Pop Up Backdrop Producer

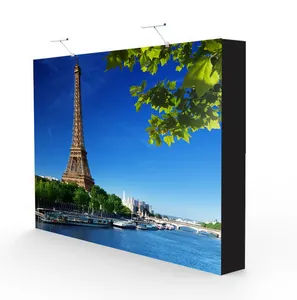

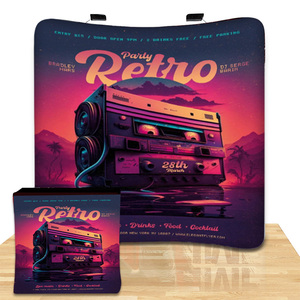

About pop up backdrop producer

Where to Find Pop Up Backdrop Producers?

China remains the global epicenter for pop up backdrop manufacturing, with key production clusters in Guangdong, Hebei, and Anhui provinces. These regions host vertically integrated facilities specializing in modular display systems, leveraging localized supply chains for aluminum extrusions, tension fabric printing, and magnetic assembly components. Foshan and Guangzhou in Guangdong province dominate high-end custom fabrication, offering advanced digital dye-sublimation printing and lightweight alloy framing. Meanwhile, Bazhou in Hebei and Hefei in Anhui focus on cost-efficient mass production, benefiting from concentrated component suppliers and lower labor costs.

The industrial ecosystem supports rapid prototyping and scalable output, with many producers operating dedicated in-house production lines for extrusion, welding, cutting, and graphic application. This integration reduces lead times to 10–25 days for standard orders and enables flexible MOQs down to one unit. Suppliers typically utilize warp-knit polyester or silicone-edge graphics mounted on aluminum frames, with modular magnetic or snap-button assembly for portability. Buyers gain access to comprehensive customization options—including size, color, branding, packaging, and structural design—across a mature network of OEM/ODM-capable manufacturers.

How to Choose Pop Up Backdrop Producers?

Effective supplier selection requires rigorous evaluation across three core areas:

Production & Customization Capability

Verify that suppliers operate their own production lines with capacity for full-cycle manufacturing—from frame extrusion to fabric printing and final assembly. Key indicators include in-house CNC machining, automated cutting tables, and large-format dye-sublimation printers. Prioritize partners advertising customization options in material (fabric type), size (standard and non-standard dimensions), logo integration, graphic design support, and modular configurations. Confirm ability to produce mockups or digital renderings before order placement.

Quality Assurance & Operational Metrics

Evaluate performance through verifiable operational data:

- On-time delivery rate exceeding 95%

- Response time under 4 hours (ideally ≤2h)

- Reorder rate above 20% indicating customer retention

- Evidence of systematic quality control protocols

Cross-reference revenue volume and product listing diversity as proxies for market validation and production stability.

Transaction Security & Export Readiness

Assess transaction safeguards such as secure payment terms, dispute resolution mechanisms, and export documentation support. Review supplier history for consistent international shipping performance. Request sample units to evaluate build quality, print fidelity, structural rigidity, and ease of assembly prior to bulk ordering. Confirm packaging durability for repeated transport and trade show use.

What Are the Best Pop Up Backdrop Producers?

| Company Name | Location | Primary Products | Customization Options | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Foshan Mingyue Exhibition Equipment Co., Ltd. | Foshan, CN | Magnetic modular backdrops, foldable pop-up booths | Color, material, size, logo, packaging, graphic design | 100% | ≤2h | US $7,000+ | 21% |

| Focus(China) Advertising Display Ltd. | Guangdong, CN | Tension fabric displays, roll-up banners, exhibition booths | Limited direct mention; broad product range suggests capability | 99% | ≤1h | US $180,000+ | 27% |

| Bazhou Boshang Exhibition And Display Equipment Co., Ltd. | Bazhou, CN | Telescopic banners, fabric pop-up booths, step-repeat backdrops | Inferred from product types; limited explicit detail | 94% | ≤4h | US $40,000+ | 22% |

| Guangzhou Haina Show Exhibition Co., Ltd. | Guangzhou, CN | Tension fabric walls, popup stands, LED-integrated displays | Extensive: color, fabric, frame, size, shape, lighting, media integration | 100% | ≤2h | US $1,100,000+ | 17% |

| Anhui Better Advertising Production Co., Ltd. | Anhui, CN | Premium pop-up booths, exhibition backdrops, tension fabric systems | Inferred; high pricing suggests value-added features | 81% | ≤8h | US $160,000+ | 33% |

Performance Analysis

Foshan Mingyue and Guangzhou Haina stand out for perfect on-time delivery records and strong customization depth, supported by advanced production infrastructure. Focus(China) demonstrates superior responsiveness (≤1h) and high reorder rates, reflecting reliable service execution. Guangzhou Haina leads in revenue volume, indicating extensive export experience and scalability. While Anhui Better Advertising reports the highest reorder rate (33%), its lower on-time delivery performance (81%) presents a risk factor requiring due diligence. Bazhou Boshang offers competitive entry-level pricing but slower response times, typical of northern China’s more price-driven cluster.

FAQs

What materials are commonly used in pop up backdrops?

Most suppliers use 200–300gsm warp-knit polyester fabric with dye-sublimated graphics for vibrant, wrinkle-resistant finishes. Frames are typically constructed from anodized aluminum (6063-T5 grade) for strength-to-weight efficiency. Magnetic, snap, or bungee cord attachment systems enable quick setup.

What is the typical MOQ and lead time?

MOQs are frequently set at 1 piece, especially for custom designs. Standard lead times range from 10 to 20 days after artwork approval. Rush production may be available for urgent orders, subject to supplier capacity.

Can I request fully customized designs?

Yes, most top-tier producers offer full customization in dimensions, shape (curved, arched, multi-panel), frame color, fabric type, lighting integration (LED strips), and packaging. Digital mockups and sample prototypes are often provided for validation.

Do these suppliers provide printing services?

Virtually all listed suppliers include in-house digital printing capabilities using dye-sublimation technology, ensuring high-resolution, fade-resistant graphics tailored to client specifications.

How should I verify product quality before ordering?

Request physical or digital samples to assess fabric tension, print clarity, weld integrity, and hardware smoothness. Conduct factory audits via video tour to confirm production line ownership and quality control checkpoints. Review third-party transaction histories where available.