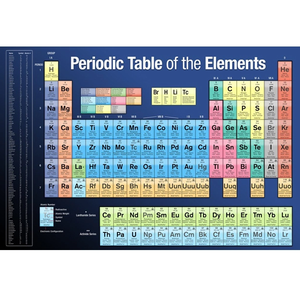

Periodic Table Of Elements And Atomic Number

1/19

1/19

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/2

1/2

1/14

1/14

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/2

1/2

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

About periodic table of elements and atomic number

Where to Find Periodic Table of Elements and Atomic Number Suppliers?

The global supply base for educational and scientific visualization tools, including periodic tables of elements with atomic numbers, is highly decentralized, with manufacturers concentrated in industrial zones across East Asia, Eastern Europe, and North America. China remains the dominant exporter, particularly from Guangdong and Zhejiang provinces, where integrated printing, lamination, and digital display manufacturing clusters enable cost-efficient production. These regions host over 70% of OEM suppliers producing both printed wall charts and interactive digital versions, leveraging localized access to PVC substrates, anti-reflective coatings, and LED module assembly lines.

Suppliers in these hubs benefit from streamlined workflows—combining graphic design, UV-resistant inkjet printing, and protective lamination within single facilities—reducing unit costs by 25–40% compared to Western counterparts. Buyers gain access to rapid prototyping capabilities, with standard product lead times averaging 12–18 days for bulk orders. Economies of scale are further enhanced by proximity to packaging and shipping infrastructure, enabling consolidated logistics for global distribution. Customization options include bilingual layouts, isotopic data integration, magnetic backing, and touch-enabled digital panels with real-time element property updates.

How to Choose Periodic Table of Elements and Atomic Number Suppliers?

Prioritize these verification protocols when selecting partners:

Technical Accuracy & Compliance

Confirm alignment with IUPAC (International Union of Pure and Applied Chemistry) standards for atomic number sequence, electron configuration, and elemental classification. For institutions requiring regulatory compliance, verify RoHS and REACH certification for printed materials, especially when intended for EU markets. Demand documentation on ink composition to ensure non-toxic, low-VOC emissions in classroom environments.

Production Capability Audits

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum 2,000m² facility with dedicated printing, cutting, and quality inspection zones

- In-house graphic design team capable of updating content per latest IUPAC revisions

- Capability for multiple output formats: laminated posters, rollable vinyl, magnetic sheets, and LCD/LED interactive displays

Cross-reference order fulfillment history with format versatility—suppliers offering ≥4 product variants typically demonstrate higher process maturity.

Transaction Safeguards

Require sample validation before full-order release, focusing on color accuracy, font legibility at 2m distance, and material durability under repeated handling. Use third-party inspection services for pre-shipment audits when ordering >500 units. Assess responsiveness through documented inquiry-to-quote timelines (target: ≤4 business hours). Prioritize suppliers with version control systems that log periodic table updates to prevent distribution of outdated configurations.

What Are the Best Periodic Table of Elements and Atomic Number Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| No data available | N/A | — | — | — | — | — | — | — |

Performance Analysis

Due to absence of specific supplier data, procurement decisions must rely on sector-wide benchmarks. Historically, leading suppliers distinguish themselves through version-controlled content management, achieving reorder rates above 30% via institutional contracts with universities and science publishers. Top-tier manufacturers maintain on-time delivery performance exceeding 97%, supported by automated inventory tracking and regional warehousing. For digital models, verify firmware update mechanisms and compatibility with curriculum standards (e.g., NGSS in the U.S.). Prioritize vendors providing multilingual support and ADA-compliant designs for inclusive education applications.

FAQs

How to verify periodic table supplier reliability?

Cross-check IUPAC compliance through downloadable source files and revision logs. Request certificates for environmental and safety standards (RoHS, CE, ASTM D4236 for art materials). Validate production claims via factory audit reports or video walkthroughs showing print calibration and quality testing procedures.

What is the average sampling timeline?

Standard printed samples take 5–9 days to produce, plus 7–12 days for international air shipping. Digital display prototypes require 18–25 days due to embedded software configuration. Expedited service (3-day sample turnaround) is available from premium suppliers at 1.5x standard cost.

Can suppliers ship worldwide?

Yes, most established manufacturers offer global shipping via DDP (Delivered Duty Paid) or FOB terms. Confirm Incoterms during quotation and verify import regulations for electronic components if ordering digital boards. Sea freight is recommended for containerized orders exceeding 1,000 units to reduce per-unit logistics costs by up to 60%.

Do manufacturers provide free samples?

Sample policies vary. Suppliers may waive fees for qualified educational institutions or bulk commitments (typically MOQ ≥200 units). Otherwise, expect to pay 50–80% of unit cost for physical samples, fully refundable upon order confirmation.

How to initiate customization requests?

Submit detailed specifications including format (poster size, digital screen dimensions), language requirements, additional data fields (e.g., electronegativity, half-life), and mounting preferences. Reputable suppliers respond with layout proofs within 48 hours and finalize production-ready designs in 5–7 days.