Ntc Temperature Sensor Distributor

About ntc temperature sensor distributor

Where to Find NTC Temperature Sensor Distributors?

China remains the central hub for NTC temperature sensor manufacturing and distribution, with key production clusters in Guangdong and Huizhou offering integrated supply chains and specialized electronics expertise. These regions host vertically aligned facilities capable of handling full-cycle production—from thermistor element fabrication to encapsulated probe assembly—enabling rapid scalability and cost efficiency. Dongguan and Huizhou, in particular, have developed mature ecosystems where component sourcing, molding, calibration, and packaging operations are concentrated within compact industrial zones, reducing logistics overhead and accelerating fulfillment cycles.

Suppliers in this region benefit from proximity to semiconductor material suppliers and electronic testing infrastructure, supporting consistent quality control across high-volume batches. The localized ecosystem enables MOQ flexibility, with some manufacturers accommodating orders as low as 10 pieces for customized configurations. Average lead times range from 7–15 days for standard models, while custom designs typically require 20–30 days depending on technical complexity. This operational density supports 20–35% lower unit costs compared to equivalent suppliers outside Asia, making the region a strategic sourcing destination for global distributors and OEMs.

How to Choose NTC Temperature Sensor Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Product Range

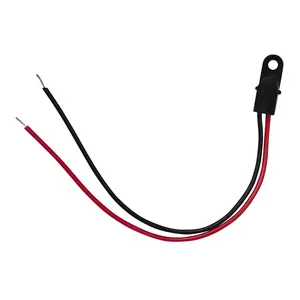

Assess whether suppliers offer required resistance values (e.g., 5K, 10K, 50K, 100K Ω), B-values (e.g., 3950K), and form factors such as epoxy-coated beads, copper tube probes, or surface-mount chips. Verify availability of customization options including cable length, insulation material (PVC, Teflon, fiberglass), and connector types. Fast response time and stability over operating ranges (-40°C to +150°C typical) should be documented in product datasheets.

Quality Assurance and Compliance

Prioritize suppliers adhering to internationally recognized quality standards. While formal ISO 9001 certification is not explicitly stated in available data, consistent on-time delivery performance (≥100%) among top-tier suppliers indicates robust internal processes. Look for evidence of RoHS compliance and batch-level testing protocols for resistance accuracy and thermal cycling endurance. Request test reports for long-term drift characteristics and interchangeability tolerances when deploying sensors in precision applications.

Production Capacity and Responsiveness

Evaluate operational scale through proxy indicators such as online revenue volume and response time. Leading suppliers report annual online revenues exceeding US $60,000, with response times under 1 hour, suggesting dedicated sales engineering support. Minimum order quantities vary significantly—from 100 to 1,000 pieces—indicating differing production models: smaller MOQs often correlate with prototyping agility, while higher MOQs align with automated bulk manufacturing.

Transaction Reliability

Analyze reorder rates as a proxy for customer satisfaction; all listed suppliers report reorder rates below 15%, which may reflect market competitiveness rather than poor performance. Cross-reference on-time delivery records—where available—with sample pricing structures to assess value consistency. For initial procurement, start with small-batch trials to validate dimensional accuracy, electrical performance, and packaging integrity before scaling.

What Are the Top NTC Temperature Sensor Distributors?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Dongguan City Heng Hao Electric Co., Ltd. | Temperature Sensors, Switches, Resistors | $0.14/unit | 1,000 pcs | 100% | ≤3h | US $4,000+ | <15% |

| Dongguan Shengruichi Electronic Co., Ltd. | Temperature Sensors, Fuses, Circuit Breakers | $0.15–4.23/unit | 100–1,000 pcs | 100% | ≤1h | US $60,000+ | <15% |

| Huizhou Huakaiwei Electronic Sci&tech Co., Ltd. | Temperature Sensors, Magnetic Sensors, Switches | $0.13–0.20/unit | 100–1,000 pcs | 72% | ≤11h | US $30,000+ | <15% |

| Guangdong Guande Sensing Technology Co.,Ltd | Temperature Sensors, Thermistors, PCBA | $0.35–3.00/unit | 10–500 pcs | 100% | ≤6h | US $400+ | <15% |

| Fast Sensor Hongkong Limited | Flow Sensors, Level Sensors, Proximity Sensors | $0.30–7.00/unit | 1–50 pcs | 71% | ≤5h | US $2,000+ | <15% |

Performance Analysis

Dongguan Shengruichi stands out with the highest reported online revenue (US $60,000+) and fastest average response time (≤1 hour), combined with 100% on-time delivery, indicating strong operational discipline and customer service infrastructure. Dongguan Heng Hao offers competitive pricing at $0.14 per unit with scalable output validated by reliable fulfillment metrics. In contrast, Huizhou Huakaiwei and Fast Sensor Hongkong report sub-75% on-time delivery rates, suggesting potential bottlenecks in logistics or production planning despite offering low MOQs and broad product variety.

Guangdong Guande differentiates itself with ultra-low minimum orders (as few as 10 pieces), catering effectively to R&D teams and low-volume integrators. However, its limited revenue footprint suggests niche positioning. Buyers seeking high-volume consistency should prioritize suppliers with 100% on-time delivery records and response times under 6 hours. For prototype development or multi-parameter validation, suppliers offering mixed-value kits (5K, 10K, 100K) and flexible cabling options provide greater testing agility.

FAQs

What is the typical MOQ for NTC temperature sensors?

MOQs range from 10 to 1,000 pieces depending on model and supplier. High-volume producers typically require 1,000-piece minimums, while specialized or custom sensor providers may accept orders as low as 10–100 pieces, particularly for pre-production sampling.

How are NTC sensors tested before shipment?

Reputable suppliers conduct batch resistance measurements at reference temperatures (e.g., 25°C) and perform spot checks at extreme points (e.g., 0°C, 85°C). Some offer interpolation curves and Beta value verification upon request. Independent lab validation is recommended for mission-critical deployments.

Can suppliers customize NTC sensor configurations?

Yes, multiple suppliers list customizable options including probe length, sheath material (copper, stainless steel), insulation type, and connector style. Customization lead time typically adds 5–10 days to standard production schedules.

Do NTC sensor distributors provide technical documentation?

Most suppliers provide basic datasheets listing resistance-temperature tables, B-values, and physical dimensions. Advanced documentation such as IEC 60751 compliance reports or calibration certificates may require direct inquiry and could incur additional fees.

What are common applications for these NTC sensors?

These sensors are widely used in HVAC systems, refrigeration units, power supplies, battery management systems, and industrial automation equipment where accurate temperature monitoring is critical. Epoxy-coated variants suit general-purpose use, while metal-sheathed probes are designed for rugged environments.