Pc Components Producer

About pc components producer

Where to Find PC Components Producers?

China remains the global epicenter for PC components manufacturing, with Shenzhen and Dongguan in Guangdong Province forming high-density industrial hubs for electronics production. These regions host vertically integrated supply chains encompassing PCB fabrication, surface-mount technology (SMT) assembly, and final system integration. Shenzhen alone accounts for over 60% of China’s export-oriented electronics manufacturers, supported by mature logistics networks enabling air freight dispatch within 24 hours of order confirmation.

The concentration of technical talent and component suppliers within a 50km radius allows for rapid prototyping and scalable production. Manufacturers benefit from localized access to raw materials such as FR-4 substrates, copper foils, and solder pastes, reducing material lead times by 10–15 days compared to offshore alternatives. Buyers can expect standard lead times of 7–14 days for prototype PCBAs and 20–30 days for mass production runs, depending on complexity and order volume. Cost efficiencies range from 20–40% versus equivalent production in North America or Europe due to lower labor costs and streamlined regulatory processes.

How to Choose PC Components Producers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Management Systems

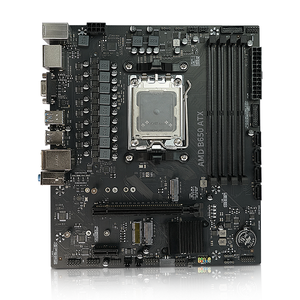

Verify compliance with IPC-A-610 Class 2 standards for electronic assemblies as a baseline. For regulated industries (medical, automotive, industrial), demand ISO 9001 certification and adherence to RoHS/REACH environmental directives. Suppliers should provide test reports including AOI (Automated Optical Inspection), X-ray inspection for BGA joints, and functional testing protocols.

Production Capacity Assessment

Evaluate key infrastructure indicators:

- Minimum SMT line capacity of 50,000 components per hour

- In-house capabilities covering single-sided, double-sided, and multilayer PCB assembly (up to 16 layers)

- Support for both through-hole (DIP) and surface-mount (SMT) technologies

Cross-reference declared output volumes with verified on-time delivery rates (target ≥95%) and reorder rates to assess reliability and customer satisfaction.

Customization & Transaction Security

Prioritize suppliers offering full OEM/ODM services, including schematic design, layout, component sourcing, and enclosure integration. Confirm support for customizations in material grade (e.g., 94V-0 flame-rated substrates), color, labeling, and packaging. Utilize secure payment mechanisms tied to milestone deliveries. Request sample batches before committing to large orders to validate build quality and documentation accuracy.

What Are the Leading PC Components Producers?

| Company Name | Location | Years Operating | Main Products | MOQ Range | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Yongchangtai Electronics Co., Ltd. | Shenzhen, CN | 15+ | PCBA, Custom Circuit Boards | 1–100 pcs | 100% | ≤2h | <15% | US $1,000+ |

| Dongguan Zhiyi Kefeng Electronics Co., Ltd. | Dongguan, CN | — | Industrial Motherboards, SMT Processing | 1 pc/set | 100% | ≤2h | — | — |

| Shenzhen Lihua Technology Co., Ltd. | Shenzhen, CN | — | PCBA, Multilayer PCBs, Camera Modules | 1–10 pcs | 95% | ≤7h | 45% | US $750,000+ |

| ShenZhen Sky-Win Technology CO.,LTD | Shenzhen, CN | 20+ | PCBA, High-Speed PCB Assembly | 5–50,000 pcs | 100% | ≤2h | <15% | US $500,000+ |

| Shenzhen Yongkefeng Technology Co., Ltd. | Shenzhen, CN | — | Multilayer PCB, FPC, ARM Core Boards | 1 pc | 100% | ≤1h | 20% | US $120,000+ |

Performance Analysis

Established producers like ShenZhen Sky-Win and Shenzhen Yongchangtai demonstrate consistent on-time performance (100% delivery rate) and fast response cycles, critical for agile development environments. Shenzhen Lihua Technology stands out with a high reorder rate (45%), indicating strong customer retention likely driven by robust multilayer PCB and module-level integration capabilities. Newer entrants maintain competitive responsiveness—Shenzhen Yongkefeng achieves sub-one-hour average reply times—making them suitable for time-sensitive design iterations. Suppliers with revenues exceeding US $500,000 annually typically operate multiple SMT lines and offer turnkey solutions, whereas smaller-volume producers may specialize in niche applications such as rigid-flex boards or miniaturized embedded systems.

FAQs

How to verify PC components producer credibility?

Request copies of business licenses and cross-check against government registries. Validate claims of certifications (ISO, RoHS) through accredited third-party databases. Analyze transaction history, focusing on dispute resolution records and buyer feedback related to product consistency and post-sale support.

What is the typical sampling timeline for custom PC components?

Prototype PCBAs are generally delivered within 5–7 days for single-layer designs and 10–12 days for complex multilayer assemblies. Component sourcing delays may extend timelines if specialized ICs or backordered parts are required. Air shipping adds 3–5 days for international delivery.

Do PC components producers support global shipping?

Yes, most suppliers offer international logistics via express carriers (DHL, FedEx) or sea freight for bulk orders. Confirm Incoterms (FOB, CIF, DDP) upfront and ensure compliance with import regulations regarding electronic waste and hazardous materials in the destination market.

Are free samples available from PC components manufacturers?

Sample policies vary: some suppliers waive fees for qualified buyers placing follow-up orders above MOQ thresholds. Others charge partial cost recovery (typically 30–70% of unit price) to cover material and setup expenses. Negotiate sample terms during initial inquiry to clarify financial obligations.

How to initiate customization for PC components?

Submit detailed specifications including Gerber files, BOM (Bill of Materials), assembly drawings, and any special requirements for impedance control, thermal management, or conformal coating. Reputable manufacturers respond with DFM (Design for Manufacturability) feedback within 48 hours and provide first-article inspection reports upon sample completion.