Offset Printing Machine Suppliers

1/15

1/15

1/10

1/10

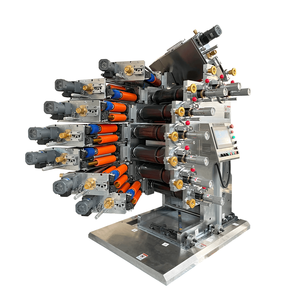

About offset printing machine suppliers

Where to Find Offset Printing Machine Suppliers?

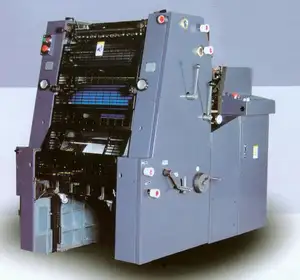

China remains the global hub for offset printing machine manufacturing, with key supplier clusters concentrated in Shandong and Guangdong provinces. These regions host vertically integrated production ecosystems that combine precision engineering, component sourcing, and final assembly within compact industrial zones. Shandong, particularly Weifang, is recognized for its specialization in both new and refurbished sheet-fed offset presses, supported by a mature network of technical service providers and spare parts manufacturers. Guangdong’s Shenzhen and Guangzhou areas focus on high-end used machinery imports and reconditioning, offering buyers access to German-engineered Heidelberg, Man Roland, and Komori systems at competitive price points.

The clustering effect enables suppliers to maintain lean operations with reduced logistics overhead and faster turnaround times. Facilities typically operate under ISO-aligned quality frameworks and offer lead times ranging from 15 to 45 days depending on equipment condition and customization requirements. Buyers benefit from flexible procurement models, including direct factory sales, third-party inspections, and global shipping arrangements. The availability of both entry-level small-format machines and large multi-color presses supports diverse market needs—from regional print shops to industrial-scale packaging producers.

How to Choose Offset Printing Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Verification

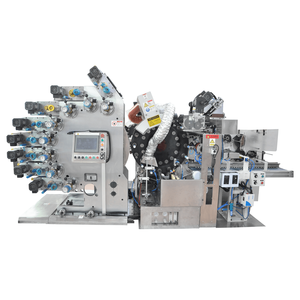

Confirm machine specifications match production requirements, including printing format (e.g., B2, B1), color stations (2–6 units), automation level (manual vs. automatic feeding), and compatibility with substrate types. For used equipment, request detailed maintenance logs, refurbishment records, and operational hours. CE marking or equivalent safety certification should be present for compliance in regulated markets.

Production and Reconditioning Capability

Assess supplier infrastructure through available indicators:

- Proven experience in disassembly, cleaning, mechanical adjustment, and electrical system upgrades

- In-house testing protocols for registration accuracy, ink distribution, and pneumatic systems

- Access to OEM-equivalent spare parts and technical documentation

Cross-reference response time metrics (target ≤5 hours) and on-time delivery rates (ideally >90%) as proxies for operational reliability.

Transaction Security & After-Sales Support

Prioritize suppliers offering inspection rights prior to shipment and escrow-based payment terms. Evaluate after-sales capability—especially critical for used machinery—including remote diagnostics, technician dispatch, and training services. Analyze reorder rates as an indicator of customer satisfaction; rates exceeding 30% suggest consistent performance and support quality.

What Are the Best Offset Printing Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range Focus | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Weifang Mingzhu Electronic Technology Co., Ltd. | Weifang, CN | Offset Printers, Printing Machinery Parts | US $30,000+ | 93% | ≤5h | 35% | Used SM/CD Series (Heidelberg) | $28,000–$110,900 |

| Weifang Swan Machinery Co., Ltd. | Weifang, CN | Offset Printers, Post-Press Equipment | US $270,000+ | 100% | ≤9h | <15% | New GTO Models & Entry-Level Presses | $1,000–$23,800 |

| Guangzhou Xinsheng Printing Machinery Parts Limited | Guangzhou, CN | Offset Printers, Machinery Parts | US $10,000+ | 100% | ≤3h | 33% | Used GTO52, Man Roland Components | $5,500–$22,500 |

| Shenzhen Yongyu Printing Machinery Co., Ltd. | Shenzhen, CN | Offset Printers, Paper Processing Machinery | US $1,000,000+ | 91% | ≤4h | 33% | Premium Used Heidelberg/Komori Lines | $24,500–$113,000 |

| Weifang Taurus Trade Co., Ltd. | Weifang, CN | Offset Printers, Flexographic Machines | US $80,000+ | 100% | ≤2h | <15% | New Mini-Offset & 2–4 Color Systems | $2,400–$35,000 |

Performance Analysis

Suppliers like Shenzhen Yongyu and Weifang Mingzhu specialize in high-value used European presses, catering to mid-to-large print houses requiring proven reliability. Their higher price bands reflect comprehensive reconditioning and alignment with industrial-grade output standards. In contrast, Weifang Taurus and Weifang Swan target budget-conscious buyers and startups with new mini-offset and entry-level GTO models, enabling low MOQs and rapid deployment. Guangzhou Xinsheng stands out for component-level support and quick response times, ideal for maintenance-driven procurement. Notably, all top-tier suppliers maintain on-time delivery rates above 90%, while Weifang-based firms demonstrate superior responsiveness, with two achieving sub-5-hour average reply times. Reorder rates above 30% indicate strong post-sale service alignment, particularly among specialists handling complex machinery.

FAQs

How to verify offset printing machine supplier reliability?

Validate operational history, request references from past international clients, and review machine inspection reports from independent third parties. Confirm whether the supplier conducts load tests and color registration calibration before shipment. Check for consistency in product descriptions, pricing logic, and technical documentation across listings.

What is the typical lead time for offset press delivery?

For ready-to-ship units, lead time ranges from 15 to 30 days after payment confirmation. Custom refurbishments or configuration changes may extend timelines to 45–60 days. Air freight is rarely used due to size and weight; sea freight (FCL/LCL) is standard, adding 20–40 days depending on destination port.

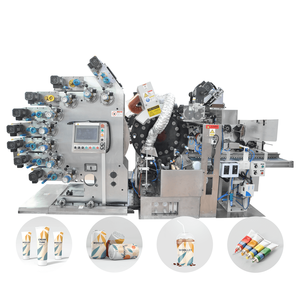

Do suppliers offer customization or retrofitting services?

Yes, many suppliers provide control system upgrades (e.g., PLC modernization), feeder/auctioneer adjustments, and integration with prepress workflows. Retrofitting drying systems or adding inline inspection cameras is feasible but must be specified prior to purchase. Confirm technical capacity through engineering team verification or facility videos.

Can I request a sample run or test print?

Some suppliers offer digital print simulations or video demonstrations of live operation. Physical sample runs are possible but incur additional handling and shipping costs. Buyers should define substrate type, ink coverage, and tolerance levels (e.g., ±0.1mm registration) when arranging evaluations.

What are common payment and shipping terms?

Standard terms include 30% advance payment with balance before shipment, often secured via trade assurance or letter of credit. FOB terms are prevalent, though CIF can be arranged. Buyers are responsible for import duties, local customs clearance, and final installation. Insurance coverage during transit is strongly recommended given equipment value.