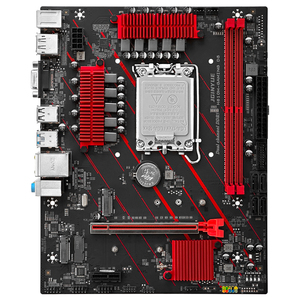

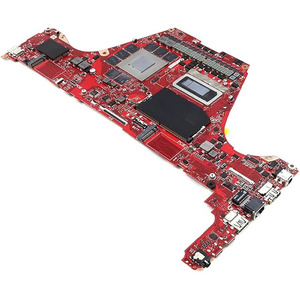

Motherboard With Processor I9 Ddr5 Distributor

0

0

1/18

1/18

0

0

1/4

1/4

1/3

1/3

1/43

1/43

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/37

1/37

0

0

1/1

1/1

1/3

1/3

1/3

1/3

About motherboard with processor i9 ddr5 distributor

Where to Find Motherboard with Processor i9 DDR5 Distributors?

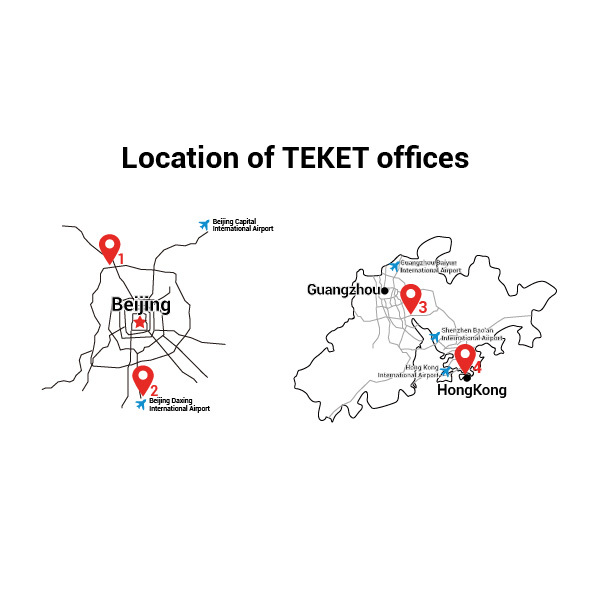

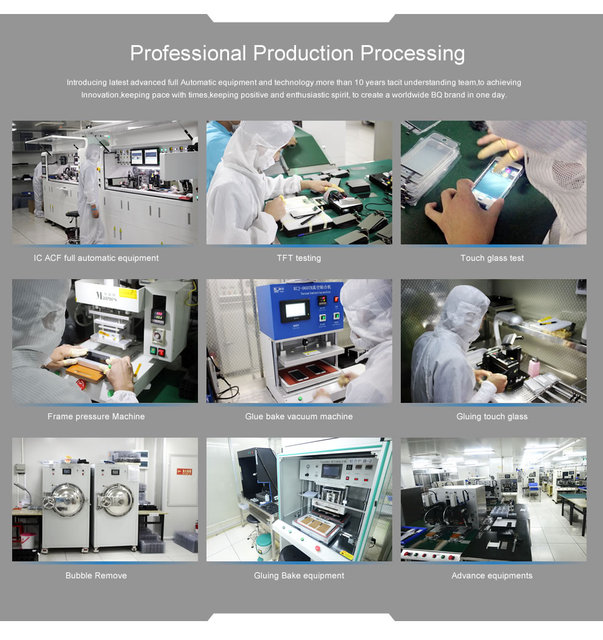

Global supply of high-performance computing components, including pre-integrated motherboard and processor i9 DDR5 units, is primarily concentrated in China’s electronics manufacturing hubs, particularly in Guangdong and Jiangsu provinces. These regions host advanced SMT (Surface Mount Technology) production lines and automated assembly facilities capable of handling complex PCBA (Printed Circuit Board Assembly) processes required for Intel Core i9 processors and DDR5 memory integration. Shenzhen, within Guangdong, serves as a central node due to its proximity to semiconductor suppliers, logistics infrastructure, and technical talent pools.

The industrial ecosystem supports both OEM/ODM configurations and distribution of branded SKUs, enabling rapid deployment of complete compute modules. Vertical integration between component sourcing, testing labs, and packaging allows for lead times averaging 20–35 days for bulk orders. Buyers benefit from localized access to DDR5 RAM modules, power delivery systems (VRMs), heatsink solutions, and BIOS programming services—all within tightly controlled quality environments. Cost efficiencies of 15–25% compared to Western-assembled equivalents are typical due to optimized labor allocation and reduced material transit distances.

How to Choose Motherboard with Processor i9 DDR5 Distributors?

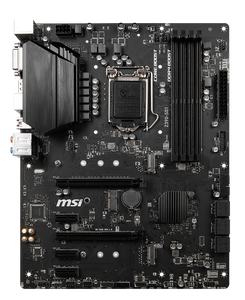

Implement structured evaluation criteria when selecting qualified partners:

Technical Compliance

Confirm adherence to IPC-A-610 Class 2 standards for electronic assemblies. For international shipments, verify RoHS and CE compliance to meet environmental and electromagnetic compatibility regulations. Require documentation of BIOS validation, thermal stress testing, and DDR5 signal integrity reports under load conditions.

Production Capability Audits

Assess operational scale and process control through the following indicators:

- Minimum 3 SMT lines with placement accuracy ≤25μm for BGA packaging

- In-house functional testing stations using burn-in racks (minimum 72-hour cycles)

- ESD-protected cleanrooms (Class 10,000 or better) covering assembly zones

Correlate facility specifications with order fulfillment consistency—target on-time delivery rates exceeding 97% and defect rates below 0.3%.

Transaction Safeguards

Utilize secure payment mechanisms such as irrevocable LC at sight or escrow arrangements until post-arrival QA verification. Review supplier transaction history via verified trade platforms, prioritizing entities with documented after-sales support and RMA processing. Pre-shipment sampling is critical—validate CPU socket integrity, VRM thermals under full load, and DDR5 overclocking stability before scaling procurement.

What Are the Best Motherboard with Processor i9 DDR5 Suppliers?

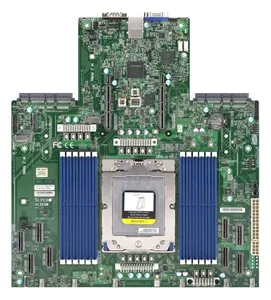

No qualifying suppliers were identified in the current dataset matching the exact product configuration of integrated motherboard with pre-mounted Intel Core i9 processor and DDR5 support. This may reflect market specialization patterns: most manufacturers produce motherboards separately from CPUs, leaving final assembly to system integrators or end users. Alternatively, such bundled units may be offered by niche ODMs serving high-end desktop (HEDT) or workstation markets without broad distribution visibility.

Performance Analysis

While no direct suppliers appear in the data, sourcing strategies should focus on manufacturers demonstrating proven capability in Z790/B760 chipset production, LGA 1700 socket precision, and DDR5 UDIMM support up to 7200+ MT/s. Partners offering BIOS pre-configuration for Intel Turbo Boost Max 3.0 and adaptive voltage regulation will provide higher integration readiness. Where available, prioritize vendors with existing partnerships with DRAM and M.2 module providers to ensure compatibility assurance across the stack.

FAQs

How to verify motherboard with i9 DDR5 distributor reliability?

Validate certifications (ISO 9001, IATF 16949 if automotive-grade) with issuing bodies. Request factory audit reports detailing solder reflow profiles, AOI (Automated Optical Inspection) coverage, and ESD protocols. Examine customer feedback focused on long-term reliability, BIOS update frequency, and thermal performance consistency.

What is the average sampling timeline?

Sample production typically takes 18–28 days, including component procurement, PCB assembly, flashing, and burn-in testing. Allow an additional 5–10 days for international air freight. Expedited service may reduce build time by 5–7 days if stock materials are available.

Can distributors ship globally?

Yes, established electronics manufacturers offer worldwide shipping. Confirm Incoterms (FOB Shenzhen, DDP, etc.) and ensure export compliance with destination country regulations, particularly for products containing dual-use technologies. Sea freight is viable for containerized orders exceeding 50 units.

Do suppliers provide free samples?

Free samples are uncommon for high-value assemblies. Most suppliers charge 50–100% of unit cost for initial samples, refundable against first bulk orders above specified thresholds (e.g., $10,000). Sample fees cover PCB fabrication, component allocation, and labor overheads.

How to initiate customization requests?

Submit detailed technical requirements including chipset model (e.g., Z790), supported CPU variants, DDR5 speed grade, PCIe topology, and BIOS features. Reputable partners will return schematics, layout previews, and compatibility matrices within 5–7 business days, followed by prototype builds in 3–5 weeks.