Polyester Button Manufacturing Process

CN

CN

CN

CN

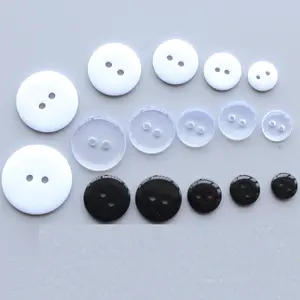

About polyester button manufacturing process

Where to Find Polyester Button Manufacturers?

China remains the global epicenter for polyester button manufacturing, with key production hubs in Guangdong, Zhejiang, and Yiwu offering vertically integrated supply chains. These regions host specialized clusters combining polymer processing, molding technology, and garment accessory finishing, enabling cost-efficient mass production. Guangzhou and Taizhou are notable for eco-friendly polyester formulations, while Yiwu excels in high-volume resin-based button output due to concentrated raw material access and logistics infrastructure.

Suppliers leverage injection molding and compression techniques to produce buttons from recycled or virgin polyester, often integrating color masterbatch systems for consistent pigmentation. Facilities typically operate automated assembly lines capable of producing 500,000–2 million units monthly per production line. The proximity of mold makers, pigment suppliers, and packaging vendors within 30–50 km reduces lead times by up to 40% compared to decentralized sourcing models. Buyers benefit from scalable production, with standard order fulfillment averaging 15–25 days post-approval.

How to Choose Polyester Button Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Material & Process Compliance

Verify use of UV-stable, non-toxic polyester resins compliant with RoHS and REACH standards, particularly for children’s apparel. Demand documentation on pigment fastness (AATCC Test Method 61) and resistance to hydrolysis under humid conditions. For recycled polyester, request proof of input traceability and certification such as GRS (Global Recycled Standard).

Production Capacity Verification

Assess core capabilities through the following indicators:

- Minimum monthly output capacity exceeding 500,000 pieces

- In-house mold design and fabrication capability (reduces tooling lead time by 7–10 days)

- Color matching precision using spectrophotometers (ΔE ≤1.5 tolerance)

- Automated sorting and defect detection systems

Cross-reference claimed capacities with actual online revenue data and reorder rates to validate scalability.

Customization & Quality Control

Confirm availability of full customization: diameter (8–30mm), thickness (1–3mm), hole configuration (2/4-hole), surface finish (gloss/matte/debossed). Require sample validation against dimensional tolerances (±0.1mm) and torque testing for shank strength. Prioritize suppliers with documented QC checkpoints at molding, coloring, and packing stages.

What Are the Leading Polyester Button Manufacturers?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Min. Order Quantity | Price Range (USD) | Customization Support |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Kunshuo International Trade Co., Ltd. | Guangdong, CN | US $170,000+ | 98% | ≤2h | 31% | 100 pcs | $0.02–0.08 | Yes (color, shape, magnet, logo, stamping) |

| Yiwu Jincong Garment Accessories Co., Ltd. | Zhejiang, CN | US $80,000+ | 96% | ≤2h | 20% | 1,000 pcs | $0.01–0.05 | Yes (color, size, logo, packaging) |

| ASIA LEI (TAIZHOU) IMPORT AND EXPORT CO.,LTD. | Taizhou, CN | US $3,000+ | 100% | ≤2h | 16% | 1,000 pcs | $0.05–0.29 | Yes (size, logo, graphic, packaging) |

| Guangzhou Xinzhuo Apparel Co., Ltd. | Guangdong, CN | US $30,000+ | 98% | ≤3h | 15% | 100 pcs | $0.03–0.19 | Limited (stock colors, basic shapes) |

| Zhejiang Longqi Science & Technology Group Wenzhou Jinghong International Trade Co., Ltd. | Zhejiang, CN | US $1,000+ | 100% | ≤4h | - | 50 pcs | $0.02–1.62 | Yes (fashion designs, solid colors) |

Performance Analysis

Guangzhou Kunshuo leads in reorder performance (31%) and responsiveness, supporting low MOQs ideal for sampling and small-batch production. Yiwu Jincong offers the most competitive pricing ($0.01/unit) but requires higher minimums (1,000+ units), making it suitable for bulk contracts. ASIA LEI and Zhejiang Longqi achieve perfect on-time delivery records, indicating robust internal scheduling despite lower sales volumes. Suppliers in Guangdong generally offer greater flexibility in customization and faster turnaround than their counterparts in Zhejiang, though at a 20–40% price premium. For eco-conscious buyers, prioritize suppliers explicitly listing recycled polyester or biodegradable resin options.

FAQs

What is the typical lead time for polyester button orders?

Standard orders take 10–18 days after sample approval. Custom molds add 7–12 days. Rush processing (50% surcharge) can reduce lead time by 3–5 days.

Do manufacturers provide free samples?

Most suppliers offer 5–10 free samples with paid shipping. Reimbursed if order exceeds 1,000 units. Custom-designed samples may incur tooling fees ($50–$150).

Can polyester buttons be made from recycled materials?

Yes. Several suppliers use post-consumer PET bottles processed into granules for button molding. Request GRS certification to verify recycled content claims.

What are common quality defects to inspect?

Check for warping, incomplete filling, color variation (ΔE >2), flash lines, and inconsistent hole alignment. Batch sampling (AQL 2.5) is recommended for orders over 10,000 units.

How are custom logos applied on polyester buttons?

Methods include hot-stamping, screen printing, laser engraving, and molded-in relief. Hot-stamping with metallic foils is most common for branding; ensure adhesion testing is performed under steam iron conditions (180°C, 10 sec).