Performance Testing

Top sponsor listing

Top sponsor listing

1/3

1/3

CN

CN

1/3

1/3

1/3

1/3

1/12

1/12

1/15

1/15

CN

CN

1/27

1/27

1/3

1/3

1/3

1/3

1/2

1/2

1/2

1/2

1/3

1/3

1/3

1/3

1/18

1/18

CN

CN

1/19

1/19

1/15

1/15

1/1

1/1

About performance testing

Where to Find Performance Testing Equipment Suppliers?

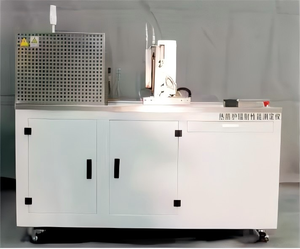

China remains a central hub for performance testing equipment manufacturing, with key production clusters in Guangdong and Fujian provinces driving innovation and export capacity. Guangdong hosts a high concentration of precision instrument manufacturers, particularly in Dongguan and Guangzhou, where integrated electronics and mechanical engineering ecosystems support rapid prototyping and scalable production. Fujian’s Xiamen region specializes in non-destructive testing (NDT) and analytical instrumentation, leveraging localized R&D partnerships with technical institutes to enhance product accuracy and reliability.

These industrial zones benefit from vertically aligned supply chains—spanning sensor fabrication, control system integration, and calibration services—enabling lead times as short as 20–35 days for standard configurations. Suppliers in these regions typically maintain in-house design teams and CNC machining facilities, reducing dependency on external vendors. Cost advantages range from 18–30% compared to European or North American producers, primarily due to lower labor costs and proximity to raw material sources such as aluminum alloys, stainless steel, and electronic components.

How to Choose Performance Testing Equipment Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical compliance and operational reliability:

Technical Certification & Compliance

Verify adherence to internationally recognized standards such as ISO 9001 for quality management. For export markets, confirm CE marking or IEC conformity where applicable, especially for electrical safety and electromagnetic compatibility. Suppliers should provide test reports for critical subsystems—including sensors, actuators, and data acquisition modules—and demonstrate traceability in calibration processes.

Production and Engineering Capacity

Assess core capabilities through the following indicators:

- Minimum facility size of 2,000m² for dedicated assembly and testing lines

- In-house engineering teams capable of firmware/software customization and mechanical redesign

- Integration of CNC machining, welding, and environmental simulation chambers (e.g., temperature, vibration)

- On-time delivery rate exceeding 96% as an indicator of production stability

Cross-reference supplier claims with verifiable transaction metrics, including response time (ideally ≤2 hours) and reorder rates, which reflect customer satisfaction and post-sale support effectiveness.

Customization and Transaction Security

Confirm availability of OEM/ODM services, including branding (logo, packaging), software interface localization, and extended measurement ranges. Prioritize suppliers offering third-party transaction protection mechanisms and clear dispute resolution protocols. Pre-shipment inspections and sample validation are critical—request functional demonstrations or video audits for high-value systems such as ultrasonic testers or handheld XRF analyzers.

What Are the Best Performance Testing Equipment Suppliers?

| Company Name | Verified Status | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

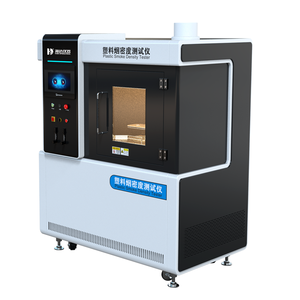

| SKZ International Co., Ltd. | Brand Holder | Gas Analyzers, Moisture Meters, Spectrometers, Water Quality Testers | 96% | ≤1h | <15% | US $340,000+ | Color, material, size, temperature range, logo, packaging, graphic |

| Guangdong Hongyu International Trade Co., Ltd. | - | Tensile Testing Machine, Compression Tester, Viscometer, Chromatograph | 100% | ≤2h | <15% | US $100,000+ | Not specified |

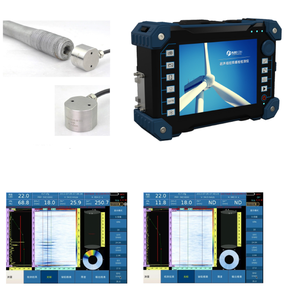

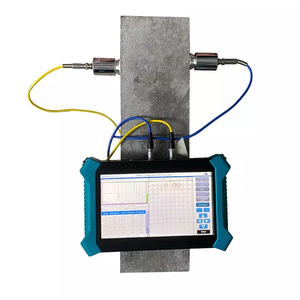

| Xiamen Idea Electronic Technology Co., Ltd. | Multispecialty Supplier | Ultrasonic Testers, XRF Analyzers, Crack Detectors, Eddy Current Machines | 100% | ≤2h | - | - | Analysis modes, color, elements, detector configuration |

| Guangdong ZME Instrument Scientific CO.,LTD | - | Tensile Tester, Force Measuring Instruments, Colorimeter, PCB Thrust Tester | 100% | ≤5h | <15% | US $10,000+ | Not specified |

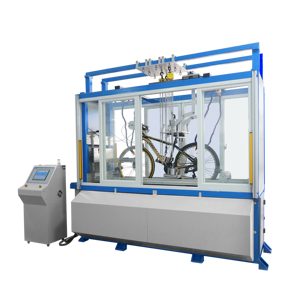

| Dongguan Hongyu Instrument Equipment Co., Ltd. | - | Fatigue Testing Machines, Drop Test Equipment, Dynamic Load Testers | 100% | ≤1h | <15% | US $30,000+ | Not specified |

Performance Analysis

Suppliers like SKZ International and Xiamen Idea distinguish themselves through advanced product specialization and customization depth, particularly in NDT and spectroscopic analysis. All five listed suppliers achieve on-time delivery rates at or above 96%, with three maintaining perfect 100% records—indicating robust production planning. Response times vary significantly: SKZ and Dongguan Hongyu respond within one hour, suggesting strong customer service infrastructure, while Guangdong ZME’s ≤5h benchmark may impact urgent procurement cycles.

Revenue data indicates market tiering—SKZ leads with over US $340,000 in online sales, reflecting broader market reach and inventory diversity. Xiamen Idea focuses on high-end diagnostic tools priced between $7,600 and $32,000 per unit, targeting industrial and aerospace clients requiring certified inspection systems. For buyers prioritizing durability and international compliance, suppliers offering detailed technical documentation and multi-language UI options present lower integration risk.

FAQs

How to verify performance testing equipment supplier reliability?

Validate certifications through official registries and request factory audit reports or video walkthroughs of production and QC lines. Examine product test certificates (e.g., calibration logs, material traceability) and assess after-sales support responsiveness through direct inquiry.

What is the typical minimum order quantity (MOQ)?

Standard MOQ is 1 set across all major suppliers, enabling low-volume trials and pilot deployments. Some suppliers may adjust pricing based on volume, with discounts applicable for orders exceeding five units.

What are common lead times for performance testing equipment?

Lead times range from 15 to 30 days for off-the-shelf models. Custom-built systems—such as electro-hydraulic servo fatigue testers or phased-array ultrasonic detectors—may require 45–60 days depending on complexity and component availability.

Do suppliers offer calibration and after-sales support?

Most suppliers provide basic calibration before shipment. Extended support—including on-site training, repair services, and periodic recalibration—should be confirmed prior to purchase. High-end equipment often includes software updates and remote diagnostics.

Can performance testing equipment be customized for specific industry standards?

Yes. Reputable suppliers accommodate compliance with ASTM, ISO, GB, and DIN standards. Buyers should specify required test protocols (e.g., ISO 7141 for wheel load testing) during quotation to ensure hardware and software alignment.