Pipe Thread Making Machine

Top sponsor listing

Top sponsor listing

1/3

1/3

1/14

1/14

1/1

1/1

1/12

1/12

0

0

1/3

1/3

1/3

1/3

1/12

1/12

CN

CN

1/15

1/15

0

0

1/3

1/3

0

0

1/14

1/14

1/15

1/15

0

0

1/14

1/14

1/16

1/16

About pipe thread making machine

Where to Find Pipe Thread Making Machine Suppliers?

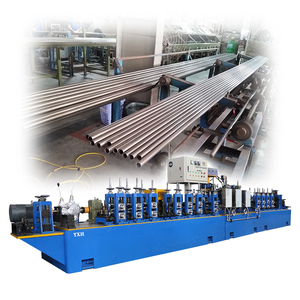

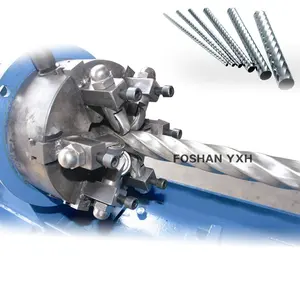

China remains the central hub for pipe thread making machine manufacturing, with key production clusters in Guangdong, Henan, and Shandong provinces. Foshan in Guangdong province hosts a concentrated industrial base for metalworking and tube processing machinery, enabling suppliers like Foshan YXH Tube Mill & Mould Co., Ltd. to leverage vertical integration from mold design to final assembly. This ecosystem supports rapid prototyping and customization of threading components, including die heads and roller systems.

Henan-based manufacturers such as Henan Shanpu Machinery Equipment Co., Ltd. and Zhengzhou Jujing Machinery Equipment Co., Ltd. specialize in portable electric threading devices, benefiting from regional access to motor, gearbox, and power tool component suppliers. These clusters offer cost efficiencies through localized sourcing, reducing material procurement cycles by 20–30% compared to non-specialized regions. Buyers gain access to scalable production networks capable of fulfilling orders ranging from single units to container-sized batches, with average lead times between 15 and 30 days for standard models.

How to Choose Pipe Thread Making Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities and Customization

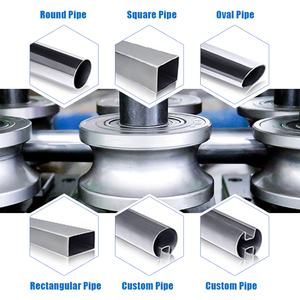

Assess whether suppliers support required specifications: thread types (NPT, BSPT, metric), pipe diameter range (typically 1/2" to 6"), material compatibility (carbon steel, stainless steel, galvanized pipe), and automation level (manual, semi-automatic, fully automatic). Multiple suppliers in the dataset offer customization options for spindle speed, roller diameter, thread pitch, and labeling—critical for OEM integration or region-specific compliance.

Production and Quality Assurance

Prioritize suppliers with documented quality management systems. While explicit ISO certification is not listed in the provided data, high on-time delivery rates (e.g., 100% for Foshan YXH, Xingtai Judu, and Tengzhou Uni-Tech) indicate robust internal processes. Evaluate production capacity through available metrics:

- Facility size and in-house machining capabilities (CNC, welding, heat treatment)

- Dedicated R&D teams for custom engineering

- Testing protocols for torque output, thread accuracy, and motor endurance

Cross-reference product listings with response time (≤3h for most top performers) and reorder rate as indirect indicators of customer satisfaction and post-sale reliability.

Procurement and Transaction Security

Minimum order quantities vary significantly—from 1 piece for handheld models to 5–10 sets for industrial-grade machines. Unit prices range from $174 for basic electric threaders to over $11,000 for automated systems. Use platform-verified transaction histories to assess financial reliability. Where possible, require sample testing under real-world conditions before full-scale ordering. Confirm packaging standards and export documentation readiness, especially for CE-marked equipment destined for EU markets.

What Are the Best Pipe Thread Making Machine Suppliers?

| Company Name | Supplier Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Foshan YXH Tube Mill & Mould Co., Ltd. | Custom Manufacturer | Pipe Making Machinery, Metal Polishing Machines | US $910,000+ | 100% | ≤3h | 80% | Diameter, material thickness, design |

| Xingtai Judu Technology Co., Ltd. | Not specified | Automatic Pipe Threading Machines, Rebar Threading | US $70,000+ | 100% | ≤2h | <15% | Spindle speed, roller width, thread length, logo |

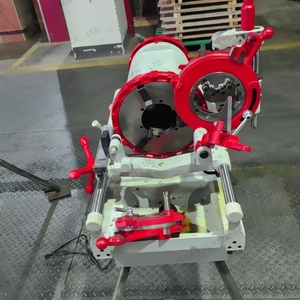

| Tengzhou Uni-Tech Co., Ltd. | Multispecialty Supplier | Die Head Threading, Portable Electric Threaders | US $30,000+ | 100% | ≤4h | <15% | Thread type, size, color, packaging, label |

| Henan Shanpu Machinery Equipment Co., Ltd. | Not specified | Portable Electric Pipe Threaders | US $110,000+ | 91% | ≤3h | <15% | Limited (not explicitly stated) |

| Zhengzhou Jujing Machinery Equipment Co., Ltd. | Not specified | Power Pipe Threaders, Pipe Cutting Machines | US $20,000+ | 100% | ≤4h | <15% | Not explicitly stated |

Performance Analysis

Foshan YXH stands out with the highest online revenue and an exceptional 80% reorder rate, suggesting strong customer retention and satisfaction—likely driven by its specialization in pipe making machinery and extensive customization capabilities. Xingtai Judu Technology offers high-end automated solutions priced above $5,500 per unit, supported by granular customization and a sub-2-hour response time, positioning it for precision industrial buyers. Tengzhou Uni-Tech provides flexibility in branding and configuration, suitable for distributors requiring private labeling. Henan Shanpu leads in volume-oriented portable models with competitive pricing ($174–$473), though its lower reorder rate indicates potential gaps in after-sales service or long-term reliability.

FAQs

How to verify pipe thread making machine supplier reliability?

Check consistency in on-time delivery performance (target ≥95%) and response time (ideally ≤4 hours). Request evidence of quality control procedures, such as in-process inspections and final product testing. For high-value procurements, conduct third-party factory audits or request video tours to confirm production infrastructure and inventory management practices.

What is the typical MOQ and lead time?

MOQ ranges from 1 piece for entry-level handheld threaders to 5–10 sets for heavy-duty or customized models. Standard lead times are 15–30 days after deposit confirmation. Expedited production may be available for simple configurations at additional cost.

Can suppliers customize pipe thread machines?

Yes, leading suppliers offer customization of thread dimensions, motor voltage (110V/220V/380V), roller materials, control panels, and branding elements (logo, color scheme, packaging). Confirm technical feasibility through engineering drawings or prototypes prior to mass production.

Do these machines meet international standards?

Compliance must be verified per supplier. Look for CE marking, electrical safety certifications, and adherence to ISO 9001 quality systems. Request test reports for insulation resistance, overload protection, and thread accuracy (per ANSI B1.20.1 or ISO 7/1 standards) when supplying to regulated markets.

How are pipe thread making machines packaged and shipped?

Machines are typically packed in seaworthy plywood crates or reinforced cartons with foam padding. Export-ready suppliers provide FOB, CIF, or DAP shipping terms. Sea freight is standard for bulk orders; air shipping is viable for samples or urgent single-unit deliveries.