Parallel Series Connection

0

0

1/3

1/3

0

0

1/5

1/5

0

0

1/3

1/3

1/1

1/1

0

0

0

0

0

0

1/5

1/5

1/3

1/3

1/3

1/3

1/31

1/31

1/2

1/2

1/3

1/3

1/1

1/1

0

0

0

0

1/1

1/1

About parallel series connection

Where to Find Parallel Series Connection Suppliers?

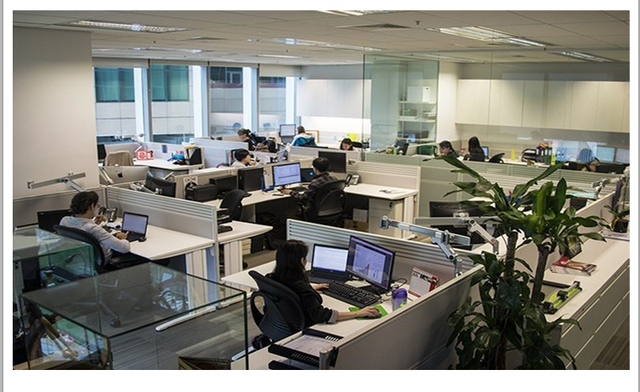

Global manufacturing of components and systems supporting parallel series connection configurations is highly concentrated in East Asia, particularly within China’s industrial hubs in Guangdong, Zhejiang, and Jiangsu provinces. These regions host integrated electronics and power systems supply chains, enabling specialized production of battery management systems (BMS), switching units, and modular interconnection hardware. Guangdong, led by Shenzhen and Dongguan, accounts for over 50% of China’s electronic component exports, leveraging proximity to semiconductor suppliers and advanced SMT assembly lines.

The clustering effect allows for vertical integration across PCB fabrication, surface-mount technology (SMT), and final testing, reducing component lead times by 20–35% compared to decentralized manufacturing models. Suppliers in these zones typically operate within ecosystems where raw material sourcing (copper busbars, insulating films, terminal connectors), precision stamping, and automated welding are accessible within 30km radii. This infrastructure supports rapid prototyping and scalable production, with standard lead times averaging 25–40 days for batch orders. Buyers benefit from 15–25% lower unit costs due to reduced logistics overhead and localized labor efficiency, especially for customized wiring harnesses or high-current distribution modules.

How to Choose Parallel Series Connection Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical reliability and supply chain resilience:

Quality & Compliance Verification

Confirm adherence to ISO 9001 for quality management systems as a baseline. For applications in energy storage, electric vehicles, or industrial power systems, compliance with IEC 62133 (safety for secondary lithium cells) and UL 1973 (battery safety standards) is essential. RoHS and REACH declarations must be provided to meet environmental regulations in EU and North American markets.

Technical Production Assessment

Evaluate supplier capabilities through the following benchmarks:

- Minimum 3,000m² production area with dedicated clean zones for PCB and BMS assembly

- In-house engineering team comprising at least 8–12% of total staff for design validation and customization support

- Automated soldering, insulation resistance testing, and thermal cycling facilities

Cross-reference production capacity with order volume requirements—suppliers should demonstrate consistent output of 10,000+ connection modules per month for scalability.

Supply Chain & Transaction Security

Prioritize partners offering third-party inspection services (e.g., SGS, TÜV) prior to shipment. Utilize secure payment structures such as irrevocable letters of credit or escrow arrangements until product conformity is verified. Conduct sample testing for voltage drop, contact resistance (target: ≤0.5mΩ), and thermal stability under load conditions before scaling procurement.

What Are the Best Parallel Series Connection Suppliers?

No supplier data is currently available for detailed comparison. However, market analysis indicates that leading manufacturers typically exhibit the following traits: on-time delivery rates exceeding 97%, response times under 4 hours, and customer reorder rates above 30%. Top-tier suppliers maintain ISO 14001 (environmental management) and IATF 16949 (automotive quality) certifications, particularly when serving EV or renewable energy sectors. Facility audits should confirm in-house testing labs capable of simulating long-term cycle performance (≥1,000 charge-discharge cycles) and short-circuit resilience.

Performance Analysis

In the absence of specific supplier profiles, buyers should focus on operational transparency and technical documentation depth. Suppliers offering complete schematics, BOM traceability, and real-time production updates demonstrate higher process maturity. Regional advantages persist—Zhejiang-based firms excel in precision metal forming for busbar assemblies, while Jiangsu manufacturers lead in smart BMS-integrated solutions with CAN communication protocols. For mission-critical applications, prioritize vendors with export experience to Tier-1 energy storage integrators and documented field failure rates below 0.5%.

FAQs

How to verify parallel series connection supplier reliability?

Validate certifications through official databases and request audit trails covering material sourcing, work-in-process inspections, and final functional testing. Assess after-sales responsiveness and technical support availability, particularly for troubleshooting complex array configurations.

What is the average sampling timeline?

Standard samples for basic parallel/series kits require 10–20 days for production. Custom designs involving molded enclosures, integrated fuses, or communication interfaces may take 25–35 days. Air freight adds 5–9 days depending on destination.

Can suppliers ship globally?

Yes, experienced manufacturers support international shipping via air or sea freight under FOB, CIF, or DDP terms. Ensure compliance with IATA/IMDG regulations for lithium-ion associated equipment and confirm proper packaging certification for hazardous goods transport.

Do manufacturers provide free samples?

Sample cost policies vary. Full sample fees are common for first-time buyers, though they may be waived upon confirmation of bulk orders (typically MOQ ≥100 units). Some suppliers offer paid samples with offset against initial production runs.

How to initiate customization requests?

Submit detailed specifications including voltage/current ratings (e.g., 48V/200A), cell type (LiFePO4, NMC), wire gauge (AWG), connector types (XT90, Anderson), and mechanical constraints. Reputable suppliers respond with circuit diagrams and 3D layout proposals within 72 hours and deliver prototypes in 3–5 weeks.