Paper Box Making Machine Price

CN

CN

Top sponsor listing

Top sponsor listing

About paper box making machine price

Where to Find Paper Box Making Machine Suppliers?

China remains the global epicenter for paper box making machine manufacturing, with key industrial clusters concentrated in Hebei and Henan provinces. Dongguang County in Hebei hosts a dense network of packaging machinery producers specializing in carton forming, die-cutting, and gluing systems. This region benefits from decades of accumulated technical expertise and vertically integrated supply chains for components such as servo motors, pneumatic systems, and precision molds.

Henan’s Zhengzhou district complements this ecosystem with advanced R&D capabilities in automated food-grade packaging lines, particularly for disposable lunch boxes, pizza containers, and takeaway trays. The proximity to raw material suppliers—kraft paper mills, wax coating facilities, and adhesive producers—enables cost reductions of 18–25% compared to non-specialized regions. Buyers gain access to scalable production environments where lead times average 30–45 days for standard configurations, with expedited builds possible within 20 days for semi-automatic models.

How to Choose Paper Box Making Machine Suppliers?

Procurement decisions should be guided by rigorous supplier evaluation protocols:

Technical Capability Verification

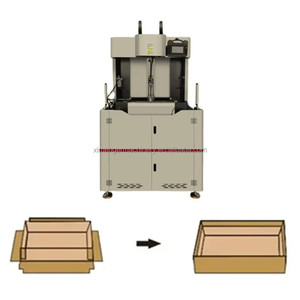

Confirm equipment specifications align with intended output requirements: production speed (ranging from 30 to 200 boxes per minute), material compatibility (single/double-wall corrugated board, kraft paper, coated cardboard), and dimensional flexibility (adjustable molds for box sizes). Demand detailed schematics and operational manuals prior to purchase.

Production Infrastructure Assessment

Evaluate supplier capacity through measurable indicators:

- Minimum factory footprint of 3,000m² for full-line assembly

- In-house engineering teams capable of custom tooling design

- Integration of CNC machining and laser alignment systems

Cross-reference on-time delivery rates (target ≥97%) and response time metrics (≤5 hours) to assess operational reliability.

Transaction Security Measures

Utilize secure payment mechanisms such as escrow services or letter of credit arrangements until post-delivery performance verification is completed. Prioritize suppliers with documented quality management systems and proven export experience to North America, Europe, or Southeast Asia. Pre-shipment inspection reports and third-party testing certifications enhance risk mitigation.

What Are the Best Paper Box Making Machine Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Dongguang County Huayu Carton Machinery Co., Ltd. | Carton Printing, Slotting, Die-Cutting, Gluing Machines | Data not available | Not specified | 100% | ≤5h | Unreported | Color, material, size, logo, packaging, label, graphic | Unreported |

| Zhengzhou Enson Industrial Co., Ltd. | Paper Product Making Machinery, Laminating, Coating Machines | $7,000–$18,460 | 1 set | 100% | ≤1h | 100% | Not explicitly stated | US $10,000+ |

| Dongguang Xinlong Packaging Machinery Co., Ltd. | Packaging Forming, Gluing, Die-Cutting, High-Speed Corrugated Lines | $30,000–$500,000 | 1 unit/set | 100% | ≤5h | <15% | Not explicitly stated | US $60,000+ |

| Zhengzhou Mona Machinery Co., Ltd. | High-Speed Automatic Biodegradable Box Machines | $1,688–$8,998 | 1 set | 100% | ≤4h | 60% | Not explicitly stated | US $80,000+ |

| Cangzhou Ocean Carton Machinery Manufacturer Co., Ltd. | Semi-Automatic Corrugated Box Machines, Die-Cutters | $4,900–$39,800 | 1 set | 100% | ≤3h | 50% | Color, shape, size, die cutter, slotter | US $400,000+ |

Performance Analysis

Dongguang-based manufacturers focus on heavy-duty corrugated box lines with high capital investment thresholds (up to $500,000), suitable for large-scale packaging operations. In contrast, Zhengzhou suppliers offer competitively priced compact machines targeting small-to-mid volume producers, with entry-level models starting under $2,000. Cangzhou Ocean and Zhengzhou Enson demonstrate strong transactional reliability, combining 100% on-time delivery with sub-5-hour response times and significant reorder activity—indicative of customer satisfaction. Suppliers like Zhengzhou Mona achieve higher reorder rates (60%) despite narrower product specialization, suggesting effective after-sales support and machine durability. For buyers prioritizing customization, Huayu and Ocean provide explicit options for branding integration and structural adaptation.

FAQs

What is the typical MOQ for paper box making machines?

The standard minimum order quantity is 1 set or unit across all major suppliers. No batch discounts are required to initiate procurement, although bulk purchases may qualify for reduced shipping costs or extended warranty terms.

How long does it take to fulfill an order?

Lead times range from 15 to 45 days depending on automation level. Manual and semi-automatic models typically ship within 20 days, while fully automatic, high-speed production lines require 30–45 days for assembly, calibration, and testing.

Can these machines handle biodegradable or food-safe materials?

Yes, select suppliers offer machines engineered for food-grade kraft paper and compostable coatings. Ensure compliance with FDA or EU food contact material regulations by requesting material traceability documentation and surface finish certifications.

Do suppliers provide installation and training support?

Most manufacturers include remote setup guidance via video tutorials and live troubleshooting. On-site technician deployment is available at additional cost, typically quoted separately based on destination and duration.

Are customization requests feasible for unique box designs?

Yes, suppliers with dedicated R&D teams can modify folding patterns, creasing dies, and feeding mechanisms to accommodate non-standard geometries such as gable tops, partition inserts, or magnetic closures. Provide CAD drawings or physical samples to initiate tooling development.