Palletizing Robot

Top sponsor listing

Top sponsor listing

1/12

1/12

1/25

1/25

1/3

1/3

1/3

1/3

1/20

1/20

1/20

1/20

1/7

1/7

1/3

1/3

CN

CN

1/24

1/24

CN

CN

CN

CN

1/19

1/19

1/25

1/25

CN

CN

1/8

1/8

1/3

1/3

1/12

1/12

1/3

1/3

About palletizing robot

Where to Find Palletizing Robot Suppliers?

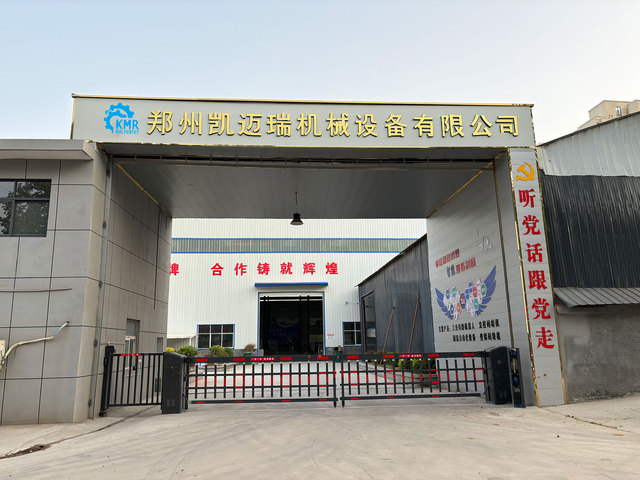

China remains a dominant force in the global palletizing robot manufacturing sector, with key industrial hubs concentrated in Shandong, Qingdao, and Henan provinces. These regions host vertically integrated supply chains that support rapid prototyping and large-scale production of robotic automation systems. Shandong and Qingdao specialize in industrial-grade robotic arms integrated with conveyor and strapping systems, leveraging proximity to steel and electronics suppliers to reduce component costs by 15–25%. Henan has emerged as a center for cost-effective, small-to-mid-range collaborative robots (cobots), catering to SMEs seeking automation with lower capital investment.

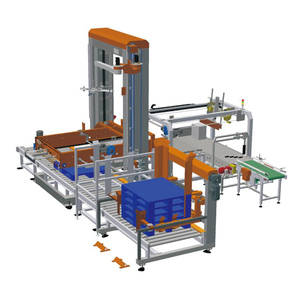

The clustering of engineering talent, material handling specialists, and CNC fabrication facilities within these zones enables streamlined development cycles. Suppliers typically operate from facilities exceeding 5,000m², supporting end-to-end production—from robotic arm assembly to full packaging line integration. Buyers benefit from lead times averaging 30–45 days for standard units and access to modular designs adaptable to diverse payload (25–50kg), cycle speed, and pallet configuration requirements. Customization is widely supported, including gripper types, labeling systems, CAD-based layout planning, and integration with existing warehouse management systems.

How to Choose Palletizing Robot Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Design Capabilities

Confirm availability of customization options such as robotic arm reach, payload capacity (up to 50kg), gripper design (for bags, cartons, or granular packaging), and integration with conveyors, strapping machines, or pallet dispensers. Request CAD drawings, 3D layouts, and engineering specifications prior to order placement. Suppliers offering comprehensive design input—such as Zaozhuang Fuliang Packaging Machinery Co., Ltd. and Qingdao Ausense Packing Equipment Co., Ltd.—demonstrate stronger engineering support.

Production & Quality Assurance

Evaluate suppliers based on verifiable performance metrics:

- On-time delivery rate ≥97%

- Average response time ≤2 hours

- Reorder rate >15% indicating customer retention

- Evidence of quality management systems (e.g., ISO 9001 implied through consistent delivery performance)

Cross-reference online revenue data where available—suppliers like Qingdao Ausense (US $1.2M+ annual online revenue) and Shandong Rayman (US $810K+) demonstrate market validation and scalability. Prioritize manufacturers with in-house CNC, welding, or robotic calibration capabilities, as indicated by customization tags related to laser/plasma cutting or structural engineering.

Transaction Security & Support

Favor suppliers with transparent pricing structures, clear minimum order quantities (typically 1 set), and documented after-sales service policies. Use secure payment mechanisms and request pre-shipment inspection rights. Analyze product listings for consistency in technical detail—high-detail entries often reflect better documentation and post-installation support readiness.

What Are the Best Palletizing Robot Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Notable Features |

|---|---|---|---|---|---|---|---|

| Qingdao Ausense Packing Equipment Co., Ltd. | Packaging Line, Wrapping Machines, Conveyors, Palletizers | 97% | ≤2h | 22% | US $1.2M+ | Yes | High reorder rate; broad system integration; extensive customization (material, size, label, layout) |

| Shandong Rayman Cnc Equipment Co., Ltd. | Collaborative Robots, Palletizing Systems | 94% | ≤2h | 19% | US $810K+ | Yes | Mid-range cobot solutions; gripper and logo customization; plasma/laser cutting integration |

| Zaozhuang Fuliang Packaging Machinery Co., Ltd. | Industrial Robots, Single-Column Palletizers, Granular Packaging Systems | 100% | ≤1h | <15% | US $70K+ | Yes | Fastest response; full engineering support; specialized in bag and granular product handling |

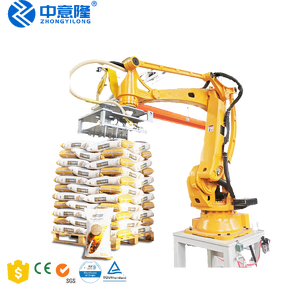

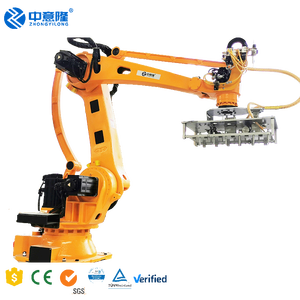

| Henan Zhong Yi Long Machinery Equipment Co., Ltd. | Automatic Cobot Palletizers, Small-Scale Robotic Stackers | 100% | ≤1h | <15% | US $110K+ | Yes | Cost-efficient models from $500; compact designs for limited-space operations |

| Shanghai Junqi Machinery Co., Ltd. | High-Speed Bag Palletizers, Multi-Function Packaging Lines | 100% | ≤1h | - | - | Limited | Highest-capacity systems (up to $120K); suited for high-volume valve bag operations |

Performance Analysis

Qingdao Ausense stands out for its strong reorder rate (22%) and comprehensive system integration, making it ideal for buyers requiring turnkey packaging lines. Shandong Rayman offers competitive pricing ($5,300–$7,000 range) and cobot-focused innovation, suitable for automated but space-constrained environments. Zaozhuang Fuliang and Henan Zhong Yi Long both achieve 100% on-time delivery with sub-1-hour response times, reflecting operational efficiency despite lower reorder rates—potentially due to project-specific sales rather than repeat contracts. Shanghai Junqi targets high-throughput applications, with premium systems priced up to $120,000, though limited transaction visibility suggests niche market positioning.

FAQs

What is the typical MOQ and pricing for palletizing robots?

Minimum order quantity is generally 1 set. Entry-level economic models start at $500–$900, while fully automatic industrial systems range from $7,500 to $13,000. High-speed, heavy-duty configurations can exceed $120,000 depending on throughput and integration complexity.

How long does it take to fulfill an order?

Standard lead time ranges from 30 to 45 days after design confirmation. Custom engineering projects may extend this to 60 days, particularly if CAD layout approval, safety certification, or third-party testing is required.

Can suppliers customize palletizing robots for specific packaging formats?

Yes, most suppliers offer customization for carton, bag, valve sack, and granular product handling. Modifications include gripper type, pallet dispenser integration, labeling systems, strapping compatibility, and robotic arm reach/payload adjustments. Engineering drawings and layout simulations are commonly provided upon request.

Do these suppliers support international shipping and compliance?

Most manufacturers export globally and comply with common industrial safety standards. While explicit CE or ISO certifications are not listed, consistent on-time delivery and structured product documentation suggest adherence to baseline quality practices. Buyers should confirm voltage, control panel language, and mechanical safety guards meet destination-country regulations prior to shipment.

Is sample testing available before bulk procurement?

Sample availability varies. Some suppliers offer functional demos or video validations of operating units. For physical samples, expect partial cost recovery policies, especially for high-value robotic systems. Prototypes with customized features typically require 3–4 weeks for development and testing.