Note 10 Plus Screen Producer

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/22

1/22

1/21

1/21

1/24

1/24

1/31

1/31

1/3

1/3

1/15

1/15

1/5

1/5

1/15

1/15

1/3

1/3

About note 10 plus screen producer

Where to Find Note 10 Plus Screen Producers?

China remains the central hub for aftermarket mobile phone display manufacturing, with Shenzhen and Guangzhou forming key industrial clusters for high-volume OEM and replacement screen production. These regions host vertically integrated supply chains specializing in AMOLED, Super AMOLED, and INCELL OLED technologies used in premium smartphones such as the Samsung Galaxy Note 10 Plus. Proximity to component suppliers—glass manufacturers, IC vendors, and flex cable producers—enables rapid prototyping and cost-efficient assembly, reducing material lead times by up to 40% compared to offshore alternatives.

Suppliers in this ecosystem typically operate dedicated production lines focused on touchscreen modules, integrating front glass, digitizer, and display panels into fully tested assemblies. Many maintain in-house testing protocols using automated optical inspection (AOI) systems and electrical burn-in cycles to verify color accuracy, touch responsiveness, and signal integrity before shipment. This localized infrastructure supports both bulk procurement and low-MOQ sampling, making it ideal for repair shops, distributors, and private-label operators seeking scalable sourcing solutions.

How to Choose Note 10 Plus Screen Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Production Capability Verification

Confirm that suppliers possess proprietary production lines rather than functioning solely as resellers. Key indicators include consistent product specifications across multiple listings and references to internal testing procedures. Prioritize companies advertising "own production line" in their keywords, as this implies control over quality consistency, defect rates, and customization potential.

Quality Assurance Metrics

Evaluate performance data points embedded in supplier profiles:

- On-time delivery rate ≥98% indicates reliable logistics execution

- Response time ≤5 hours reflects strong customer engagement capacity

- Reorder rate below 33% may suggest limited customer retention or niche market positioning

While formal certifications like ISO 9001 or RoHS compliance are rarely published at the component level, verified on-time delivery and testing claims serve as proxy indicators of process discipline.

Order Flexibility & Risk Mitigation

Assess minimum order quantities (MOQs), pricing tiers, and sample availability. Several top-tier suppliers offer MOQs as low as 1 piece, enabling pre-bulk validation. Leverage platform-based transaction safeguards where available, including escrow payment systems and dispute resolution mechanisms. Always request samples prior to volume orders to evaluate brightness uniformity, touch sensitivity, and adhesive application quality under real-world conditions.

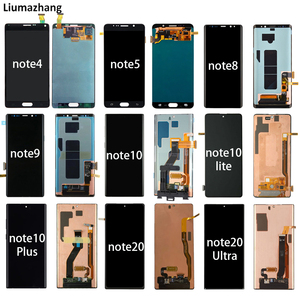

What Are the Leading Note 10 Plus Screen Producers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

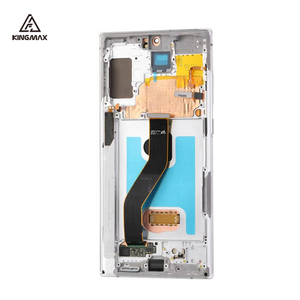

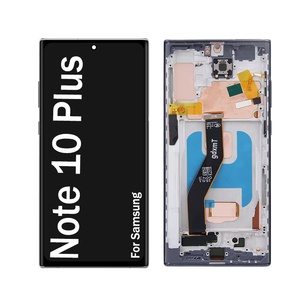

| Shenzhen Kingmax Technology Co., Ltd. | Shenzhen, CN | Mobile Phone LCDs, Repair Tools, Flex Cables | $54–139.90 | 1 piece | 98% | ≤5h | <15% | US $80,000+ |

| Guangzhou Bosby Electronics Co., Ltd. | Guangzhou, CN | LCDs, Motherboards, Housings, Batteries | $32.99–116.99 | 2 units | 91% | ≤3h | <15% | US $20,000+ |

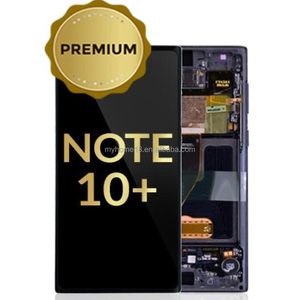

| Shenzhen Myhome Technology Co., Ltd. | Shenzhen, CN | LCDs, VR Hardware, Cases, Chargers | $39.80–198.90 | 2 pieces | 100% | ≤6h | 33% | US $20,000+ |

| Shenzhen Heshunyi Technology Limited | Shenzhen, CN | LCDs, Housings, Monitors, Flex Cables | $10–50 | 1 piece | 100% | ≤18h | 40% | US $40,000+ |

| Shenzhen Paqi Technology Co., Ltd. | Shenzhen, CN | Housings, LCDs, Memory Cards, Batteries | $6.60–9.90 | 10 pieces | 75% | ≤11h | 33% | US $3,000+ |

Performance Analysis

Shenzhen Kingmax stands out for balancing high on-time delivery (98%) with a one-piece MOQ and sub-5-hour response time, making it optimal for small-scale buyers requiring reliability. Guangzhou Bosby offers competitive pricing starting at $32.99 with fast communication but slightly lower fulfillment performance (91%). Shenzhen Myhome and Heshunyi report perfect on-time delivery records, though Heshunyi’s higher reorder rate (40%) suggests stronger post-sale satisfaction despite slower average responses. Notably, Paqi Technology lists unusually low prices ($6.60/unit) but pairs them with a 10-piece MOQ and the lowest delivery reliability (75%), indicating elevated risk for time-sensitive operations. Buyers should prioritize suppliers with documented testing processes—such as “100% Tested” or “Burn-in Verified”—to minimize return rates due to pixel defects or touch calibration issues.

FAQs

What is the typical lead time for Note 10 Plus screens?

Standard orders from verified suppliers ship within 3–7 business days after payment confirmation. Custom packaging or private labeling may extend processing by 2–4 days. Air freight adds 5–10 days for international delivery depending on destination region.

Do suppliers provide tested or untested units?

Top-tier producers advertise “100% tested” or “burn-in verified” units, ensuring functional integrity prior to dispatch. Lower-priced listings may not specify testing status, increasing the likelihood of DOA (dead-on-arrival) units. Always confirm testing protocols before purchase.

Can I request custom branding or packaging?

Yes, many manufacturers support OEM/ODM services, including logo printing, retail box design, and anti-static bag labeling. Minimum requirements vary—typically 50–100 units per configuration—with additional lead time of 5–7 days.

Are there differences between original and OEM screens?

Original (genuine recycled) screens are harvested from decommissioned devices and retain factory calibration, while OEM versions replicate functionality using third-party materials. OEM units generally cost 30–50% less but may exhibit minor variances in contrast ratio or auto-brightness behavior.

How to reduce defect risks when sourcing in bulk?

Implement a tiered approach: first procure samples from three shortlisted suppliers, conduct side-by-side performance evaluations, then initiate trial batches of 10–20 units. Inspect for uniform backlighting, dead pixels, touch lag, and frame adhesion quality. Use results to finalize vendor selection before scaling to full-volume orders.