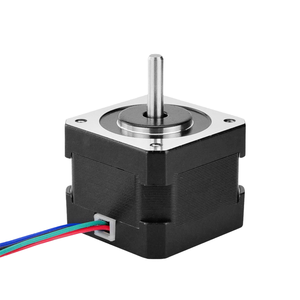

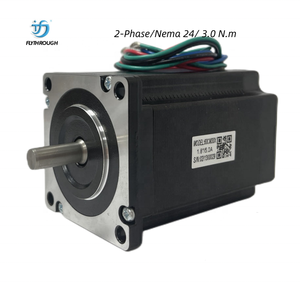

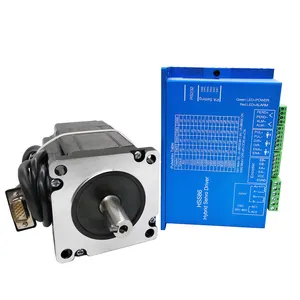

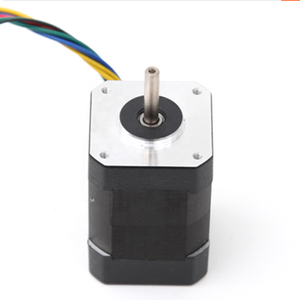

Nema Stepper Motor Producer

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/38

1/38

1/40

1/40

0

0

1/3

1/3

1/17

1/17

1/3

1/3

1/23

1/23

1/3

1/3

1/21

1/21

1/3

1/3

1/3

1/3

About nema stepper motor producer

Where to Find NEMA Stepper Motor Producers?

China remains the central hub for NEMA stepper motor manufacturing, with concentrated production clusters in Zhejiang, Jiangsu, and Guangdong provinces. These regions host vertically integrated facilities that combine precision machining, coil winding, magnetic assembly, and final testing under one roof. Zhejiang’s Ningbo and Wenzhou zones specialize in high-volume production of NEMA 17, 23, and 34 motors, leveraging proximity to rare-earth magnet suppliers and CNC component manufacturers. Guangdong’s Pearl River Delta offers advanced automation integration, enabling rapid prototyping and customization for export markets.

The industrial ecosystems support economies of scale, with many producers maintaining monthly outputs exceeding 50,000 units. Localized supply chains reduce material lead times by 25–40% compared to offshore alternatives, while shared technical labor pools enhance production flexibility. Buyers benefit from consolidated sourcing networks where motor windings, bearings, shafts, and enclosures are sourced within 30km, minimizing logistics overhead. Typical advantages include lead times of 15–30 days for standard models, 18–25% lower unit costs due to reduced labor and material expenses, and scalable capacity for OEM/ODM orders.

How to Choose NEMA Stepper Motor Producers?

Implement structured evaluation criteria to ensure supplier reliability and technical alignment:

Quality & Compliance Verification

Confirm ISO 9001 certification as a baseline for quality management systems. For European and North American markets, CE, RoHS, and REACH compliance are mandatory for electromagnetic equipment. Request test reports for insulation resistance (≥100MΩ at 500VDC), dielectric strength (1,500VAC for 1 minute), and temperature rise (≤80K under rated current). Verify traceability of raw materials—especially copper wire grade (typically 100% pure electrolytic) and neodymium magnet specifications (N35–N52).

Production Capability Assessment

Evaluate key infrastructure indicators:

- Minimum factory area of 3,000m² to support automated assembly lines

- In-house coil winding and rotor magnetization capabilities

- Dedicated R&D team (minimum 8% of total staff) for custom torque-speed curve development

Cross-check production videos with order fulfillment history, targeting on-time delivery rates above 96%. Confirm batch testing protocols using dynamometers and LCR meters.

Procurement Risk Mitigation

Utilize secure payment structures such as irrevocable LC or escrow arrangements until product verification is complete. Require sample validation against NEMA ICS 16-2018 standards for frame dimensions, shaft runout (<0.03mm), and holding torque tolerance (±10%). Prioritize suppliers with documented export experience to your target market, including HS code classification (8501.10) and customs documentation support.

What Are the Best NEMA Stepper Motor Producers?

No supplier data is currently available for analysis. Procurement teams should initiate targeted sourcing inquiries through verified trade directories and industry exhibitions such as the China International Machine Tool Show (CIMT) or Electronica China. Focus on companies demonstrating compliance documentation, facility audits, and product test reports during initial engagement.

Performance Analysis

In absence of specific supplier profiles, emphasis should be placed on operational transparency and technical documentation. Established producers typically demonstrate consistent on-time delivery (>97%), maintain response times under 4 hours, and provide detailed CAD models and performance curves upon request. Newer entrants may offer competitive pricing but require closer scrutiny of quality control processes and long-term durability testing. Prioritize manufacturers with proven track records in servo-system integration and motion control applications across automation, medical devices, and CNC machinery sectors.

FAQs

How to verify NEMA stepper motor producer reliability?

Validate certifications through accredited bodies such as SGS, TÜV, or BV. Request factory audit reports covering process controls, environmental management (ISO 14001), and worker safety (OHSAS 18001). Analyze customer references focusing on field failure rates, thermal stability under continuous load, and after-sales technical support responsiveness.

What is the average sampling timeline?

Standard samples take 7–14 days for production. Custom configurations requiring modified windings, special shafts, or IP-rated housings extend lead time to 20–28 days. Air freight adds 5–9 days depending on destination region.

Can NEMA stepper motor producers ship globally?

Yes, most exporters support international shipping via air or sea freight. Confirm Incoterms (FOB, CIF, DDP) and packaging standards (anti-static, moisture-resistant) for sensitive components. Full-container loads (FCL) are cost-effective for orders exceeding 5,000 units.

Do manufacturers provide free samples?

Sample policies vary. Reputable producers often waive fees for qualified buyers committing to minimum order quantities (MOQ ≥ 500 units). Otherwise, expect to cover 40–60% of unit cost, refundable against first production batch.

How to initiate customization requests?

Submit detailed technical requirements including step angle (1.8° or 0.9°), voltage/current ratings, lead configuration (4, 6, or 8 leads), shaft type (round, D-cut, double), and environmental protection level (IP54/IP65). Leading suppliers deliver engineering drawings within 48 hours and functional prototypes in 3–5 weeks.