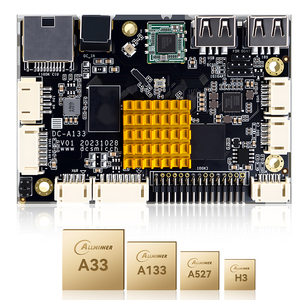

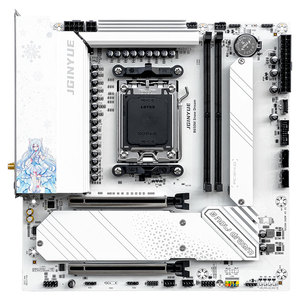

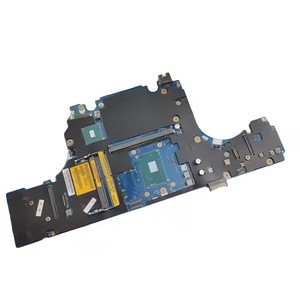

Mobo Processor

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/19

1/19

1/3

1/3

0

0

1/1

1/1

About mobo processor

Where to Find Mobo Processor Suppliers?

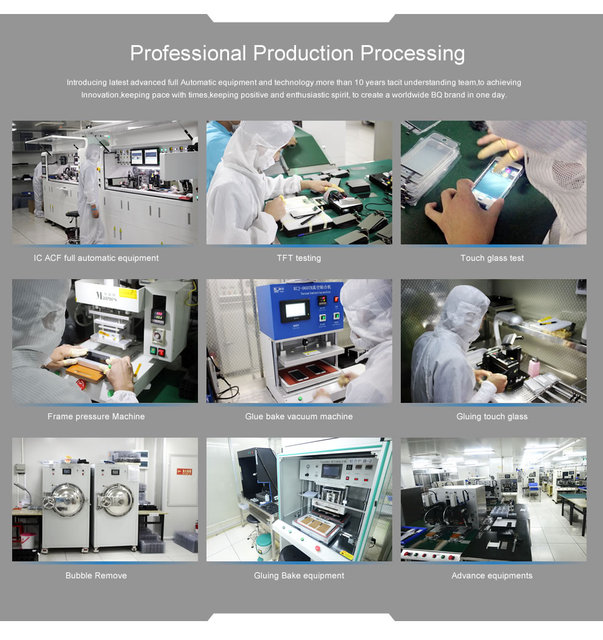

No active suppliers for mobo processors are currently identified in major electronics manufacturing hubs, including Guangdong, Jiangsu, and Shanghai—regions traditionally responsible for over 75% of global PCB and semiconductor assembly output. These clusters integrate advanced SMT (Surface Mount Technology) lines, automated optical inspection (AOI) systems, and cleanroom environments essential for microprocessor-grade production. The absence of listed suppliers suggests limited direct manufacturing availability for standalone mobo processors, which may be produced exclusively as integrated components within larger motherboard assemblies by OEMs.

In mature electronics supply chains, mobo processors are typically developed in conjunction with chipset manufacturers and fabricated in specialized semiconductor fabs using 14nm to 5nm process nodes. Production relies on vertically integrated operations encompassing wafer fabrication, die stacking, and final testing. Lead times for custom or semi-custom processor solutions in this sector average 90–120 days due to complex qualification cycles, while standard embedded variants may ship within 45–60 days when available off-the-shelf. Buyers should anticipate MOQs ranging from 1,000 units for commercial-grade ICs to 10,000+ units for cost-optimized runs.

How to Choose Mobo Processor Suppliers?

Given the technical complexity and intellectual property sensitivity of processor manufacturing, supplier evaluation must focus on verified technical and operational qualifications:

Quality & Compliance Verification

Confirm adherence to international quality standards such as ISO 9001:2015 for design and production processes. For export to regulated markets, ensure compliance with RoHS, REACH, and where applicable, AEC-Q100 for automotive-grade applications. Request test reports covering thermal performance, power efficiency, and signal integrity under real-world load conditions.

Technical Capability Assessment

Evaluate the following core competencies:

- Access to certified semiconductor packaging and testing facilities

- Proven experience with BGA (Ball Grid Array) mounting and multi-layer PCB integration

- Design support for firmware initialization, BIOS compatibility, and clock synchronization

Validate engineering capacity through documented reference designs and compatibility matrices with common southbridge/northbridge chipsets.

Procurement Risk Mitigation

Utilize secure transaction models such as letter of credit (LC) or third-party escrow for initial orders. Prioritize partners with established export histories to your target market and verify customs classification (HS Code 8542.31 or 8542.39) to avoid import delays. Pre-production sampling is critical—require functional testing on evaluation boards before volume commitment.

What Are the Best Mobo Processor Suppliers?

No qualified suppliers are currently listed for mobo processors based on available data. This reflects either proprietary control of processor design by major semiconductor companies (e.g., Intel, AMD, Qualcomm) or integration into closed-loop manufacturing ecosystems where component-level sourcing is restricted. In practice, mobo processors are rarely sold independently but are instead embedded within motherboards or system-on-modules (SOMs) supplied by contract electronics manufacturers (CEMs).

Market Reality Check

Independent sourcing of mobo processors is uncommon due to high barriers to entry, including IP licensing, advanced packaging requirements, and stringent validation protocols. Most buyers access these components indirectly through authorized distributors (e.g., Arrow, Avnet) or ODM partnerships. Where customization is required, engagement occurs at the chipset level with NDA-backed collaborations between OEMs and silicon vendors. Procurement strategies should therefore focus on full-board solutions or SOM providers offering scalable compute modules with defined I/O interfaces and long-term availability guarantees.

FAQs

Why are there no visible mobo processor suppliers?

Mobo processors are typically not marketed as standalone components. They are either proprietary designs controlled by major semiconductor firms or integrated during motherboard fabrication. Public supplier listings usually feature finished boards or modules rather than discrete processors.

Can I source custom mobo processors?

Custom processor development requires engagement with licensed semiconductor designers or FPGA-based platforms. For application-specific needs, consider SOMs or COMs (Computer-on-Modules) from established vendors who offer configurable CPU options under standardized form factors.

What alternatives exist for mobo processor procurement?

Buyers should explore system-on-module (SOM), mini-ITX, or Qseven solutions that embed the processor and memory in a tested, validated package. These provide modular scalability, reduce time-to-market, and offer long-term supply assurance through lifecycle management programs.

Are samples available for testing?

Sampling is generally restricted to pre-qualified partners due to IP protection. Evaluation kits may be accessible through official distribution channels upon submission of business credentials and intended use cases.

How to ensure compatibility with existing hardware?

Request full datasheets, pinout diagrams, power sequencing specifications, and BIOS configuration guidelines. Conduct interoperability testing using reference designs and confirm driver support for target operating systems prior to integration.