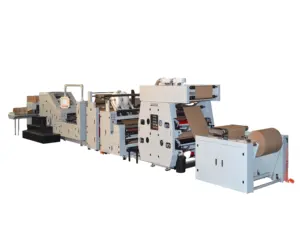

Paper Bag Making Machine With Printing Price In India

Top sponsor listing

Top sponsor listing

About paper bag making machine with printing price in india

Where to Find Paper Bag Making Machine Suppliers with Printing Capabilities?

China remains the dominant global manufacturing hub for integrated paper bag making and printing machinery, with concentrated supplier clusters in Shandong and Hebei provinces. These regions host vertically integrated production ecosystems that combine precision engineering, packaging automation expertise, and flexible customization capacity. Shandong’s industrial base benefits from proximity to major ports and a mature supply chain for core components such as flexographic printing units, PLC control systems, and die-cutting modules, enabling cost efficiencies of 20–35% compared to Western or Indian manufacturers.

Suppliers in this region typically operate multi-functional facilities capable of producing standalone machines or fully automated lines combining forming, printing, handle insertion, and packaging stages. The average lead time for standard configurations ranges from 30 to 45 days, with expedited builds possible for pre-configured models. Buyers gain access to scalable solutions—from semi-automatic entry-level units priced under $5,000 to high-speed, multi-color printing lines exceeding $25,000—supporting both small-scale entrepreneurs and industrial packaging operations.

How to Choose Paper Bag Making Machine Suppliers with Printing Functionality?

Procurement decisions should be guided by systematic evaluation of technical capability, operational reliability, and transactional safeguards:

Technical Specifications & Compliance

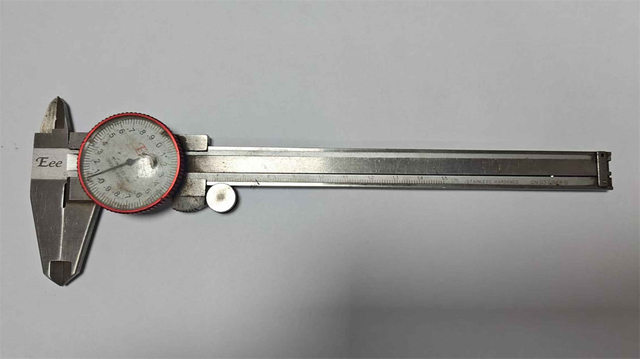

Confirm machine compatibility with required paper weights (typically 60–180 gsm kraft or art paper) and bag dimensions (width: 100–600 mm; height: 150–500 mm). Prioritize suppliers offering CE compliance or equivalent safety certifications, particularly for electrical systems and moving parts. For export-focused buyers, verify adherence to international standards such as ISO 12100 (machinery safety) and IEC 60204-1 (electrical equipment).

Production Capacity Verification

Assess infrastructure maturity through key indicators:

- Minimum factory area of 3,000m² indicating established production footprint

- In-house engineering teams supporting custom modifications (e.g., color registration accuracy, sealing temperature control)

- Integrated testing protocols for print alignment, glue application consistency, and output speed stability

Cross-reference on-time delivery performance (target ≥97%) and response times (≤3 hours preferred) as proxies for operational efficiency.

Customization and Transaction Security

Require detailed mockups and technical drawings before order confirmation. Evaluate suppliers offering modular designs that allow future upgrades (e.g., adding lamination or UV coating stations). Utilize secure payment mechanisms such as escrow services to mitigate risk, especially when dealing with new partners. Insist on sample testing under real operating conditions—benchmark print clarity, bag strength, and downtime frequency prior to full deployment.

What Are the Leading Paper Bag Making Machine Suppliers with Printing Options?

| Company Name | Type | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Estimate |

|---|---|---|---|---|---|---|---|---|

| SENIOR PAPER PACKAGING MACHINERY MFG COMPANY | Manufacturer | Paper Bag Machines, Flexo Printers | $11,997–28,000 | 1 set/pair | Not specified | ≤1h | Not specified | Not specified |

| AVTAR MECHANICAL WORKS | Manufacturer | Fully Automatic Bag Makers, Flexographic Printers | $10,300–16,500 | 1 piece | Not specified | ≤3h | Not specified | Not specified |

| Shandong Weiao Machine Equipment Co., Ltd. | Manufacturer | Bag Making Machines, Laminators, Printers | $3,000–21,000 | 1 set | 100% | ≤6h | <15% | US $470,000+ |

| ALL INDIA MACHINERY | Distributor/Supplier | Single Station Printers, Bag Makers | $450–4,600 | 1 piece | Not specified | ≤3h | Not specified | Not specified |

| Shijiazhuang Chuangmei Paper Products Co., Ltd. | Custom Manufacturer | Paper Bags, Cups, Boxes | Not listed | Not listed | 100% | Not available | 16% | US $80,000+ |

Performance Analysis

SENIOR PAPER PACKAGING offers premium-tier equipment with advanced PLC integration and four-color flexo printing capabilities, targeting high-volume producers requiring consistent graphic quality. AVTAR MECHANICAL WORKS provides competitively priced automatic systems ideal for mid-range commercial applications, with pricing aligned to Indian market demands. Shandong Weiao stands out for proven logistics performance (100% on-time delivery) and substantial online sales volume (over $470,000), suggesting strong post-sale support and scalability. ALL INDIA MACHINERY caters to budget-conscious buyers with entry-level single-station printers, though limited technical data raises due diligence requirements. Shijiazhuang Chuangmei, while primarily an end-product manufacturer, demonstrates repeat customer engagement (16% reorder rate), potentially offering hybrid sourcing opportunities for buyers seeking integrated machine-and-material partnerships.

FAQs

How to verify paper bag machine supplier credibility?

Cross-check declared certifications with official registries. Request video audits of assembly lines and quality control checkpoints. Analyze customer feedback focusing on after-sales service, spare parts availability, and uptime performance. Prioritize suppliers providing documented maintenance schedules and operator training programs.

What is the typical minimum order quantity (MOQ)?

Most manufacturers set MOQ at 1 unit for standard machines. Customized or turnkey lines may require higher commitments. Some suppliers waive MOQ for sample units at slightly increased per-unit costs.

Can these machines handle biodegradable or specialty papers?

Yes, provided the machine's feeding and sealing systems are calibrated for variable thickness and moisture content. Confirm compatibility with materials such as recycled kraft, PLA-coated paper, or water-based laminates before procurement.

Do suppliers offer installation and training support?

Reputable manufacturers typically provide remote setup guidance via video. On-site commissioning and technician training are often available at additional cost. Verify language proficiency and regional service coverage during negotiations.

What customization options are commonly available?

Common modifications include adjustable print stations (1–6 colors), handle dispensing automation, embossing modules, and integrated weighing/packaging systems. Suppliers may also customize discharge conveyors, control panel interfaces, and safety enclosures based on facility layout requirements.