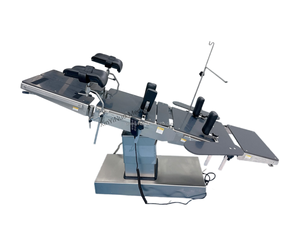

Operating Table

Top sponsor listing

Top sponsor listing

1/43

1/43

1/23

1/23

1/24

1/24

1/20

1/20

1/29

1/29

1/17

1/17

1/25

1/25

1/24

1/24

1/31

1/31

About operating table

Where to Find Operating Table Suppliers?

China remains the global epicenter for medical operating table manufacturing, with key production clusters in Jiangsu, Shandong, and Guangdong provinces. These regions host vertically integrated facilities that combine precision engineering, advanced hydraulics, and medical-grade material processing. Jiangsu’s Yancheng and Xuzhou zones are home to over 40% of China’s certified medical device manufacturers, offering streamlined access to stainless steel fabrication, CNC machining, and sterilization-compatible surface treatments. Shandong’s Zibo and Linyi districts specialize in electric-hydraulic surgical systems, leveraging proximity to industrial automation suppliers to reduce component lead times by up to 25%.

The regional ecosystems support rapid prototyping and scalable production, with many suppliers operating end-to-end workflows—from structural frame welding to motorized actuator integration—within single campuses. Buyers benefit from consolidated logistics, with average production cycles ranging from 15–30 days for standard models. Cost efficiencies are notable: localized supply chains for aluminum alloys, polyurethane padding, and medical-grade polymers contribute to 20–35% lower unit costs compared to EU- or U.S.-based producers. The clusters also facilitate customization, with digital design teams supporting CAD-based modifications for specialized surgical applications.

How to Choose Operating Table Suppliers?

Procurement decisions should be guided by systematic evaluation of technical, operational, and transactional criteria:

Quality & Compliance Verification

Confirm ISO 13485 certification as a baseline for medical device manufacturing. For export to regulated markets (EU, North America), CE marking and FDA registration are essential for customs clearance and clinical deployment. Request documentation on biocompatibility testing (ISO 10993) and electrical safety compliance (IEC 60601-1) for motorized models. Review sterilization validation reports if tables are intended for sterile environments.

Production & Engineering Capacity

Assess supplier infrastructure using these benchmarks:

- Minimum 3,000m² dedicated manufacturing area for consistent output

- In-house R&D teams capable of generating technical drawings and 3D renderings within 72 hours

- Integrated capabilities in hydraulic/pneumatic system assembly, powder coating, and electronic control panel integration

Cross-reference facility size with order fulfillment metrics—suppliers with >95% on-time delivery typically maintain buffer inventory and dual-shift operations.

Customization & Transaction Security

Prioritize suppliers offering documented customization options for table dimensions, load capacity (typically 135–250kg), Trendelenburg angles, and accessory rails. Verify packaging standards (wooden crates with moisture barriers) for international shipping. Utilize secure payment mechanisms such as escrow services, and request post-delivery inspection clauses. Pre-shipment verification via third-party audits (e.g., SGS) is recommended for orders exceeding 10 units.

What Are the Best Operating Table Suppliers?

| Company Name | Location | Supplier Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Product Range |

|---|---|---|---|---|---|---|---|---|

| Jiangsu Rooe Medical Technology Co., Ltd. | Jiangsu, CN | Multispecialty Supplier | US $330,000+ | 100% | ≤2h | <15% | Color, material, size, logo, packaging, plug, label, graphic | Hospital Beds, Sterilization Equipment, Funeral Supplies |

| Jiangsu Suxin Medical Equipment Co., Ltd. | Jiangsu, CN | Custom Manufacturer | US $110,000+ | 100% | ≤1h | <15% | Hydraulic, color, material, size, drawing, logo, model, packaging, label, graphic | Manual, Electric, Ophthalmic, Examination Tables |

| Shandong Xinda Medical Equipment Co., Ltd. | Shandong, CN | Custom Manufacturer | US $200,000+ | 100% | ≤1h | 19% | Color, material, size, logo, packaging, label, graphic | Electric, Multi-Purpose, Ophthalmic Surgical Tables |

| Guangzhou Howell Medical Devices Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $190,000+ | 96% | ≤2h | 35% | Color, material, size, logo, packaging, label, graphic | High-End Electric-Hydraulic, Rotating, Ultra-Low Models |

| Jiaxing Greatmicro Medical Equipment Co., Ltd. | Zhejiang, CN | General Supplier | US $20,000+ | 90% | ≤4h | 15% | Limited customization | Manual, Electric-Hydraulic, Multifunctional Tables |

Performance Analysis

Jiangsu- and Shandong-based suppliers demonstrate superior reliability, with 100% on-time delivery rates and sub-2-hour response times. Jiangsu Suxin and Shandong Xinda stand out for engineering flexibility, offering hydraulic system modifications and CAD-based design adjustments. Guangzhou Howell targets premium segments with high-cost electric-hydraulic models ($7,000–$14,800), though its 96% delivery rate and 35% reorder rate suggest potential fulfillment volatility. Jiaxing Greatmicro, while cost-competitive (tables from $380), shows slower responsiveness and limited customization depth. Buyers seeking regulatory-compliant, scalable supply should prioritize ISO-certified custom manufacturers with proven export histories and structured quality management systems.

FAQs

How to verify operating table supplier credibility?

Cross-validate certifications (ISO 13485, CE) through official registries. Request factory audit reports or video tours confirming in-house production. Analyze customer reviews focusing on after-sales service, product durability, and compliance documentation accuracy.

What is the typical MOQ and lead time?

Most suppliers offer MOQs of 1 set, enabling sample procurement. Standard lead times range from 15–25 days for manual tables and 25–35 days for electric-hydraulic models. Bulk orders (10+ units) may require additional time for quality batch testing.

Can suppliers customize operating tables for specific surgeries?

Yes, leading manufacturers support application-specific designs—including ophthalmic, urological, and orthopedic configurations—with adjustable sections, rail mounts, and imaging compatibility. Submit detailed technical requirements, including weight distribution, tilt ranges, and sterility protocols.

Do suppliers provide pre-shipment inspection options?

Reputable suppliers allow third-party inspections (e.g., SGS, BV) before shipment. Confirm inspection clauses in contracts and allocate time in procurement timelines—typically 3–5 business days for on-site verification.

What materials are commonly used in operating tables?

Frames are typically constructed from medical-grade stainless steel or lightweight aluminum alloys. Surfaces use radiolucent carbon fiber or PU-coated padding for patient comfort and imaging compatibility. Seams are sealed to meet hospital infection control standards.