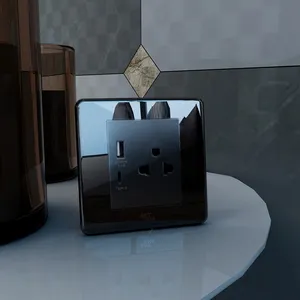

Pop Socket

Top sponsor listing

Top sponsor listing

CN

CN

About pop socket

Where to Find Pop Socket Suppliers?

China remains the central hub for pop socket manufacturing, with key production clusters concentrated in Guangdong, Zhejiang, and Jiangsu provinces. These regions host vertically integrated supply chains that streamline raw material sourcing, injection molding, surface finishing, and logistics. Dongguan and Yiwu in particular have emerged as specialized centers—Dongguan focusing on electronic-integrated models with USB charging and motorized lift mechanisms, while Yiwu dominates decorative and promotional variants using acrylic, silicone, and sublimation printing techniques.

The industrial ecosystem enables rapid prototyping and high-volume output, supported by localized access to ABS/PC plastics, adhesive gel compounds, and SMT assembly lines. Suppliers benefit from compact supplier networks where mold fabrication, plating services, and packaging providers operate within 30–50 km radii, reducing component lead times by up to 40%. This integration translates into average production cycles of 15–25 days for standard orders and scalability for bulk shipments exceeding 10,000 units.

How to Choose Pop Socket Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure product quality, compliance, and operational reliability:

Technical and Functional Compliance

Verify adherence to international electrical safety standards where applicable—particularly CE, RoHS, and FCC certifications for power-enabled models featuring USB ports or wireless charging. For mechanical pop-up sockets used in furniture or flooring installations, confirm IP ratings (e.g., IP65 for waterproofing) and load durability testing. Suppliers integrating smart functionality must provide validation of circuit protection, over-current prevention, and thermal management systems.

Production and Customization Capability

Assess technical infrastructure based on the following benchmarks:

- Minimum facility size of 2,000m² for sustained volume output

- In-house tooling and mold development teams

- Support for multi-material injection molding (ABS, PC, TPU) and advanced decoration methods (silkscreen, laser engraving, dye-sublimation)

- Customization depth including color matching (Pantone), logo embossing, packaging design, and shape variation

Cross-reference customization claims with actual product listings and client portfolios. Prioritize suppliers offering 3D renderings or physical samples within 7–10 days.

Transaction Reliability and Quality Control

Evaluate performance metrics derived from verifiable transaction histories. Target suppliers with on-time delivery rates exceeding 95% and reorder rates above 25%, indicating customer retention and fulfillment consistency. Confirm implementation of QC protocols at three stages: incoming materials, in-process inspection, and final shipment audit. Use third-party inspection services for pre-shipment verification, especially for first-time partnerships.

What Are the Best Pop Socket Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|

| Yiwu Langjia Craft Co., Ltd. | Pop Sockets (5+) | 99% | 27% | ≤3h | US $190,000+ | Color, material, size, logo, packaging, label, graphic |

| Dongguan Blue Shark Technology Co., Limited | Pop Sockets (5) | 96% | 19% | ≤2h | US $160,000+ | Socket type, charging ports, hole size, color, configuration, wireless charging, logo, dimensions, waterproofing, USB ports |

| Nantong Zeshan Electric Appliance Co., Ltd. | Plugs & Sockets (756) | 96% | 34% | ≤3h | US $30,000+ | Not specified |

| Zhongshan Gamder Electric Appliance Co., Ltd. | Wall Switches (221), Plugs & Sockets (148) | 100% | <15% | ≤5h | US $4,000+ | Color |

| Dongguan Baijie Electronic Co., Ltd. | Plugs & Sockets (152) | 50% | <15% | ≤4h | US $5,000+ | Not specified |

Performance Analysis

Yiwu Langjia stands out in the promotional segment with extensive customization capabilities and high online revenue, supported by a 99% on-time delivery rate. Its focus on acrylic-based, branded pop sockets makes it ideal for marketing campaigns and retail distribution. Dongguan Blue Shark Technology offers the broadest technical configurability, catering to OEM clients requiring integrated power solutions with USB-C or wireless charging in built-in desk or floor models. Despite lower reorder rates, its ≤2h response time and robust feature set position it well for engineering-driven buyers.

Nantong Zeshan demonstrates strong market traction with a 34% reorder rate, reflecting consistent satisfaction in the functional socket category. However, limited public data on customization depth may require direct inquiry. Zhongshan Gamder achieves perfect on-time delivery but reports minimal reorder activity and narrow customization scope, suggesting a transactional buyer profile. Dongguan Baijie presents higher risk due to a 50% on-time delivery rate despite competitive pricing, warranting enhanced oversight if selected.

FAQs

What are typical MOQs for pop socket orders?

MOQs vary by supplier and product type. Decorative models from craft-focused manufacturers start as low as 20 pieces, while electronic or built-in pop-up sockets typically require 5–10 units per order. High-volume structural components (e.g., floor-mounted outlets) may require 100+ units.

What is the average lead time for custom pop sockets?

Standard production lead time ranges from 15 to 25 days post-sample approval. For new molds or complex configurations (e.g., motorized lift systems), add 7–10 days for tooling development. Air shipping adds 5–7 days internationally; sea freight requires 25–35 days depending on destination.

Do suppliers offer free samples?

Most suppliers provide paid samples to cover material and handling costs. Sample fees typically range from $20–$100 and may be credited toward future orders. Free samples are occasionally offered for high-potential buyers with projected annual volumes exceeding 5,000 units.

Can pop sockets be customized with branding?

Yes, leading suppliers support full branding integration including logo embossing, custom colors (Pantone-matched), graphic overlays, and tailored packaging. Sublimation printing allows for full-color anime, cartoon, or promotional designs, particularly on acrylic variants.

What payment terms are common among suppliers?

Standard terms include 30% deposit with 70% balance before shipment. Established partners may accept Letters of Credit (L/C) or use escrow services for transaction security. Suppliers with platform-backed trade assurance programs often support milestone payments linked to production progress.