Nails Buffer Producer

1/17

1/17

1/3

1/3

1/17

1/17

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/39

1/39

1/17

1/17

0

0

1/16

1/16

1/19

1/19

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

About nails buffer producer

Where to Find Nails Buffer Producers?

China remains the dominant hub for nails buffer manufacturing, with key production clusters in Guangdong, Zhejiang, and Fujian provinces. These regions host vertically integrated facilities specializing in cosmetic tool fabrication, leveraging localized supply chains for foam, abrasive films, and EVA materials. Guangzhou and Foshan in Guangdong province are particularly notable for their concentration of OEM/ODM manufacturers equipped with in-house molding, lamination, and packaging lines, enabling end-to-end control over production cycles.

Suppliers in these industrial zones benefit from mature ecosystems that include raw material processors, print and labeling services, and export logistics providers operating within tight geographic proximity. This integration supports rapid prototyping and scalable output, with lead times averaging 15–25 days for bulk orders. Cost efficiencies are achieved through low material procurement costs and labor optimization, offering price competitiveness of 20–35% compared to Western or Southeast Asian producers. The presence of dedicated R&D teams at leading factories further enables customization in density, grit sequence, shape, and branding.

How to Choose Nails Buffer Producers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Production Capabilities

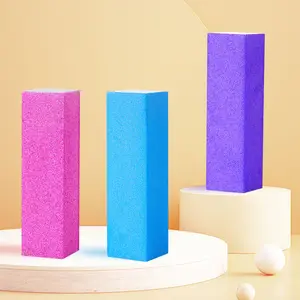

Prioritize manufacturers with confirmed in-house production lines, including foam die-cutting, multi-layer lamination, and automated packing. Facility size is indicative of scalability—suppliers with factory areas exceeding 3,000m² typically maintain buffer stocks and can accommodate large-volume orders (MOQs from 500 to 5,000 pieces). Confirm processing techniques such as ultrasonic welding for seamless blocks or precision grinding for calibrated abrasion gradients.

Quality Assurance & Compliance

While formal certifications (ISO 9001, CE, RoHS) are not universally declared in available data, performance indicators such as on-time delivery rates above 97% and response times under 4 hours correlate with robust internal quality systems. Suppliers reporting reorder rates below 15% may lack differentiation or consistent quality, whereas those offering customization options (color, logo, packaging, grit configuration) demonstrate greater process maturity and client focus.

Customization and Branding Flexibility

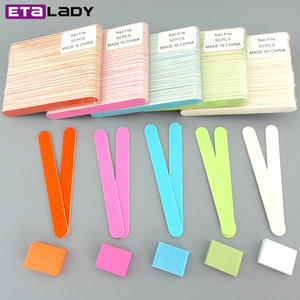

Leading producers support full OEM/ODM services, including:

- Custom foam densities (soft, medium, hard)

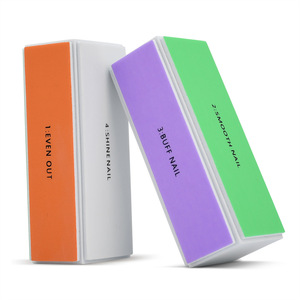

- Grit combinations (e.g., 100/180, 4-way, 7-step buffers)

- Shape and dimension adjustments (slim, ergonomic, mini formats)

- Logo printing, color-matching (Pantone), and retail-ready packaging

Verify graphic design support and minimum order thresholds for personalized elements, which typically start at 1,000 units for printed products.

Procurement Safeguards

Assess supplier reliability using verifiable metrics: on-time delivery performance, response time, and online transaction volume. Cross-reference product listings with sample availability and request physical prototypes before committing to bulk orders. Use secure payment mechanisms and confirm return policies for non-conforming goods. For high-volume contracts, prioritize suppliers with documented quality inspection protocols and third-party audit readiness.

What Are the Top Nails Buffer Producers?

| Company Name | Location | Type | Main Products | Customization Options | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Noval Medical Co., Ltd. | Guangdong, CN | Custom Manufacturer | Double-side, sponge, mini, custom 4-side blocks | Color, material, size, logo, packaging, label, graphic | 100% | ≤3h | US $450,000+ | <15% |

| Xiamen Foot Nice Pumice Industry & Trade Co., Ltd. | Fujian, CN | Custom Manufacturer | EVA, 4-way, professional shiny blocks, OEM designs | Color, material, size, logo, packaging, buffer label, graphic | 97% | ≤6h | US $510,000+ | <15% |

| Dongyang Aimei Nail Products Co., Ltd. | Zhejiang, CN | Custom Manufacturer | Polishing shiners, 7-way buffers, multi-color packs | Color, material, size, logo, packaging, label, graphic | 96% | ≤5h | US $110,000+ | <15% |

| Foshan Yuli Cosmetic Supplies Co., Ltd. | Guangdong, CN | Multispecialty Supplier | 4-step, OEM logo, professional shiny buffers | Color, material, shape, size, logo, packaging, label, graphic | 98% | ≤4h | US $130,000+ | 18% |

| NEO DEVELOPMENT JOINT STOCK COMPANY | Vietnam | Nail Accessories Supplier | Slim, soft, premium sponge buffers, mini blocks | Data unavailable | Not reported | ≤7h | Not reported | Not reported |

Performance Analysis

Guangzhou Noval Medical leads in reliability with a perfect 100% on-time delivery rate and fast ≤3-hour response time, backed by strong revenue performance and comprehensive customization capabilities. Xiamen Foot Nice stands out for high transaction volume (US $510,000+) and large MOQ capacity, suitable for distributors requiring bulk inventory. Dongyang Aimei offers competitive pricing and agile communication but slightly lower fulfillment consistency. Foshan Yuli distinguishes itself with shape customization and a higher reorder rate (18%), suggesting stronger customer retention. NEO Development lacks transparency in delivery and financial metrics, increasing procurement risk despite product diversity.

FAQs

What is the typical MOQ for nail buffer producers?

Minimum order quantities vary by design and complexity: standard sponge buffers start at 500–1,000 pieces, while customized or printed versions typically require 1,000–5,000 units. Mini or multi-pack formats may have higher thresholds due to packaging logistics.

How long does production and shipping take?

Manufacturing lead time ranges from 15 to 25 days after sample approval. Air freight adds 5–10 days for international delivery, while sea shipping takes 25–40 days depending on destination. Expedited production (7–10 days) is available from select suppliers at a premium.

Do suppliers provide free samples?

Most manufacturers offer samples for evaluation, though buyers often cover shipping costs. Some waive fees for qualified buyers with confirmed purchase intent. Custom samples may incur a nominal charge, refundable against future orders.

Can I customize the grit sequence and color coding?

Yes, leading producers allow full specification of abrasive gradations (e.g., 100/180/240/400) and corresponding color schemes. Suppliers provide technical guidance on optimal sequences for natural nail care, acrylic removal, or polishing stages.

What payment terms are common among nail buffer producers?

Standard terms include 30% deposit with balance paid before shipment. Established buyers may negotiate LC at sight or use platform-based escrow services for transaction security. Larger suppliers may offer net-30 arrangements upon credit verification.