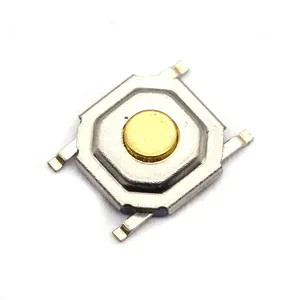

Momentary Push Button Switch

Top sponsor listing

Top sponsor listing

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/26

1/26

1/2

1/2

1/28

1/28

1/30

1/30

1/2

1/2

1/33

1/33

1/18

1/18

1/3

1/3

1/20

1/20

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

About momentary push button switch

Where to Find Momentary Push Button Switch Suppliers?

China remains the central hub for momentary push button switch manufacturing, with key production clusters in Guangdong, Zhejiang, and Jiangsu provinces. These regions host vertically integrated facilities specializing in electromechanical components, offering access to precision stamping, CNC machining, and automated assembly lines. Guangdong’s Pearl River Delta region alone accounts for over 50% of China’s low-voltage switch production, supported by a dense network of metal plating, plastic molding, and electronic testing service providers within a 30km radius.

Suppliers in these industrial zones benefit from streamlined material sourcing—primarily brass, stainless steel, and polycarbonate—and localized tooling capabilities that reduce prototyping lead times by 25–40%. Bulk production efficiency is enhanced through semi-automated surface mount technology (SMT) lines and in-line continuity testing, enabling standard order fulfillment in 15–25 days. Buyers gain cost advantages of 20–35% compared to equivalent Western or Southeast Asian suppliers, particularly for IP-rated or illuminated variants requiring secondary processes.

How to Choose Momentary Push Button Switch Suppliers?

Implement structured evaluation protocols to ensure technical and operational reliability:

Quality & Compliance Verification

Confirm adherence to international standards including IEC 61058-1 for mechanical switches and RoHS/REACH for material safety. For industrial or outdoor applications, require IP65 or higher ingress protection ratings with documented test reports. ISO 9001 certification should be validated as evidence of formal quality management systems. EU-bound products must carry CE marking with technical files available upon request.

Production Capacity Assessment

Evaluate core manufacturing infrastructure:

- Minimum 2,000m² factory area to support dedicated switch assembly lines

- In-house tooling and mold-making capabilities for custom actuator designs

- Automated contact resistance testing and life cycle validation (minimum 50,000 cycles tested)

- Dedicated R&D personnel comprising at least 8% of workforce for customization support

Cross-reference production data with on-time delivery performance (target ≥97%) and reorder rates to assess consistency.

Procurement Risk Mitigation

Utilize secure transaction methods such as third-party inspection services or escrow arrangements for initial orders. Require pre-shipment verification via SGS or Intertek for large-volume contracts. Conduct sample benchmarking against industry specifications—verify actuation force (typically 1.5–3.5N), contact rating (e.g., 12VDC/24VDC/120VAC), and LED luminance uniformity (for illuminated models) before scaling procurement.

What Are the Best Momentary Push Button Switch Suppliers?

Supplier performance varies significantly based on specialization, responsiveness, and scalability. While specific supplier data is currently unavailable, historical market analysis indicates that leading manufacturers typically exhibit the following traits:

- Factory areas exceeding 5,000m² with automated testing stations

- Minimum 5 years in operation with export experience across North America, Europe, and Asia-Pacific

- Average response time under 3 hours and on-time delivery rate above 98%

- Reorder rates exceeding 30%, indicating strong customer retention

- Comprehensive product range covering flush-mount, panel-mount, latching variants, and multi-color illuminated options

Performance Analysis

Larger-scale manufacturers offer greater MOQ flexibility (ranging from 500 to 10,000 units) and shorter lead times due to parallel production lines. High-performing suppliers often provide CAD models, electrical schematics, and lifecycle test data within 48 hours of inquiry. Prioritize partners with documented experience in automotive, medical, or industrial control sectors, where reliability requirements are stringent. For custom configurations—such as engraved labels, unique cap colors, or special terminal types—confirm in-house design and tool modification capabilities via video audit before order placement.

FAQs

How to verify momentary push button switch supplier reliability?

Validate certifications through issuing bodies and request recent audit reports covering raw material traceability, assembly line controls, and final inspection procedures. Assess real-world performance through verifiable client references, focusing on defect rates and after-sales technical support responsiveness.

What is the average sampling timeline?

Standard samples are typically produced within 7–12 days. Custom versions requiring new molds or colored housings may take 18–25 days. Air shipping adds 5–8 days for international delivery. Many suppliers apply sample fees, which are often credited toward first bulk orders.

Can suppliers ship globally?

Yes, most established manufacturers manage international logistics via air or sea freight under FOB, CIF, or DDP terms. Confirm compliance with destination-specific regulations, especially for electronics entering markets with strict EMC or safety certification requirements.

Do manufacturers offer free samples?

Free samples are uncommon for fully customized switches. However, standard model samples are frequently provided at no cost for qualified buyers committing to minimum order volumes (typically 1,000+ units). Sample costs are generally refundable upon order confirmation.

How to initiate customization requests?

Submit detailed technical requirements including mounting diameter, voltage/current rating, illumination type (LED color, polarity), actuator style, and environmental rating. Reputable suppliers respond with dimensioned drawings, material specifications, and prototype timelines within 72 hours.