New Key Maker

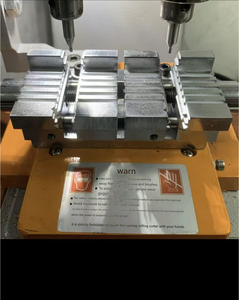

About new key maker

Where to Find New Key Maker Suppliers?

China remains the central hub for new key maker manufacturing, with supplier clusters concentrated in Henan, Guangdong, and Zhejiang provinces. These regions host vertically integrated production ecosystems that combine precision machining, electronics integration, and locksmith tool engineering. Henan-based suppliers dominate volume output, leveraging proximity to steel and casting raw materials, while Shenzhen and Yiwu facilities specialize in compact, portable key cutting systems with embedded digital programming capabilities.

The industrial advantage lies in localized supply chains—components such as servo motors, clamping jaws, and encoder sensors are sourced within 50km of assembly plants, reducing lead times by 20–30%. Most factories operate automated CNC machining lines capable of producing 300–500 units monthly per model. Buyers benefit from scalable production, with standard delivery windows averaging 15–25 days post-order confirmation. The ecosystem supports both mass production (MOQs from 1–2 sets) and technical customization, including firmware adaptation and ergonomic redesigns.

How to Choose New Key Maker Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify adherence to international electrical safety standards (CE, RoHS) for programmable models. For professional-grade equipment, confirm inclusion of overload protection, vibration damping, and micron-level cutting accuracy (±0.02mm). Request documentation on motor lifespan testing (minimum 5,000-hour endurance) and software version control, particularly for key programmers with cloud-based code libraries.

Production and Customization Capacity

Assess supplier capability through the following indicators:

- In-house CNC and laser calibration systems for consistent tool alignment

- Dedicated R&D teams supporting firmware updates and interface localization

- Customization scope covering color, branding, packaging, and functional modules (e.g., Bluetooth connectivity, battery type)

Cross-reference online revenue data and reorder rates as proxies for product reliability and market acceptance. Prioritize suppliers with ≥97% on-time delivery and response times under 4 hours.

Transaction and Quality Assurance

Utilize secure payment mechanisms such as escrow services to mitigate risk. Demand sample testing before bulk orders—evaluate cut precision across multiple blank types (e.g., Lishi, Tibbe, VAT) and assess software stability during repeated programming cycles. Confirm post-sale support availability, especially for firmware troubleshooting and spare part replacement.

What Are the Best New Key Maker Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Main Product Focus | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Gongyi City Jingying Machinery Manufacturing Factory | Henan, CN | US $510,000+ | 96% | ≤4h | 28% | Color, material, logo, packaging, label, graphic | Key cutting machines, tank-style duplicators | 1–2 sets |

| Henan Locks Trading Co., Ltd. | Henan, CN | US $210,000+ | 99% | ≤1h | 18% | Color, material, logo, packaging, label, graphic | Portable key cutters, smart locksmith tools | 1–2 pieces/sets |

| Shenzhen Topbest Technology Co., Limited | Guangdong, CN | US $430,000+ | 99% | ≤3h | 32% | Color, size, logo, packaging, car/motorcycle key compatibility | Manual and semi-automatic key machines | 1–2 pieces |

| Shenzhen Deyixing Technology Co., Ltd. | Guangdong, CN | US $20,000+ | 97% | ≤3h | <15% | Limited (focused on diagnostic integration) | Smart key programmers, multi-functional tools | 1–5 sets |

| Yiwu Tonghe Imp. & Exp. Trading Firm | Zhejiang, CN | US $20,000+ | 94% | ≤6h | <15% | Basic customization available | Horizontal and electric key duplicators | 1–2 sets/pieces |

Performance Analysis

High-performing suppliers like Gongyi City Jingying and Shenzhen Topbest combine strong reorder rates (28–32%) with extensive customization, indicating customer satisfaction and market adaptability. Henan Locks Trading stands out for responsiveness (≤1h average reply), a critical factor for urgent procurement cycles. While Shenzhen Deyixing offers advanced diagnostic-integrated models, its lower reorder rate suggests potential gaps in after-sales service or reliability consistency. Yiwu Tonghe, though less specialized in locksmith tools, provides competitively priced entry-level machines suitable for small workshops. Buyers prioritizing durability and support should favor suppliers with proven track records (≥97% on-time delivery) and higher transaction volumes.

FAQs

How to verify new key maker supplier reliability?

Cross-check declared certifications (CE, RoHS) with public databases. Analyze supplier performance metrics: prioritize those with ≥97% on-time delivery and reorder rates above 25%. Request video audits of production lines and test samples under real-world conditions before committing to large orders.

What is the typical sampling timeline for key makers?

Standard sample production takes 7–14 days, depending on complexity. Portable or programmable models may require up to 20 days if firmware customization is involved. Air shipping adds 5–10 days for international delivery.

Can suppliers ship new key makers globally?

Yes, most manufacturers offer FOB and CIF shipping terms with global logistics partners. Confirm compliance with destination regulations, especially for electronic components requiring import declarations. Sea freight is cost-effective for container loads; air express suits sample or urgent single-unit shipments.

Do suppliers provide free samples?

Free samples are rare for high-value machinery. Most suppliers charge 30–70% of unit cost for samples, which may be credited toward future bulk orders. Waivers typically apply only to repeat buyers or orders exceeding five units.

How to initiate customization requests for key makers?

Submit detailed specifications including machine dimensions, voltage requirements (110V/220V), preferred user interface language, and branding elements (logo placement, color scheme). Reputable suppliers respond with technical drawings within 72 hours and deliver prototypes in 2–3 weeks.