Notebook Factory

1/24

1/24

1/6

1/6

1/6

1/6

0

0

1/26

1/26

0

0

1/15

1/15

1/3

1/3

1/15

1/15

1/26

1/26

1/25

1/25

1/8

1/8

1/31

1/31

About notebook factory

Where to Find Notebook Factory Suppliers?

China remains the global epicenter for notebook manufacturing, with key production clusters concentrated in Guangdong, Anhui, and Shenzhen regions. These hubs host vertically integrated facilities capable of end-to-end production—from paper sourcing and cover lamination to binding, packaging, and custom branding. Dongguan and Shenzhen specialize in premium stationery products with advanced customization capabilities, while Hefei-based factories focus on high-volume output of standard exercise books and school supplies at competitive unit costs.

The industrial ecosystem enables rapid prototyping and scalable production runs, supported by localized access to raw materials such as PU leather, recycled paper, and synthetic binding components. Factories in these zones typically operate automated assembly lines with monthly outputs ranging from 500,000 to over 2 million units, ensuring short lead times (15–25 days for bulk orders) and cost efficiency. Proximity to Shenzhen and Nansha ports further enhances export logistics, reducing transit time for international buyers.

How to Choose Notebook Factory Suppliers?

Effective supplier selection requires rigorous evaluation across three core dimensions:

Production Capability Verification

Confirm suppliers possess in-house production lines for critical processes including hot-stamping, embossing, spiral binding, and die-cutting. Minimum viable factory size should exceed 3,000m² with dedicated quality control stations. Prioritize partners offering digital proofing and sample production within 7–10 days. Cross-reference declared output capacity with actual online transaction volume—suppliers reporting annual revenues exceeding US $3 million demonstrate proven scalability.

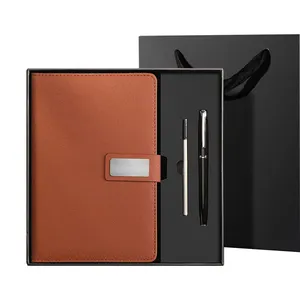

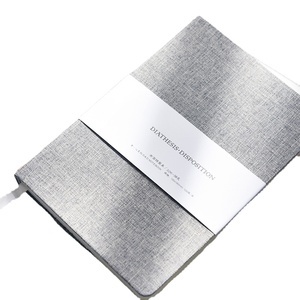

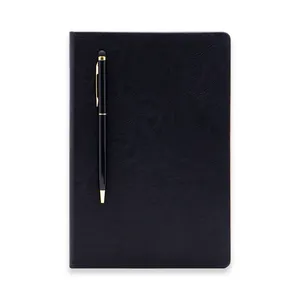

Customization & Material Flexibility

Assess technical scope for personalization:

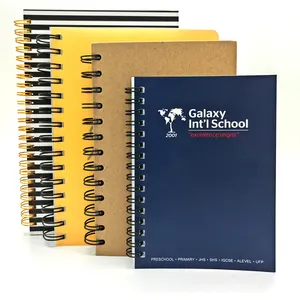

- Material options: PU leather, recycled cardboard, fabric covers, kraft paper

- Binding types: Spiral, perfect, saddle-stitch, elastic closure

- Finishing techniques: Foil stamping, debossing, engraving, heat transfer, color printing

- Design integration: Custom logo placement, full-wrap graphics, page layout configuration

Ensure suppliers support vector-based artwork submission and provide pre-production mockups.

Quality Assurance & Transaction Reliability

While formal ISO certification is not universally declared, evaluate performance metrics where available. Target suppliers with on-time delivery rates ≥96% and response times under 4 hours. Reorder rates above 25% indicate customer satisfaction and product consistency. For large-volume procurement, require batch sampling and third-party inspection prior to shipment. Confirm packaging standards (inner boxes, master cartons, palletization) align with destination market handling requirements.

What Are the Best Notebook Factory Suppliers?

| Company Name | Location | Production Focus | Monthly Output Capacity | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Dongguan Liyang Technology Co., Ltd. | Guangdong, CN | Premium customizable notebooks | ~800,000 units | 96% | ≤2h | US $140,000+ | 34% | 50 pcs |

| Shenzhen Jinlicai Printing Co., Ltd. | Shenzhen, CN | Custom journals & school supplies | ~600,000 units | 97% | ≤4h | US $70,000+ | 29% | 100 pcs |

| Hefei Skyfly Enterprise Co., Ltd. | Anhui, CN | High-volume exercise books | 2,000,000+ units | 100% | ≤3h | US $3,100,000+ | 100% | 100,000 pcs |

| Hefei Colorfly Stationery Co., Ltd. | Anhui, CN | Economy-grade stationery | 1,500,000+ units | 100% | ≤4h | US $6,200,000+ | 28% | 10,000–100,000 pcs |

| Sheng Kang Industrial (HK) Limited | Hong Kong | Promotional & office notebooks | ~400,000 units | 96% | ≤4h | US $30,000+ | <15% | 5 pcs |

Performance Analysis

Hefei-based manufacturers dominate high-volume production, with both Skyfly and Colorfly achieving 100% on-time delivery and multi-million-dollar annual revenues—indicative of robust operational systems. Skyfly stands out with a 100% reorder rate, suggesting exceptional product consistency for bulk commodity notebooks. In contrast, Dongguan and Shenzhen suppliers offer lower MOQs (as low as 50 pieces), faster response times, and broader customization, making them ideal for branded or promotional orders. Buyers seeking premium finishes should prioritize partners with foil stamping, embossing, and soft-touch lamination experience. For cost-sensitive contracts, Anhui factories provide optimal economies of scale, though minimum order thresholds may exclude small businesses.

FAQs

What are typical MOQs for custom notebook production?

MOQs vary significantly by factory type. Premium customization suppliers accept orders from 50–500 units, while high-efficiency producers require 10,000 to 100,000+ units for economic viability. Unit price decreases substantially beyond 50,000 pieces due to fixed setup cost amortization.

How long does custom notebook production take?

Standard lead time ranges from 12–20 days after sample approval. Complex designs involving multi-layer covers, embedded magnets, or special coatings may extend to 25 days. Express production (7–10 days) is occasionally available at a 20–30% premium.

Can suppliers provide free samples?

Most suppliers charge a nominal fee for initial samples (typically $10–$50), refundable upon order placement. Fully customized prototypes incur higher costs due to tooling and setup. Blank format samples are often provided free of charge.

What file formats are required for custom design submission?

Suppliers require vector artwork (AI, EPS, PDF) with bleed margins (3–5mm) and CMYK color mode. High-resolution raster files (300 dpi, PNG/TIF) are acceptable for photographic covers. Provide separate layers for front, back, and spine elements.

What logistics options are available for international shipping?

Sea freight is standard for containerized orders (FCL/LCL), with transit times of 18–35 days depending on destination. Air freight reduces delivery to 5–10 days but increases costs 3–5x. Most suppliers coordinate with forwarders and can deliver DDP (Delivered Duty Paid) upon request.