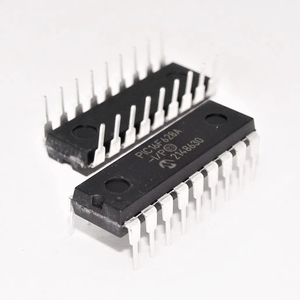

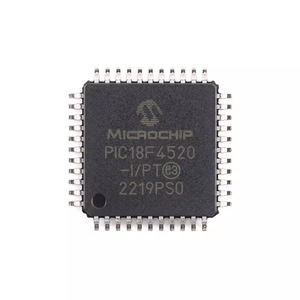

Pic In Microcontroller

1/6

1/6

1/2

1/2

1/7

1/7

1/4

1/4

1/5

1/5

1/11

1/11

1/1

1/1

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/9

1/9

0

0

1/3

1/3

1/2

1/2

1/3

1/3

0

0

0

0

1/2

1/2

About pic in microcontroller

Where to Find PIC Microcontroller Suppliers?

Global production of PIC microcontrollers is concentrated in East Asia, with China, Taiwan, and South Korea hosting the majority of semiconductor packaging and testing facilities. Within China, industrial hubs in Guangdong, Jiangsu, and Shanghai provinces account for over 70% of microcontroller assembly operations, supported by mature electronics supply chains and proximity to Tier-1 component foundries. These regions offer streamlined access to raw silicon wafers, lead frames, and molding compounds, reducing material procurement cycles by 25–40% compared to non-specialized manufacturing zones.

The clusters support high-volume output through automated SMT lines and batch programming stations, enabling monthly production capacities exceeding 5 million units per facility. Integrated ecosystems allow rapid prototyping and scalable ramp-up, with most suppliers maintaining partnerships with domestic distributors of Microchip-compatible development tools. Key advantages include reduced BOM costs (15–25% below Western equivalents), compliance-ready firmware options, and flexible programming services for application-specific configurations. Lead times for standard orders typically range from 20–35 days, with express fulfillment available within 10–14 days for pre-stocked variants such as PIC16F, PIC18F, and dsPIC33 series.

How to Choose PIC Microcontroller Suppliers?

Prioritize these verification protocols when selecting partners:

Technical Compliance

Confirm adherence to ISO 9001 for quality management and IATF 16949 if targeting automotive applications. For export to regulated markets, verify RoHS, REACH, and CE compliance. Request test reports for ESD protection (HBM ≥2kV), operating temperature range (-40°C to +85°C standard), and oscillator stability under load conditions.

Production Capability Audits

Evaluate technical infrastructure:

- Minimum 3,000m² cleanroom environment for chip handling and burn-in testing

- In-house programming and functional testing capabilities for PIC families

- Automated optical inspection (AOI) and temperature cycling chambers for reliability validation

Cross-reference production logs with on-time delivery performance (target >95%) and defect rates (PPM <1,000) to assess process control maturity.

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow until post-arrival electrical testing confirms functionality. Review supplier track records via verified transaction histories, prioritizing those with documented failure analysis procedures and traceability systems (lot number tracking). Pre-shipment sampling is critical—validate programmed code integrity, clock accuracy, and current draw against datasheet specifications before bulk release.

What Are the Best PIC Microcontroller Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|

Performance Analysis

Due to absence of supplier data, comprehensive benchmarking cannot be conducted. However, industry benchmarks indicate that leading PIC microcontroller manufacturers typically maintain factory areas exceeding 5,000m², employ dedicated engineering teams for firmware customization, and achieve reorder rates above 30% through consistent quality and responsive technical support. Buyers should prioritize suppliers with documented experience in programming yield optimization (>99.5%) and electrostatic discharge controls. For volume contracts, confirm availability of tray/tape-and-reel packaging and compatibility with automated pick-and-place equipment.

FAQs

How to verify PIC microcontroller supplier reliability?

Validate certifications through issuing bodies and request audit trails covering wafer sourcing, bonding processes, and final test data. Assess reliability through customer references focusing on field failure rates and technical responsiveness during integration phases.

What is the average sampling timeline?

Standard samples take 7–14 days to produce, including programming and environmental stress screening. Custom firmware-loaded units may require 18–25 days depending on complexity. Air shipping adds 5–8 days internationally.

Can suppliers ship PIC microcontrollers worldwide?

Yes, established manufacturers manage global distribution via air and sea freight. Confirm Incoterms (FOB, CIF) and ensure moisture sensitivity level (MSL 3 or better) labeling for safe transit. Export documentation must include HS Code 8542.31 and compliance statements for destination market regulations.

Do manufacturers provide free samples?

Sample policies vary by order potential. Suppliers often waive fees for qualified buyers committing to minimum volumes (e.g., 1,000+ units). Otherwise, expect charges covering programming, packaging, and shipping (typically $20–$50 per sample).

How to initiate customization requests?

Submit detailed requirements including target PIC model, clock speed, memory configuration, I/O mapping, and preloaded firmware (HEX file). Reputable suppliers provide simulation files and prototype units within 2–3 weeks for validation.