Nut Tapping Machine Price In India

Top sponsor listing

Top sponsor listing

CN

CN

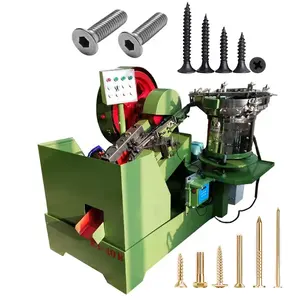

About nut tapping machine price in india

Where to Find Nut Tapping Machine Suppliers?

China remains the dominant global source for nut tapping machines, with specialized manufacturing clusters in Guangdong, Hebei, Zhejiang, and Henan provinces. These regions host vertically integrated facilities capable of producing both standard and custom threading solutions for hex nuts, flange nuts, and precision fasteners. Dongguan and Ningbo serve as key hubs for automated tapping systems, offering streamlined access to component suppliers and export logistics networks.

The industrial ecosystems in these zones support end-to-end production—from CNC machining and thread rolling to final assembly—enabling rapid prototyping and scalable order fulfillment. Suppliers typically operate under lean manufacturing principles, achieving lead times of 20–45 days for standard configurations. Localization of supply chains reduces material costs by 15–25% compared to equivalent Western production, while maintaining compatibility with international quality benchmarks. Buyers benefit from flexible MOQs ranging from single units to container-scale orders, particularly for semi-automatic and multi-spindle models tailored to high-volume fastener production lines.

How to Choose Nut Tapping Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to recognized quality management standards such as ISO 9001. For export markets, confirm CE marking or compliance with regional safety directives (e.g., EU Machinery Directive). Request documentation on motor specifications, spindle accuracy (±0.02mm tolerance), and cycle time performance. Machines designed for M3–M12 threading should demonstrate repeatability over 10,000+ cycles without tool degradation.

Production Capability Verification

Assess core manufacturing competencies through the following indicators:

- Facility size exceeding 2,000m² indicating volume capacity

- In-house engineering teams supporting customization (e.g., servo-driven arms, PLC controls)

- Integrated testing protocols for vibration resistance, thermal stability, and electrical safety

Cross-reference on-time delivery rates (target ≥96%) and response times (ideally ≤5 hours) as proxies for operational reliability.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align payment milestones with shipment and inspection. Prioritize suppliers with verifiable reorder rates below 20%, indicating consistent customer satisfaction. Conduct pre-shipment inspections or request factory-produced video demonstrations of machine operation under load conditions. Sample testing is recommended to validate threading precision and integration compatibility with existing production lines.

What Are the Best Nut Tapping Machine Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Notable Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Dongguan Thor Machinery Co., Ltd. | Drilling Machines, Grinding Machines, Chamfering Machines | 96% | ≤3h | <15% | $80,000+ | Multi-functional tapping and drilling systems | N/A |

| Baoding Xiaoguo Intelligent Equipment Co., Ltd. | Metal Casting & Forging Machinery, Thread Rolling Machines | 100% | ≤15h | – | – | Full-automatic 4–14 spindle nut tap machines | $4,000–13,000 |

| Ningbo Bysen Machinery Co., Ltd. | Metal Forging, Thread Rolling, Drilling Machines | 100% | ≤5h | <15% | $90,000+ | Custom-made automatic nut tapping machines | $2,800–5,200 |

| Henan Demma CNC Equipment Co., Ltd. | CNC Threading, Drilling & Tapping Systems | 100% | ≤1h | 20% | $140,000+ | Universal servo-driven tapping units (M3–M12) | $379–3,800 |

| Xuchang Huarui Machinery Co., Ltd. | Nut Making Lines, Cold Forging Machines | 100% | ≤5h | 100% | $50,000+ | High-efficiency automatic nut threading systems | $3,000–28,500 |

Performance Analysis

Baoding Xiaoguo and Xuchang Huarui specialize in high-capacity, multi-station automation ideal for industrial fastener manufacturers requiring throughput above 3,000 pieces per hour. Ningbo Bysen offers competitively priced entry-level automation with strong delivery consistency. Henan Demma stands out for responsiveness (≤1h average reply) and cost-effective benchtop models suitable for SMEs and maintenance workshops. Notably, Xuchang Huarui’s 100% reorder rate suggests exceptional post-sale support and machine durability despite higher price points. Suppliers with documented online revenue exceeding $90,000 demonstrate sustained market presence and service maturity.

FAQs

What is the typical MOQ for nut tapping machines?

Most suppliers offer a minimum order quantity of 1 set or piece, especially for automated and semi-automatic models. Bulk pricing applies at 5+ units, though some manufacturers accommodate trial orders for new buyers.

How long does it take to fulfill an order?

Standard lead time ranges from 20 to 40 days after deposit confirmation. Customized models with specific voltage (220V/380V), PLC interfaces, or special tooling may extend delivery by 10–15 days.

Can nut tapping machines be customized?

Yes, leading suppliers support modifications including spindle count (4–14 heads), feeding mechanisms (vibratory bowl, conveyor), and control systems (servo, pneumatic). Provide technical drawings or sample parts for accurate quoting.

Do suppliers provide installation and training?

Many offer remote setup guidance via video call. On-site commissioning is available upon request but may incur additional travel charges. User manuals and wiring diagrams are typically provided in English.

Are spare parts included?

Basic tooling kits and wear components (e.g., taps, collets) are often bundled. Long-term supply agreements for consumables can be negotiated during procurement.