Mpi Pcb Maker

Top sponsor listing

Top sponsor listing

CN

CN

1/18

1/18

CN

CN

1/20

1/20

1/61

1/61

CN

CN

1/52

1/52

1/31

1/31

1/34

1/34

1/24

1/24

About mpi pcb maker

Where to Find MPI PCB Maker Suppliers?

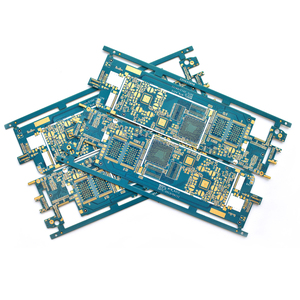

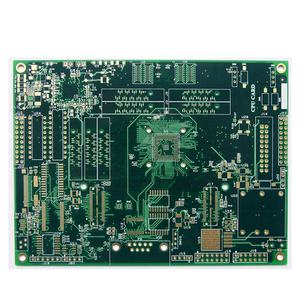

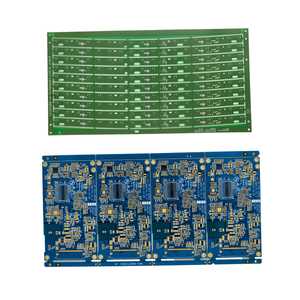

China remains the central hub for printed circuit board (PCB) manufacturing, with Shenzhen and Dongguan emerging as key industrial clusters for high-mix, low-volume (HMLV) and rapid prototyping services. These regions host vertically integrated facilities equipped with in-house production lines for PCB fabrication and assembly, enabling end-to-end control over quality and lead times. The concentration of technical talent, component suppliers, and logistics networks within the Pearl River Delta allows for streamlined operations, with average delivery cycles ranging from 5–15 days for prototype batches and 10–20 days for volume orders.

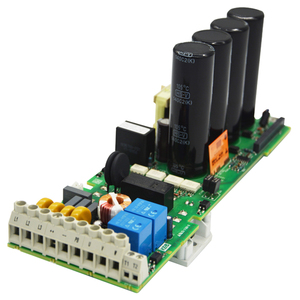

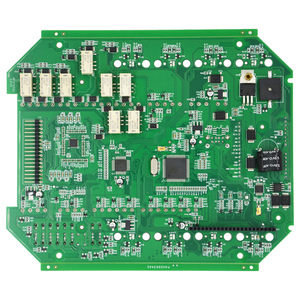

Suppliers specializing in MPI (multilayer printed interconnect) PCBs leverage advanced processing capabilities such as sequential lamination, blind/buried vias, impedance control, and HDI technology. Facilities typically support FR-4, Rogers, polyimide, and aluminum substrates, with layer counts ranging from 1 to 32+. Integration of SMT, DIP, wave soldering, and reflow technologies enables full turnkey PCBA services. Economies of scale, localized material sourcing, and automated production lines contribute to competitive pricing—often 20–35% below Western or Southeast Asian alternatives—while maintaining compliance with international standards.

How to Choose MPI PCB Maker Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to IPC-A-600/6012 (acceptability of printed boards) and ISO 9001-certified quality management systems. For electronics destined for EU or North American markets, RoHS and REACH compliance is mandatory. Request documentation for material traceability, solder mask integrity testing, and electrical performance validation (e.g., flying probe or fixture-based testing).

Production Capacity Assessment

Evaluate core manufacturing infrastructure through the following indicators:

- In-house production lines covering etching, plating, drilling, and surface finishing (HASL, ENIG, OSP)

- SMT lines with pick-and-place machines, reflow ovens, AOI inspection, and stencil printers

- Monthly output capacity exceeding 10,000 units for mid-tier suppliers

- Support for panelization, impedance matching, and controlled depth routing

Cross-reference on-time delivery rates (target ≥97%) and response time metrics to assess operational reliability.

Customization & Technical Support

Prioritize suppliers offering comprehensive design-for-manufacturability (DFM) feedback, Gerber file validation, and rapid prototyping (24–72 hour turnaround). Verify support for custom specifications including substrate material, copper thickness, thermal management, and mixed-technology assembly. Strong providers offer integrated solutions—from bare PCB fabrication to fully assembled and tested boards—with options for labeling, packaging, and serialization.

Transaction Security & Scalability

Analyze reorder rates and online transaction volume as proxies for customer satisfaction and financial stability. A reorder rate above 50% indicates consistent service quality. Use secure payment mechanisms and request sample batches before committing to large-scale production. Conduct virtual or on-site audits to verify factory size, equipment condition, and workforce expertise, particularly for high-reliability applications in automotive, medical, or industrial sectors.

What Are the Best MPI PCB Maker Suppliers?

| Company Name | Location | Verified Type | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Dongguan ICT Technology Co.,Ltd. | Guangdong, CN | Multispecialty Supplier | Electronics Production Machinery, Soldering Machines, Ultrasonic Cleaners | 100% | ≤3h | 100% | US $320,000+ | Color, material, size, logo, packaging, stencil printer, SMT solutions |

| Shenzhen Yidasheng Electronics Co., Ltd. | Shenzhen, CN | Multispecialty Supplier | Custom PCB, Fast Prototyping, ODM/OEM Boards | 100% | ≤2h | 33% | US $700+ | Color, material, size, logo, packaging, graphic |

| Toptek Pcb Co., Limited | Shenzhen, CN | Multispecialty Supplier | Custom PCB, PCBA, Wearable Electronics | 100% | ≤1h | 66% | US $1,000+ | Material, layer count, finish, assembly, packaging |

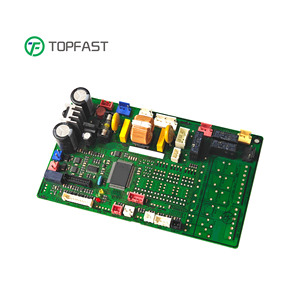

| Topfast Technology Co.,Ltd. | Shenzhen, CN | Custom Manufacturer | PCB Fabrication, PCBA Assembly, Prototype Services | 97% | ≤4h | 48% | US $610,000+ | Gerber files, RGB, hotswap, microcontrollers, design proofing |

| Shenzhen Quickpcb Circuit Co., Ltd. | Shenzhen, CN | Multispecialty Supplier | Rigid, Multilayer, Aluminum, Double-sided PCBs | 100% | ≤4h | 50% | US $900+ | Layer configuration, substrate type, surface finish |

Performance Analysis

Dongguan ICT Technology stands out with a 100% reorder rate and robust customization ecosystem, indicating strong client retention and process maturity. Toptek Pcb Co., Limited combines sub-1-hour responsiveness with a 66% reorder rate, suggesting efficient communication and consistent output quality. While Topfast Technology reports higher annual revenue (US $610,000+), its 97% on-time delivery rate warrants scrutiny for time-sensitive projects. Shenzhen-based suppliers dominate responsiveness and specialization in rapid-turn PCB services, with several offering prices as low as $0.01 per unit for simple designs at 1-piece MOQ. Buyers should prioritize partners with documented quality systems and verifiable production footage when scaling beyond prototype phases.

FAQs

How to verify an MPI PCB maker’s production capability?

Request facility videos showing cleanroom conditions, SMT line operations, and testing stations. Validate equipment lists (e.g., Yamaha/Siemens placement machines, DEK printers) and inquire about monthly throughput. Third-party audit reports or certifications (ISO 9001, IATF 16949) provide additional assurance.

What is the typical minimum order quantity (MOQ) for custom MPI PCBs?

Most suppliers offer 1-piece MOQ for prototypes and small batches. Volume pricing typically begins at 100–500 units, with progressive discounts up to 10,000+ units. Flexible MOQ policies are standard among Shenzhen-based manufacturers.

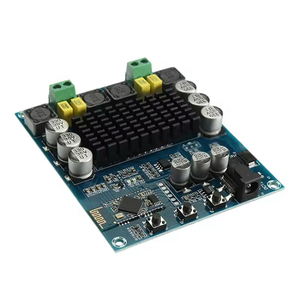

Do MPI PCB makers support full turnkey assembly?

Yes, leading suppliers provide turnkey PCBA services including component sourcing, BOM validation, solder paste printing, reflow, inspection, and functional testing. Some also offer firmware programming and final product packaging.

What are common lead times for MPI PCB production?

Standard lead time is 5–7 days for 2-layer prototypes and 7–12 days for multilayer (4–8 layer) boards. Expedited services (24–72 hours) are available at a premium. PCBA lead times add 3–5 days depending on complexity.

Can suppliers assist with PCB design and file preparation?

Reputable manufacturers offer free DFM checks, Gerber file validation, and design consultation. Advanced providers supply 3D renderings, impedance calculators, and stack-up planning tools to optimize manufacturability prior to production.