Notebooks Types

1/62

1/62

0

0

1/58

1/58

0

0

1/3

1/3

0

0

1/3

1/3

1/34

1/34

0

0

0

0

1/3

1/3

1/15

1/15

CN

CN

1/12

1/12

1/3

1/3

0

0

1/3

1/3

About notebooks types

Where to Find Notebooks Types Suppliers?

China leads global production of notebooks across multiple categories—including spiral, composition, softcover, hardcover, and specialty formats—supported by concentrated manufacturing hubs in Guangdong, Zhejiang, and Shanghai. These regions host vertically integrated paper goods clusters with access to raw materials such as wood-free paper, PP covers, and eco-friendly binding adhesives. Guangdong alone accounts for over 40% of China’s stationery exports, leveraging proximity to Hong Kong and Shenzhen ports for efficient international shipping.

Industrial zones in Wenzhou (Zhejiang) and Dongguan (Guangdong) specialize in high-volume notebook assembly, combining automated cutting, collating, and saddle-stitching lines with semi-automated perfect binding systems. This integration enables economies of scale, reducing unit costs by 15–25% compared to decentralized suppliers. Buyers benefit from consolidated ecosystems where paper mills, printing houses, lamination services, and packaging suppliers operate within 30km radii, supporting lead times as short as 15–20 days for standard bulk orders.

How to Choose Notebooks Types Suppliers?

Apply the following verification criteria when evaluating potential partners:

Quality Management Systems

Confirm ISO 9001 certification for standardized production processes. For markets requiring environmental compliance—such as the EU or North America—verify RoHS and FSC (Forest Stewardship Council) certifications to ensure sustainable sourcing and chemical safety in inks and coatings. Request test reports for paper brightness (minimum 85% ISO), grammage accuracy, and adhesive bond strength under humidity variations.

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum monthly output capacity of 500,000 units for consistent supply

- In-house capabilities including offset/digital printing, die-cutting, wire-o binding, and case-binding

- Dedicated quality control team conducting AQL 2.5 inspections per batch

Cross-reference factory size (recommended ≥3,000m²) with order fulfillment history to confirm scalability for seasonal demand surges.

Customization & Transaction Security

Require proof of design support via PDF mockups or physical samples before mass production. Ensure suppliers accept third-party inspections (e.g., SGS, Bureau Veritas) at final random check (FRC) stage. Use secure payment terms such as 30% advance + 70% against bill of lading copy, or escrow-based arrangements for first-time transactions. Retain sample batches for 90 days post-delivery to assess long-term durability and print retention.

What Are the Best Notebooks Types Suppliers?

No supplier data is currently available for analysis. Procurement teams are advised to initiate RFQs through verified B2B channels, prioritizing manufacturers with documented export experience to Europe, North America, or Japan. Focus on suppliers demonstrating full traceability—from pulp sourcing to finished product—and those offering digital catalog access with SKU-level specifications.

Performance Analysis

In absence of specific supplier profiles, sourcing strategy should emphasize audit readiness and process transparency. Prioritize vendors who provide facility videos, machine lists, and staff qualification records. High-performing notebook suppliers typically maintain reorder rates above 40%, supported by stable pricing (±5% annually), sub-24-hour response times, and MOQ flexibility (ideally ≤1,000 units per SKU). For customized notebooks (e.g., branded corporate editions), verify prepress workflow efficiency—top-tier suppliers deliver print-ready proofs within 48 hours.

FAQs

How to verify notebook supplier reliability?

Validate business licenses and cross-check export records via customs databases. Request references from existing clients in your target market. Conduct virtual or on-site audits focusing on inventory management, waste control, and packaging standards. Analyze customer feedback related to color consistency, page alignment, and cover warping after transit.

What is the average sampling timeline?

Standard samples take 5–7 days to produce, while custom designs with logo printing or unique binding require 10–14 days. Add 3–6 days for international express delivery. Some suppliers offer digital sampling (high-resolution renders) within 48 hours for initial approval.

Can suppliers ship notebooks worldwide?

Yes, most established manufacturers handle global logistics via sea, air, or rail. Confirm Incoterms (FOB, CIF, DDP) during negotiation. Sea freight is optimal for full container loads (e.g., 20ft container ≈ 200,000–300,000 units depending on type), while air freight suits urgent small-batch deliveries.

Do manufacturers provide free samples?

Commonly, 1–3 free samples are offered for evaluation; however, buyers usually cover shipping costs. Free samples are more likely when projected annual volume exceeds 100,000 units. Customized samples may incur a nominal fee, refundable upon order confirmation.

How to initiate customization requests?

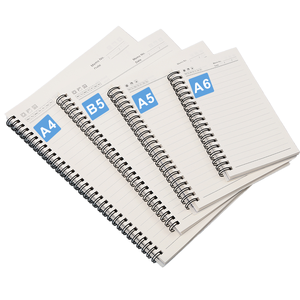

Submit detailed specifications including dimensions (A4, A5, etc.), page count, paper weight (e.g., 70gsm, 100gsm), cover material (PP, PU leather, cardboard), binding type (spiral, glue, sewn), and artwork files (in CMYK/Pantone format). Leading suppliers respond with technical drawings and cost breakdowns within 72 hours.