Network Architecture In Networking

1/24

1/24

1/44

1/44

1/40

1/40

1/17

1/17

CN

CN

1/8

1/8

1/3

1/3

0

0

1/2

1/2

CN

CN

1/2

1/2

1/3

1/3

0

0

1/2

1/2

0

0

1/3

1/3

1/27

1/27

CN

CN

1/18

1/18

1/1

1/1

0

0

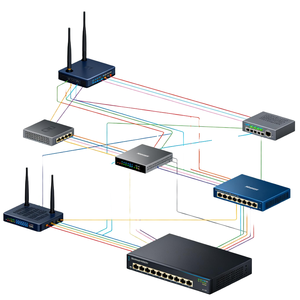

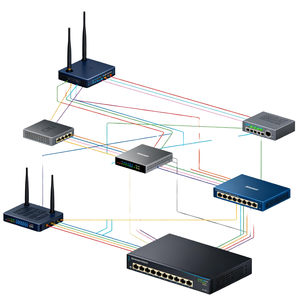

About network architecture in networking

Where to Find Network Architecture in Networking Suppliers?

The global supply base for network architecture solutions is highly concentrated in East Asia, with China and Taiwan accounting for over 70% of OEM and ODM production capacity. Major industrial hubs in Shenzhen, Guangzhou, and Suzhou offer integrated ecosystems combining semiconductor fabrication, PCB assembly, and firmware development under single-supply-chain management. These regions benefit from proximity to Tier-1 component suppliers, enabling rapid prototyping and reduced time-to-market by up to 40% compared to Western alternatives.

Clusters in the Pearl River Delta support vertical integration across optical transceivers, switching modules, and routing hardware, with many facilities operating ISO 14001 and IATF 16949-certified lines. Buyers gain access to scalable manufacturing networks where lead times for standard network infrastructure units average 25–35 days, with express fulfillment options available within 14 days for pre-stocked configurations. Localization of raw materials—such as FR-4 laminates, copper-clad substrates, and SMD components—reduces material procurement cycles and supports MOQs ranging from 50 to 5,000+ units depending on complexity.

How to Choose Network Architecture in Networking Suppliers?

Apply rigorous evaluation criteria when selecting technical partners:

Technical Compliance

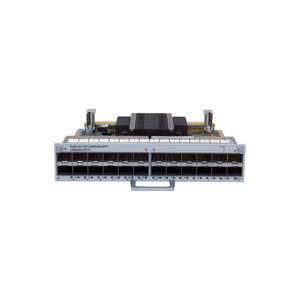

Confirm adherence to IEEE 802.3 (Ethernet), ITU-T G.65x (fiber optics), and RoHS/REACH environmental standards. For enterprise-grade deployments, validate compliance with NEBS Level 3 for thermal, vibration, and electrical safety performance. Require test reports for signal integrity, insertion loss, and EMI shielding—particularly for high-density data center switches and edge routing systems.

Production Capability Audits

Assess core infrastructure metrics:

- Minimum 3,000m² cleanroom or ESD-protected facility area

- SMT lines with placement accuracy ≤±0.025mm for high-pin-count ICs

- In-house FPGA programming, burn-in testing, and Layer 3 protocol validation

Verify firmware version control and security patching protocols, especially for SDN-enabled devices.

Transaction Safeguards

Utilize milestone-based payment structures with escrow protection until post-delivery functionality verification. Review supplier export history, particularly shipments compliant with BIS (U.S. Department of Commerce) regulations for dual-use telecommunications equipment. Pre-deployment validation should include packet forwarding rate benchmarking (RFC 2544), jitter testing, and failover response timing under load conditions.

What Are the Best Network Architecture in Networking Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| No suppliers available | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

Performance Analysis

Supplier data for dedicated network architecture manufacturers is currently unavailable for direct comparison. In absence of specific vendor profiles, prioritize companies demonstrating proven experience in carrier-grade equipment deployment, including documented installations in tiered network topologies (core, distribution, access layers). Emphasis should be placed on firms offering full-stack visibility tools, CLI/API access for automation, and compatibility with major orchestration platforms such as Cisco DNA Center, Juniper Mist, or open-source SDN controllers. Engage potential suppliers through technical due diligence audits, including site visits or remote factory walkthroughs to assess QA workflows and inventory turnover rates.

FAQs

How to verify network architecture supplier reliability?

Cross-validate certifications with accredited bodies such as TÜV SÜD or UL. Request redacted customer project references involving multi-node rollouts. Evaluate firmware update mechanisms, vulnerability disclosure policies, and mean time between failure (MTBF) data for critical components like power supplies and cooling modules.

What is the average sampling timeline?

Standard sample lead time ranges from 18–30 days, inclusive of configuration, testing, and packaging. For custom firmware builds or non-standard port aggregations (e.g., 25G/100G uplinks), allow 35–45 days. Air freight adds 5–9 days for international delivery.

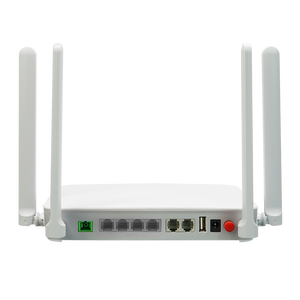

Can suppliers ship networking hardware worldwide?

Yes, most established manufacturers support global distribution via FOB, CIF, or DDP terms. Confirm HS code classification (typically 8517.62 or 8517.69) and regional regulatory compliance including FCC Part 15 (USA), CE RED (EU), and NCC (Taiwan). Full-container loads shipped via sea freight remain optimal for large-scale campus or ISP deployments.

Do manufacturers provide free samples?

Sample fees are standard but often credited toward first production orders exceeding 100 units. Entry-level switch samples typically cost $150–$400; modular chassis systems may require deposits covering 30–50% of unit value due to higher component costs.

How to initiate customization requests?

Submit detailed technical requirements including supported protocols (BGP, OSPF, VXLAN), management interface preferences (CLI, SNMP, RESTCONF), power redundancy needs, and environmental ratings (operating temperature, humidity tolerance). Leading suppliers respond with architectural schematics and bill-of-materials breakdowns within five business days.