Motion Sensor Cam

1/12

1/12

1/3

1/3

1/1

1/1

1/2

1/2

1/3

1/3

1/20

1/20

1/6

1/6

1/16

1/16

1/19

1/19

1/3

1/3

1/3

1/3

1/20

1/20

1/3

1/3

1/2

1/2

1/3

1/3

CN

CN

1/19

1/19

1/3

1/3

1/25

1/25

About motion sensor cam

Where to Find Motion Sensor Cam Suppliers?

China remains the central hub for motion sensor camera manufacturing, with key production clusters in Guangdong, Zhejiang, and Jiangsu provinces. Guangdong—particularly the Shenzhen-Dongguan corridor—hosts over 70% of China’s smart surveillance equipment suppliers, supported by a mature electronics ecosystem that includes PCB fabrication, optical lens production, and firmware development. This integration enables rapid prototyping and high-volume assembly, reducing component procurement lead times by up to 40% compared to external supply chains.

These industrial zones feature vertically integrated operations, where injection molding, surface-mount technology (SMT) lines, and automated testing are conducted in-house. Proximity to tier-one component suppliers ensures consistent access to image sensors (e.g., CMOS), infrared emitters, and Wi-Fi/Bluetooth modules. Buyers benefit from economies of scale, with standard unit costs 25–35% below global averages, lead times averaging 20–35 days for MOQs of 500–1,000 units, and flexibility in both wireless (Wi-Fi/4G) and power-source configurations (battery, PoE, solar).

How to Choose Motion Sensor Cam Suppliers?

Implement structured evaluation criteria to ensure technical reliability and supply chain integrity:

Quality & Compliance Verification

Confirm adherence to ISO 9001 for quality management systems. For exports to North America and Europe, validate FCC, CE, and RoHS certifications to ensure electromagnetic compatibility, safety, and environmental compliance. Request test reports for IP ratings (e.g., IP65/IP66 for outdoor models) and low-light performance (minimum illumination levels in lux).

Production Capacity Assessment

Evaluate core infrastructure metrics:

- Minimum 3,000m² factory area with dedicated SMT and assembly lines

- In-house R&D capability, ideally with firmware and mobile app development teams

- Automated optical inspection (AOI) and 48-hour burn-in testing protocols

Cross-reference facility size with monthly output capacity (target: ≥10,000 units) and on-time delivery performance (benchmark: ≥97%).

Procurement Risk Mitigation

Utilize secure transaction methods such as third-party escrow or letter of credit (L/C) terms for initial orders. Prioritize suppliers with documented export experience to your target market, including customs documentation and labeling compliance. Conduct pre-shipment inspections via third-party auditors (e.g., SGS, TÜV) to verify functionality, packaging, and quantity accuracy. Pre-production sampling is critical—test video resolution, motion detection sensitivity, night vision range, and mobile app stability before scaling.

What Are the Best Motion Sensor Cam Suppliers?

Supplier data for motion sensor cameras is currently unavailable. However, sourcing strategies should focus on manufacturers demonstrating verifiable technical capabilities, certification transparency, and responsive communication. In absence of specific listings, buyers are advised to prioritize companies with:

- Proven track record in OEM/ODM smart security products

- Publicly accessible facility videos or virtual audit options

- Consistent response times under 4 hours and reorder rates exceeding 25%

- Comprehensive warranty policies (minimum 12 months) and multilingual technical support

Performance Analysis

While no supplier profiles are listed, historical trends indicate that manufacturers in Shenzhen and Zhongshan (Guangdong) lead in innovation velocity, offering AI-powered features such as human detection, two-way audio, and cloud storage integration. Factories with in-house mold-making and lens coating capabilities demonstrate higher customization agility. Prioritize partners with demonstrated scalability—evidenced by export volume and warehouse logistics—and those offering real-time project tracking during production runs.

FAQs

How to verify motion sensor cam supplier reliability?

Audit certification authenticity through issuing bodies and request full product compliance dossiers. Review third-party inspection reports covering material composition, electrical safety, and environmental testing. Analyze customer feedback on long-term device performance, firmware update frequency, and after-sales responsiveness.

What is the average sampling timeline?

Standard samples take 7–14 days to produce. Customized units with modified housings, extended battery life, or private-label firmware require 18–25 days. Air freight adds 5–10 days depending on destination. Sample costs typically reflect 40–60% of unit price, often credited toward bulk orders above 1,000 units.

Can suppliers ship motion sensor cams worldwide?

Yes, experienced exporters manage global logistics via air, sea, or express courier. Confirm Incoterms (e.g., FOB Shenzhen, CIF Rotterdam) and ensure packaging meets drop-test and moisture-resistance standards for international transit. Battery-equipped models must comply with IATA regulations for lithium-ion shipments.

Do manufacturers provide free samples?

Free samples are uncommon but negotiable for high-potential orders. Suppliers may waive fees if projected annual volume exceeds 5,000 units. Otherwise, expect to cover sample production and shipping costs, which can be reimbursed upon first full order fulfillment.

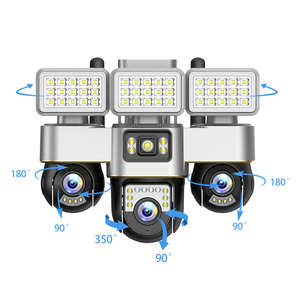

How to initiate customization requests?

Submit detailed specifications including desired resolution (1080p, 2K, 4K), field of view (90°–140°), connectivity (Wi-Fi 5/6, LTE), power type, housing material (ABS, metal), and branding requirements. Reputable suppliers will provide engineering feedback, 3D CAD models, and prototype timelines within 5 business days.