Pcb Box Build Assembly Services

About pcb box build assembly services

Where to Find PCB Box Build Assembly Services Suppliers?

China remains the global epicenter for end-to-end PCB box build assembly services, with Shenzhen, Hangzhou, and Guangzhou serving as primary manufacturing hubs. These regions host vertically integrated facilities that combine PCB fabrication, surface mount technology (SMT), component sourcing, final enclosure integration, and testing under one roof. The concentration of electronics supply chains in Guangdong and Zhejiang provinces enables rapid prototyping and scalable production, with many suppliers offering turnkey solutions from design validation to fully assembled sub-systems.

The industrial ecosystem supports high flexibility in production volume and complexity, accommodating single prototypes to high-volume runs exceeding 100,000 units monthly. Proximity to component distributors, contract manufacturers, and logistics networks reduces lead times by 20–35% compared to offshore alternatives. Buyers benefit from streamlined coordination across stages—particularly critical in box build assemblies where mechanical enclosures, wiring, firmware loading, and functional testing must be synchronized. Average turnaround for prototype builds ranges from 7–14 days, while full production cycles (including component procurement) typically span 20–30 days.

How to Choose PCB Box Build Assembly Services Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Production & Engineering Capabilities

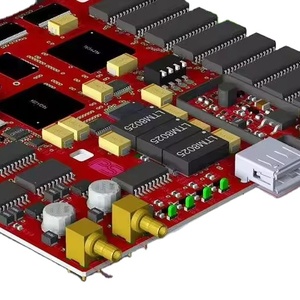

Verify access to SMT lines, automated optical inspection (AOI), in-circuit testing (ICT), and functional test setups. Suppliers handling box builds should demonstrate experience integrating PCBs into custom enclosures, including cable harnessing, labeling, and final packaging. Look for evidence of DFM (Design for Manufacturability) support and firmware programming capabilities. Companies with in-house multilayer PCB fabrication or FPC/ rigid-flex processing offer tighter process control.

Quality Management Systems

While formal ISO 9001 certification is not universally listed, consistent on-time delivery (target ≥94%) and documented testing procedures are strong proxies for quality discipline. Prioritize suppliers providing RoHS compliance documentation and traceability records for components. Reorder rates above 28% indicate customer retention and service reliability. Response times under 2 hours reflect operational responsiveness critical for issue resolution during NPI (New Product Introduction).

Customization and Scalability

Assess customization depth beyond standard PCBA—such as color, material selection, branding (logo, label), and packaging configuration. MOQs vary significantly: some suppliers accept orders as low as 1 piece, ideal for prototyping, while others require 30–100 pieces for cost-effective SMT processing. Unit pricing typically ranges from $0.10 to $15 depending on complexity, layer count, component density, and testing requirements.

Transaction Security and Verification

Review online revenue indicators and reorder metrics as signals of commercial stability. Engage suppliers with transparent communication channels and request sample builds to validate workmanship. For high-volume contracts, conduct virtual or on-site audits to verify equipment capacity, inventory management, and ESD-safe production environments.

What Are the Best PCB Box Build Assembly Services Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Yuetong Electronics Limited | Shenzhen, CN | Customization-focused services | 100% | 55% | ≤2h | $220,000+ | 1 piece | $0.80–5.60 |

| Cheerise Circuits (Hangzhou) Co.,Ltd | Hangzhou, CN | PCBA (59), Other PCB & PCBA (246) | 100% | - | ≤1h | - | 1 piece | $0.10–6.11 |

| Shenzhen Pinkuo Trading Co., Ltd. | Shenzhen, CN | Other ICs (27,742), Microcontrollers (7,245) | 100% | <15% | ≤1h | $20,000+ | 10 pieces | $0.51–15.00 |

| Guangzhou Highleap Electronic Co., Ltd. | Guangzhou, CN | PCBA (541), Rigid-Flex PCB (331) | 94% | 28% | ≤1h | $280,000+ | 1 piece | $0.50–5.00 |

| Shenzhen Yongchangtai Electronics Co., Ltd. | Shenzhen, CN | One-stop OEM/ODM services | 100% | <15% | ≤2h | $1,000+ | 100 pieces | $0.20–5.00 |

Performance Analysis

Shenzhen Yuetong Electronics stands out with a 55% reorder rate and full on-time delivery record, indicating strong client satisfaction and operational consistency. Cheerise Circuits offers the lowest price floor at $0.10 and leads in responsiveness (≤1h), making it suitable for urgent RFQs despite limited reorder data. Guangzhou Highleap provides broad technical coverage with expertise in rigid-flex and aluminum PCBs, backed by substantial transaction volume ($280K+). Shenzhen Pinkuo, while highly responsive and technically capable, shows lower customer retention (<15% reorder rate), suggesting potential gaps in long-term service alignment. Shenzhen Yongchangtai targets high-volume buyers with MOQs of 100 pieces and competitive pricing starting at $0.20, though its minimal online revenue suggests a focus on private-label or B2B partnerships.

FAQs

What certifications should PCB box build suppliers have?

While not all suppliers list ISO or IPC standards, look for evidence of internal quality systems such as AOI, ICT, and functional testing. For regulated industries (medical, automotive), confirm adherence to IPC-A-610 Class 2/3 and ISO 13485 if applicable. RoHS compliance is standard for EU-bound products.

What is the typical lead time for box build assemblies?

Prototypes can be delivered in 7–14 days. Full production—including component sourcing, assembly, and system integration—typically takes 20–30 days. Lead times may extend if key components are backordered or require custom tooling.

Can suppliers handle component sourcing and BOM fulfillment?

Yes, most offer full turnkey services, managing BOM analysis, component procurement, and counterfeit risk mitigation. Suppliers with large listing volumes in ICs and electronic modules (e.g., Shenzhen Pinkuo) demonstrate established sourcing networks.

Do PCB box build providers support small-batch or prototype orders?

Many suppliers accept MOQs as low as 1 piece, particularly for initial builds. However, unit costs decrease significantly at 100+ units due to fixed setup charges for stencil creation and SMT line configuration.

How to evaluate assembly quality before scaling?

Request sample units to inspect solder joints, conformal coating (if specified), mechanical fit within the enclosure, and basic functionality. Ask for process documentation, including X-ray reports for BGAs and test logs. Video tours of the production floor can verify ESD controls and workflow organization.