Pallet Machine Maker

CN

CN

CN

CN

CN

CN

About pallet machine maker

Where to Find Pallet Machine Maker Suppliers?

China remains the central hub for pallet machine manufacturing, with key production clusters concentrated in Henan and Shandong provinces. These regions host vertically integrated facilities capable of producing complete automated lines—from raw material processing to final assembly—enabling competitive pricing and scalable output. Zhengzhou (Henan) specializes in cost-efficient, modular systems for wooden pallet production, while Qingdao (Shandong) focuses on high-capacity, fully automatic lines designed for industrial-scale operations.

The ecosystem benefits from localized supply chains for motors, conveyors, nailers, and control systems, reducing component lead times by 20–30% compared to offshore alternatives. Suppliers in these zones typically operate under lean manufacturing principles, achieving standard delivery windows of 30–60 days for custom-built machinery. Buyers gain access to flexible configurations, including EPAL/EUR-standard compliance, nailing vs. stapling mechanisms, and integration with upstream sawmills or downstream packaging systems.

How to Choose Pallet Machine Maker Suppliers?

Adopt a structured evaluation framework when selecting suppliers:

Technical Capability Assessment

Confirm whether the supplier designs and assembles core components in-house, particularly frame structures, conveyor systems, and pneumatic nailing units. Prioritize manufacturers offering CE certification for electrical controls and mechanical safety. For export markets, verify compatibility with local voltage standards (e.g., 380V/50Hz vs. 480V/60Hz).

Production Infrastructure Review

Evaluate operational scale through objective indicators:

- Minimum factory area exceeding 3,000m² for full-line production capacity

- In-house engineering team supporting customization (e.g., layout design, PLC programming)

- On-site testing protocols for cycle time, load tolerance, and failure rate

Cross-reference declared capabilities with on-time delivery performance (target ≥97%) and reorder rates as proxies for reliability and customer satisfaction.

Procurement Risk Mitigation

Utilize secure transaction methods such as escrow payment systems until post-delivery commissioning is completed. Request video demonstrations of machine operation under real-load conditions. Insist on detailed technical documentation, including wiring diagrams, maintenance manuals, and spare parts lists. Pre-shipment inspections by third-party agencies (e.g., SGS, BV) are recommended for orders above $50,000.

What Are the Best Pallet Machine Maker Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Leabon Machinery Equipment Co., Ltd. | Henan, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100.0% | ≤2h | Verified Supplier | 50%-100% |

| Qingdao Saifan Packaging Machinery Manufacturing Co., Ltd. | Shandong, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100.0% | ≤2h | No Public Rating | Not Available |

| Zouping Artson Machinery Limited | Shandong, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100.0% | ≤3h | Verified Supplier | <15% |

| Bremetz (Shandong) Machinery Co., Ltd. | Shandong, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100.0% | ≤4h | No Public Rating | Not Available |

Performance Analysis

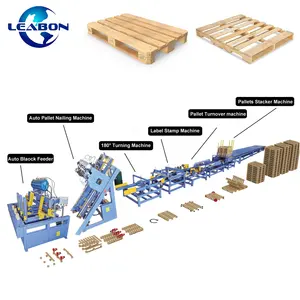

Zhengzhou Leabon stands out with dual verification markers: consistent on-time delivery, a 100% fulfillment record, and a high reorder rate (50–100%), indicating strong post-sale performance and client retention. The company offers mid-range automated systems priced between $10,000–$20,000, suitable for small to medium producers. Qingdao Saifan targets large-scale operators with turnkey production lines exceeding $300,000, reflecting specialization in high-throughput, fully integrated systems. Zouping Artson provides entry-level automation at competitive price points ($4,500–$25,000), though its low reorder rate suggests limited repeat business. Bremetz (Shandong) focuses on column-type palletizers for bagged goods, indicating niche expertise outside traditional wooden pallet fabrication. Buyers seeking standardized solutions should prioritize suppliers with documented customization options and proven export experience.

FAQs

How to verify pallet machine maker reliability?

Validate certifications (CE, ISO 9001) through official registries. Request references from existing clients in your region. Analyze response consistency, technical depth in communication, and availability of multilingual support. Confirm presence of after-sales service agreements and remote troubleshooting capabilities.

What is the typical MOQ and lead time?

Standard minimum order quantity is 1 set for most models. Lead times range from 30 days for semi-automatic machines to 60 days for fully customized production lines. Some suppliers offer expedited builds for urgent requirements at a premium.

Can suppliers customize pallet machines?

Yes, most established manufacturers support customization in dimensions, power configuration, control interface (PLC/HMI), and integration with existing conveyor networks. Common modifications include adjustable pallet size ranges (e.g., 800x1200mm to 1000x1200mm) and material-specific handling (softwood/hardwood).

Do suppliers provide installation and training?

Many offer remote setup guidance via video call. On-site commissioning and operator training may be available at additional cost, particularly for complex systems. Clarify service scope and travel expenses during negotiation.

What are common payment terms?

Standard terms include 30% advance payment and 70% before shipment. Letters of credit (L/C) and Trade Assurance-backed transactions are accepted by major suppliers to mitigate financial risk.