Modular Tool Storage Distributor

TR

TR

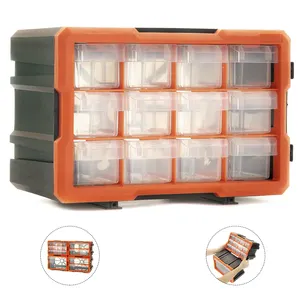

About modular tool storage distributor

Where to Find Modular Tool Storage Distributors?

China remains the global epicenter for modular tool storage manufacturing, with key supplier clusters concentrated in Zhejiang, Henan, and Anhui provinces. These regions host vertically integrated production ecosystems specializing in cold-rolled steel fabrication, powder coating, and flat-pack assembly—core competencies for high-durability modular systems. Proximity to steel mills and logistics hubs enables cost efficiency, with localized supply chains reducing material procurement lead times by 20–30% compared to offshore alternatives.

The industrial clusters support scalable output through automated stamping, CNC bending, and robotic welding lines, allowing suppliers to fulfill bulk orders (50+ sets) within 30–45 days. Buyers benefit from mature vendor networks where component sourcing, quality inspection, and export packaging are coordinated within tight geographic radii. This integration translates into consistent product uniformity, competitive pricing ($75–$2,350 per unit), and flexibility for both standardized and engineered-to-order configurations.

How to Choose Modular Tool Storage Distributors?

Evaluate potential partners using these critical criteria:

Material & Structural Integrity

Confirm use of cold-rolled steel (typically 0.8–1.5mm thickness) for load-bearing frames. Verify anti-corrosion treatments such as electrophoretic priming or powder coating. For heavy-duty applications, demand proof of static load testing (≥800kg per cabinet module) and structural weld integrity via visual or X-ray inspection reports.

Production Capacity Verification

Assess operational scale through measurable indicators:

- Minimum factory area exceeding 3,000m² for sustained volume output

- In-house capabilities including laser cutting, press braking, and surface finishing

- Dedicated R&D or engineering teams supporting custom design adaptation

Cross-reference declared capacity with on-time delivery performance (target ≥95%) and online transaction volume as proxies for order-handling reliability.

Customization & Compliance Readiness

Require documentation of customization scope: dimensional adjustments, color finishes (RAL/Pantone), labeling, locking mechanisms, sensor integration, and packaging formats. For international buyers, confirm adherence to destination-market safety and labeling standards (e.g., CE, GS). Prioritize suppliers offering pre-shipment sample validation and third-party QC audits upon request.

What Are the Leading Modular Tool Storage Distributors?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Luoyang Jin Feng Office Furniture Co., Ltd. | Henan, CN | Tool Cabinets, Workbenches, Steel Storage | US $460,000+ | 92% | ≤5h | 30% | Layout, color, packaging, logo, graphic, assembly, lock, sensor, wooden case | 50 pieces |

| Lu 'an Yinuo Machinery Equipment Co., Ltd. | Anhui, CN | Workstations (105), Tool Cabinets (82) | US $5,000+ | 25% | ≤3h | 25% | Modular configuration, steel gauge, finish | 1 set |

| Yongkang Youren Trading Co., Ltd. | Zhejiang, CN | Tool Cabinets (324), Tool Sets, Parts | US $180,000+ | 98% | ≤2h | <15% | Size, material, locking, layout | 1 set |

| Luoyang Wanyang International Trade Co., Ltd. | Henan, CN | Modular Workshops, Mechanic Benches | US $240,000+ | 91% | ≤2h | 25% | Color, material, shape, size, logo, label, graphic | 10–20 pieces/sets |

| Lu'an Arlott Composite Materials Technology Co., Ltd. | Anhui, CN | Heavy-Duty Trolleys, Cabinets | US $900,000+ | 99% | ≤1h | 18% | Color, material, size, logo, packaging, graphic | 1 set |

Performance Analysis

Lu'an Arlott stands out with a 99% on-time delivery rate and sub-1-hour response time, supported by robust customization infrastructure and the highest reported online revenue (US $900,000+), indicating strong market traction. Yongkang Youren demonstrates high operational discipline with 98% punctuality and extensive product specialization in tool cabinets (324 listings). Luoyang Jin Feng offers competitive MOQs (50 pieces) and broad customization, backed by a 30% reorder rate—suggesting solid customer retention despite longer response cycles. Notably, Lu 'an Yinuo reports only 25% on-time delivery, signaling potential fulfillment risks despite offering full-set configurations at low MOQs. Buyers prioritizing reliability should favor suppliers with verified delivery rates above 95% and responsive communication channels.

FAQs

How to verify modular tool storage supplier reliability?

Validate technical claims through facility videos, production line documentation, and sample testing. Check consistency in weld seams, drawer glide mechanics, and coating adhesion. Request references or third-party inspection reports (e.g., SGS) for large-volume orders. Analyze transaction history metrics such as on-time delivery and reorder rate as behavioral indicators of dependability.

What is the typical lead time for bulk orders?

Standard orders (10–50 sets) typically require 25–35 days for production and pre-shipment preparation. Customized configurations may extend lead times by 10–15 days depending on design complexity. Add 15–25 days for sea freight to North America or Europe.

Can suppliers accommodate OEM branding and packaging?

Yes, most established manufacturers support OEM services including custom logos, color schemes, user manuals, and retail-ready packaging. Minimum thresholds vary—some accept branding requests at 100 units, while others integrate it seamlessly even at 1-set MOQs.

Do modular tool storage suppliers offer free samples?

Sample policies differ. Some suppliers provide paid samples (refundable against future orders), while others charge full production cost upfront. Expect sample fees ranging from 1.5x to 2x unit price, with air freight billed separately. Full reimbursement is common upon placement of qualifying bulk orders.

What are standard payment terms?

Common terms include 30% T/T deposit with 70% balance before shipment. Larger buyers may negotiate LC at sight or escrow-based transactions for added security. Verified suppliers often participate in trade assurance programs that protect payments until delivery milestones are met.