Patch Panel Label Maker

CN

CN

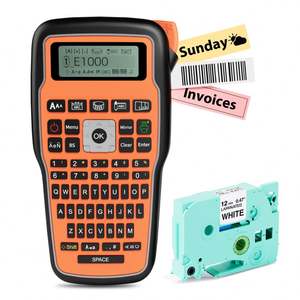

About patch panel label maker

Where to Find Patch Panel Label Maker Suppliers?

China remains the central hub for patch panel label maker production, with key manufacturing clusters in Guangdong and Zhejiang provinces driving innovation and cost efficiency. Guangdong, particularly Shenzhen and Dongguan, hosts advanced electronics and industrial automation suppliers leveraging proximity to semiconductor and telecommunications component suppliers. This integration reduces material lead times by 20–30% compared to offshore alternatives. Zhejiang’s Wenzhou region specializes in precision packaging machinery, offering mature supply chains for labeling applicators and dispensing systems used in network infrastructure applications.

These industrial ecosystems support vertically integrated operations—from PCB assembly to mechanical housing fabrication—enabling rapid prototyping and scalable production. Buyers benefit from concentrated technical expertise, with over 70% of suppliers maintaining in-house R&D teams focused on electromechanical control systems. Typical advantages include MOQ flexibility (from single units to bulk sets), lead times averaging 15–30 days for standard configurations, and competitive pricing due to localized sourcing of motors, sensors, and thermal printing modules.

How to Choose Patch Panel Label Maker Suppliers?

Effective supplier selection requires structured evaluation across three core dimensions:

Technical Capability Verification

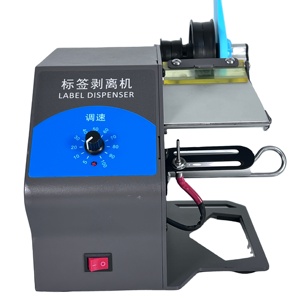

Confirm compatibility with industry-standard labeling formats (e.g., 23mm–30mm wide tapes, PVC/thermal transfer substrates). For automated dispensers or peelers, assess motor torque, sensor accuracy, and integration potential with existing network documentation software. While explicit ISO 9001 certification is not universally listed, prioritize suppliers documenting internal quality management protocols, especially those serving telecom or data center clients requiring traceable labeling processes.

Production & Operational Metrics

Evaluate operational reliability using available performance indicators:

- On-time delivery rate ≥95% indicates stable production planning

- Response time ≤2 hours reflects strong customer support infrastructure

- Reorder rate below 20% suggests limited post-sale issues or fulfillment gaps

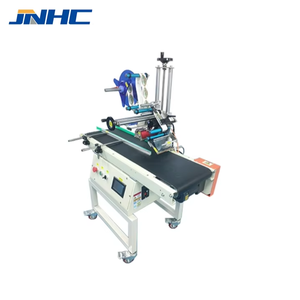

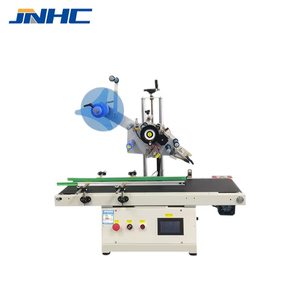

Cross-reference product specifications with facility scale—suppliers offering both-oriented machines typically operate facilities exceeding 2,000m² with dedicated testing stations.

Transaction Risk Mitigation

Utilize secure payment frameworks that align with international trade standards. Request sample validation before full-order release, particularly for custom voltage requirements (110V vs. 220V) or specialized label feed mechanisms. Verify export experience through shipment history and logistics partnerships, ensuring compliance with destination-market electrical safety regulations where applicable.

What Are the Best Patch Panel Label Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

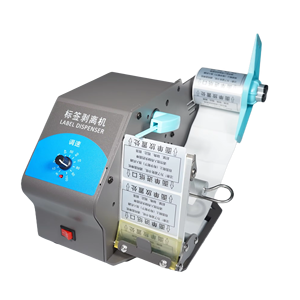

| Guangzhou Bishixi Technology Co., Ltd | Guangdong, CN | Label Dispensers, Rewinders, Thermal Printers | US $90,000+ | 100% | ≤2h | <15% | 1 unit | $37.70–$225 |

| Shenzhen Mechtron Machinery Co., Ltd. | Guangdong, CN | Automatic Labeling Machines, Applicators | US $9,000+ | 100% | ≤2h | <15% | 1 set | $1,212–$2,220 |

| Wenzhou Lianteng Packaging Machinery Co., Ltd. | Zhejiang, CN | Semi-Automatic & Desktop Labelers | US $90,000+ | 74% | ≤5h | 20% | 1 set | $420–$2,399 |

| Dongguan Do Hearts Technology Co., Ltd. | Guangdong, CN | PVC Patch & Liquid Label Machinery | US $5,000+ | 100% | ≤4h | <15% | 1 piece/set | $1,500–$5,000 |

| Shenzhen Sunpinsgar Gift Co., Ltd. | Guangdong, CN | Fabric & Custom Textile Labels | US $70,000+ | 100% | ≤2h | 45% | 100 pieces | $0.17–$0.40/unit |

Performance Analysis

Guangzhou Bishixi stands out for entry-level automation with low MOQs and single-unit pricing, ideal for small-scale network maintenance operations. Shenzhen Mechtron offers high-precision automatic labeling systems suited for enterprise-grade patch panel production lines, backed by consistent delivery performance. Wenzhou Lianteng provides mid-range semi-automatic solutions but exhibits lower on-time fulfillment (74%), suggesting potential bottlenecks in order processing. Dongguan Do Hearts focuses on specialty liquid PVC labeling equipment, targeting niche OEMs producing durable outdoor-rated labels. Shenzhen Sunpinsgar diverges from machinery supply, offering pre-made textile and heat-seal labels at ultra-low unit costs—optimal for branding rather than field labeling tasks. Buyers prioritizing automation should focus on Guangdong-based integrators with documented machine-vision or servo-control capabilities.

FAQs

How to verify patch panel label maker supplier reliability?

Assess consistency in delivery performance (target ≥95%), response speed (≤2h preferred), and transaction volume as proxies for operational stability. Request functional videos or third-party inspection reports for critical components such as dispensing rollers, tension controls, and print head durability. Validate compatibility with common label materials (polyester, vinyl, thermal) used in structured cabling environments.

What is the typical sampling timeline?

Standard sample processing takes 7–14 days for off-the-shelf models. Customized versions requiring firmware adjustments or mechanical modifications may require 20–30 days. Air freight adds 5–10 days for international delivery, depending on destination region.

Can suppliers provide customized voltage or language interfaces?

Yes, most machinery-focused suppliers offer dual-voltage options (110V/220V) and basic UI localization upon request. Confirm modification feasibility during initial inquiry, as retrofitting may extend lead times by 10–15 days. Documentation and technical support are typically provided in English.

Do manufacturers support private labeling or OEM branding?

Many suppliers accept OEM orders, including logo engraving, custom color housings, and branded packaging. Minimum thresholds vary: Guangzhou Bishixi and Wenzhou Lianteng typically require 50+ units for branding, while Shenzhen Sunpinsgar accommodates smaller runs for textile labels.

What are standard payment and shipping terms?

Common payment methods include T/T (30% deposit, 70% before shipment) and secure escrow arrangements. FOB terms are standard; buyers assume responsibility post-loading. Sea freight is economical for container loads (20ft+), while express air shipping suits urgent single-unit deliveries. Confirm incoterms and insurance coverage prior to order confirmation.