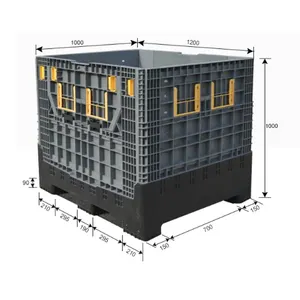

Plastic Crates Bulk

CN

CN

CN

CN

CN

CN

About plastic crates bulk

Where to Find Plastic Crates Bulk Suppliers?

China remains the global epicenter for bulk plastic crate manufacturing, with key production clusters in Shandong and Jiangsu provinces. These regions host vertically integrated facilities specializing in high-volume injection molding of HDPE and PP materials, enabling cost-efficient production at scale. Qingdao (Shandong) and Suzhou (Jiangsu) serve as primary export hubs, supported by mature logistics networks that facilitate containerized shipments to Europe, North America, and Southeast Asia.

The industrial ecosystem supports both standardized and customized solutions, with many suppliers operating automated production lines capable of monthly outputs exceeding 50,000 units. Proximity to raw material refineries reduces input costs by 10–15% compared to offshore alternatives. Buyers benefit from streamlined supply chains where design, tooling, molding, and packaging occur within consolidated zones, reducing lead times to 25–40 days for full-container orders. This infrastructure is particularly advantageous for bulk procurement of stackable, nestable, and collapsible crate variants used in agriculture, beverage distribution, and warehousing.

How to Choose Plastic Crates Bulk Suppliers?

Effective supplier selection requires systematic evaluation across three core dimensions:

Material & Structural Compliance

Confirm use of food-grade HDPE or PP resins, especially for crates intended for food transport or retail environments. For heavy-duty applications (e.g., industrial storage or palletized shipping), demand impact resistance testing data and load capacity specifications—static loads up to 2,000 kg and dynamic loads exceeding 500 kg are standard among premium models. Verify compliance with international standards such as ISO 9001 for quality management and, where applicable, FDA or EU 10/2011 for food contact safety.

Production & Customization Capacity

Assess technical capabilities through the following benchmarks:

- Minimum facility size of 3,000m² with in-house mold development

- Monthly production capacity above 30,000 units for bulk fulfillment

- Customization options including color, logo imprinting, partition integration, and dimensional adjustments

Prioritize suppliers offering sample prototypes within 7–10 days and possessing CNC machining for rapid tooling iterations.

Transaction Reliability & Export Readiness

Analyze verifiable performance metrics: on-time delivery rates above 95%, reorder rates exceeding 20%, and response times under 4 hours indicate operational stability. Confirm export experience via documented FOB/CIF shipping records and third-party trade assurance programs. Request test reports for drop tests, stack compression, and UV resistance where environmental exposure is expected.

What Are the Best Plastic Crates Bulk Suppliers?

| Company Name | Location | Verified Supplier | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Qingdao Jumbo International Trade Co., Ltd. | Shandong, CN | Multispecialty Supplier | US $500,000+ | 100% | ≤2h | 20% | Yes | 50 sets |

| Cimc Transpack Technology Co., Ltd. | Shandong, CN | Multispecialty Supplier | - | 100% | ≤4h | - | Yes | 1 set |

| Suzhou Quali New Material Technolog Co., Ltd. | Jiangsu, CN | - | US $140,000+ | 100% | ≤10h | 50% | No | 100 pieces |

| Qingdao Aistek Industry Co., Ltd. | Shandong, CN | - | US $1,000+ | 50% | ≤4h | <15% | No | 2 sets |

| Qingdao World Link Industry Co., Ltd. | Shandong, CN | - | US $50,000+ | 100% | ≤2h | <15% | No | 10 pieces |

Performance Analysis

Qingdao Jumbo International and Cimc Transpack lead in reliability and customization, with 100% on-time delivery and flexible MOQs starting from one set. Cimc’s direct access to industrial-grade materials enables robust designs suitable for intermodal logistics. Suzhou Quali stands out with a 50% reorder rate, indicating strong customer satisfaction despite limited responsiveness. In contrast, Qingdao Aistek’s 50% on-time delivery rate presents a higher fulfillment risk despite competitive pricing. Buyers seeking low-volume trials should consider Qingdao World Link, which offers entry-level MOQs from 10 pieces and fast communication cycles.

FAQs

How to verify plastic crates bulk supplier reliability?

Cross-check self-reported certifications with official databases. Request evidence of past shipments via bill of lading samples or third-party inspection reports. Evaluate product consistency through independent lab testing of wall thickness, weight tolerance, and structural integrity under load.

What is the average sampling timeline?

Standard crate samples are typically produced within 5–7 days. Custom molds may require 15–20 days for development. Air freight delivery adds 7–12 days depending on destination region.

Can suppliers ship plastic crates worldwide?

Yes, most established manufacturers manage global exports via sea freight (FCL/LCL) and air cargo. Confirm Incoterms (FOB, CIF, DDP), packaging specifications (nested vs. flat-packed), and compatibility with standard pallet configurations (e.g., EUR, ISO).

Do manufacturers provide free samples?

Sample policies vary. Some suppliers waive fees for qualified buyers committing to future bulk orders. Otherwise, expect charges covering material and handling, typically $50–$150 per unit, refundable against first-order value.

How to initiate customization requests?

Submit detailed requirements including internal dimensions, load ratings, stacking configuration, color codes (Pantone), and branding elements. Reputable suppliers respond with CAD drawings or 3D renderings within 72 hours and initiate mold production upon approval.