

What Are the Best Mobile Game Controller for Android Producers?

No verified supplier data is currently available for this product category. Buyers should initiate sourcing through direct manufacturer engagement on business-to-business platforms or industry exhibitions such as the China International Consumer Electronics Show (CICES) or Hong Kong Electronics Fair. Emphasis should be placed on verifying physical facility ownership, production line automation levels, and historical order fulfillment performance before procurement commitment.

Performance Analysis

In absence of published performance data, due diligence must focus on validating self-reported capabilities. Cross-reference claims of monthly output, R&D staffing, and certification status with third-party verification services. High-performing producers typically allocate 8–12% of workforce to engineering roles focused on human-machine interface (HMI) optimization, latency reduction (<30ms), and multi-device compatibility (Android OS 8.0+, OTG support). Prioritize partners offering SDK access for custom profile integration and providing detailed failure mode analysis (FMA) reports upon request.

FAQs

How to verify mobile game controller producer reliability?

Request factory audit reports from recognized inspection agencies. Verify business license authenticity through official Chinese government portals. Assess responsiveness, technical depth in replies, and willingness to provide real-time production footage. Review customer references, particularly those in target export markets.

What is the average sampling timeline?

Standard sample production takes 7–14 days, including PCB assembly, firmware loading, and basic functional testing. Custom molds for ergonomic housings extend timelines to 20–25 days. Air shipping adds 5–8 days for international delivery. Expect full compliance testing cycles to require an additional 10–15 days if not pre-certified.

Can manufacturers ship globally?

Yes, experienced producers manage FOB, CIF, and DDP shipments worldwide. Confirm UN38.3 certification for lithium-containing controllers and proper MSDS documentation. Sea freight is cost-effective for container loads; air express suits small batches under 2 CBM.

Do producers offer free samples?

Sample fees are typically charged but may be waived for confirmed bulk orders (e.g., ≥5,000 units). Standard sample costs range from $80–$150, covering material and labor. Mold development for custom designs incurs non-recurring engineering (NRE) fees between $2,000–$6,000, often partially refundable against future orders.

How to initiate customization requests?

Submit detailed specifications including dimensions, button layout (e.g., ABXY, D-pad, gyro support), connectivity protocol (Bluetooth HID, USB-C), battery capacity (mAh), and desired certifications. Reputable manufacturers respond with 3D CAD models within 72 hours and deliver functional prototypes within four weeks for validation.