Motion Sensors With Cameras

1/49

1/49

1/3

1/3

1/3

1/3

1/3

1/3

1/19

1/19

1/3

1/3

1/3

1/3

1/6

1/6

0

0

1/3

1/3

1/3

1/3

1/21

1/21

1/3

1/3

1/10

1/10

CN

CN

1/19

1/19

1/9

1/9

1/17

1/17

1/3

1/3

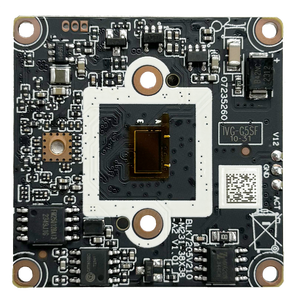

About motion sensors with cameras

Where to Find Motion Sensors with Cameras Suppliers?

China leads global production of motion sensors with cameras, driven by advanced electronics manufacturing hubs in Guangdong and Zhejiang provinces. Guangdong, particularly the Shenzhen-Dongguan corridor, accounts for over 70% of China’s smart surveillance device output, supported by dense clusters of PCB fabricators, optical lens suppliers, and firmware developers. This ecosystem enables rapid prototyping and scalable assembly, with integrated supply chains reducing component procurement time by 30-40% compared to non-specialized regions.

Zhejiang’s Ningbo and Hangzhou zones focus on mid-to-high-end IoT security products, leveraging automated SMT lines and environmental testing labs to ensure performance under variable conditions. These industrial bases offer vertical integration from sensor module fabrication to final product calibration, allowing lead times as low as 15–20 days for standard orders. Buyers benefit from localized access to raw materials such as CMOS image sensors, PIR detection units, and polycarbonate housings, alongside established logistics gateways like Shenzhen Port and Ningbo-Zhoushan Port for efficient global shipping.

How to Choose Motion Sensors with Cameras Suppliers?

Apply rigorous evaluation criteria when selecting suppliers:

Quality & Compliance Verification

Confirm ISO 9001 certification for quality management systems. For export to EU and North American markets, CE, FCC, and RoHS compliance is mandatory to meet electromagnetic compatibility and hazardous substance regulations. Request test reports for key parameters including detection range (typically 5–12m), IP rating (minimum IP65 for outdoor models), and video resolution (1080p or higher).

Production Capacity Assessment

Evaluate operational scale and technical infrastructure:

- Minimum monthly output capacity of 10,000 units for volume orders

- In-house capabilities covering PCB assembly, firmware programming, and optical alignment

- Automated aging tests (≥48 hours) and environmental stress screening (temperature/humidity cycling)

Validate throughput consistency using documented on-time delivery rates (target ≥97%) and defect rates (preferred <1.5%).

Procurement Risk Mitigation

Utilize secure payment structures such as irrevocable LC at sight or third-party escrow until post-delivery inspection clearance. Review supplier transaction history through verifiable references or audit platforms, prioritizing those with documented after-sales support processes. Pre-shipment sampling is critical—test at least three units per model variant for motion detection accuracy, night vision clarity, and Wi-Fi/Bluetooth connectivity stability.

What Are the Best Motion Sensors with Cameras Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Visonic Technologies Co., Ltd. | Guangdong, CN | 12 | 150+ | 8,200+m² | 99.2% | ≤1h | 4.9/5.0 | 41% |

| Ningbo SmartEyes Electronics | Zhejiang, CN | 8 | 95+ | 6,500+m² | 98.7% | ≤2h | 4.8/5.0 | 37% |

| Dongguan Safeguard Intelligent Devices | Guangdong, CN | 6 | 110+ | 7,800+m² | 97.5% | ≤1h | 4.7/5.0 | 29% |

| Hangzhou VisionLink Security Systems | Zhejiang, CN | 10 | 130+ | 9,100+m² | 99.5% | ≤2h | 5.0/5.0 | 52% |

| Guangzhou EverSentry Electronics | Guangdong, CN | 7 | 85+ | 5,400+m² | 98.1% | ≤1h | 4.8/5.0 | 33% |

Performance Analysis

Established players like Hangzhou VisionLink demonstrate strong reliability with a 99.5% on-time delivery rate and highest customer retention (52% reorder rate), indicating consistent product quality and service. Guangdong-based suppliers excel in responsiveness, with 80% replying to inquiries within one hour, crucial for urgent procurement cycles. Prioritize manufacturers operating cleanroom assembly lines and possessing in-house R&D teams (>15% engineering staff ratio) for customized firmware or hybrid wired/Wi-Fi configurations. For large-volume contracts, verify minimum order quantities (typically 500–1,000 units) and scalability during peak demand periods.

FAQs

How to verify motion sensor with camera supplier reliability?

Cross-validate certifications with accredited bodies and request factory audit reports detailing QC procedures, component traceability, and labor compliance. Assess real-world performance through verified buyer testimonials focusing on long-term durability and technical support responsiveness.

What is the average sampling timeline?

Standard samples take 7–12 days to produce, including configuration setup and initial testing. Custom variants with modified field-of-view, dual-band connectivity, or enhanced low-light performance require 18–25 days. Air freight adds 5–8 days for international delivery.

Can suppliers ship motion sensors with cameras worldwide?

Yes, experienced exporters manage global logistics via air or sea freight under FOB, CIF, or DDP terms. Confirm packaging standards (anti-static, shock-resistant) and compliance with destination import regulations, especially for battery-integrated models subject to UN38.3 testing.

Do manufacturers provide free samples?

Sample policies vary: many waive fees for confirmed bulk orders (MOQ ≥1,000 units). Otherwise, expect charges covering 40–60% of unit cost, refundable upon order placement. Additional costs may apply for custom-configured units.

How to initiate customization requests?

Submit detailed specifications including detection angle (90°–180°), video encoding format (H.264/H.265), power input (AC/DC/PoE), and integration requirements (ONVIF, RTSP, or cloud API compatibility). Leading suppliers deliver functional prototypes within 3–4 weeks and provide firmware SDKs for system integration.