Potential Suppliers Of Raw Materials Examples

About potential suppliers of raw materials examples

Where to Find Potential Suppliers of Raw Materials?

Global sourcing of raw materials is increasingly centralized in industrial hubs across China, where integrated supply chains and specialized manufacturing zones enable competitive pricing and scalable production. Regions such as Hebei, Xinjiang, and Shenzhen have emerged as key centers for bulk chemical, plastic, rubber, and cosmetic ingredient suppliers. These clusters benefit from proximity to ports, refineries, and polymer processing facilities, reducing logistics overhead by 15–25% compared to decentralized markets.

The concentration of technical expertise and vertically aligned production—spanning extraction, refinement, and formulation—allows for rapid turnaround on both standard and customized orders. Buyers gain access to diversified material portfolios, including petrochemical derivatives, recycled polymers, conductive elastomers, and active cosmetic ingredients. Typical advantages include MOQ flexibility (from 1 kg to 20+ tons), consistent batch quality, and faster sampling cycles (7–14 days for most chemical and plastic raw materials).

How to Evaluate Raw Materials Suppliers?

Effective supplier assessment requires a structured approach focused on compliance, operational capacity, and transaction reliability.

Quality & Compliance Verification

Confirm adherence to international standards such as ISO 9001 for quality management. For cosmetics and healthcare ingredients, verify CAS numbers, purity levels (e.g., ≥98%), and compliance with regional regulations (e.g., EU REACH, FDA). Material Safety Data Sheets (MSDS) and third-party test reports should be available upon request.

Production & Technical Capacity

Assess infrastructure through verifiable metrics:

- Minimum facility size supporting continuous output (e.g., ≥5,000m² for polymer producers)

- In-house R&D or formulation capabilities for custom blends

- Processing technologies: extrusion, compounding, distillation, or spray drying

Cross-reference response times (target ≤6 hours) and reorder rates (ideally >20%) as indicators of service efficiency and customer satisfaction.

Procurement Safeguards

Utilize secure payment methods with escrow functionality to mitigate risk. Prioritize suppliers with documented export experience and transparent order tracking. Request samples before bulk ordering to validate material specifications, packaging integrity, and labeling accuracy. Analyze online transaction volume (e.g., US $130,000+ annual revenue) as a proxy for market validation.

What Are the Leading Raw Materials Suppliers?

| Company Name | Main Products | Price Range (USD) | MOQ | Response Time | On-Time Delivery | Reorder Rate | Online Revenue | Specialization |

|---|---|---|---|---|---|---|---|---|

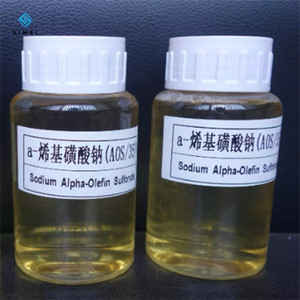

| Yifan Industrial Co., LTD | Daily Chemicals, SLES, Alcohol, Pigments | $0.50–1.00 | 1 kg | ≤10h | - | - | - | Surfactants & Sanitizer Components |

| Shenzhen Brilliance Rubber & Plastic Material Co., Ltd. | Silicone Rubber, Conductive Elastomers, Unvulcanized Rubber | $1.50–300.00 | 1 kg | ≤6h | 100% | 40% | US $280,000+ | Specialty Rubber & Conductive Materials |

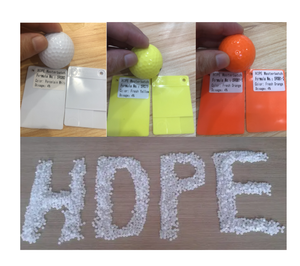

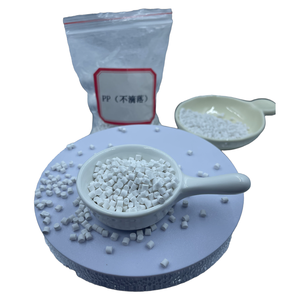

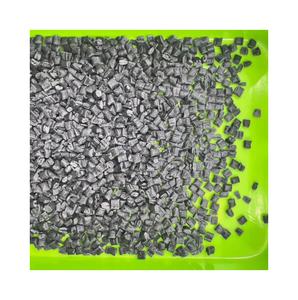

| HEBEI SHENGHUA INDUSTRY CO LTD | PP, HDPE, LDPE, ABS, Masterbatch | $580–1,258 | 1–20 tons | ≤4h | - | - | - | Plastic Resins & Recycled Polymers |

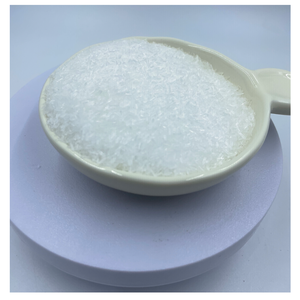

| Xinjiang mingsheng international trade co ltd | SINOPEC Plastics, HIPS, SEBS, Dishwashing Liquids | $0.50–10,737.30 | 1 kg – 1 metric ton | ≤13h | - | - | - | Polymer Compounds & Daily Chemicals |

| Xi'an Sequoia Bioengineering Technology Co., Ltd | Keratin, N-Acetyl-L, Plant Extracts, Cosmetic Actives | $10–38 | 1 kg / bag | ≤1h | 99% | 24% | US $130,000+ | Bioactive Ingredients & Custom Formulations |

Performance Analysis

Shenzhen Brilliance Rubber stands out with a verified 100% on-time delivery rate and high reorder frequency (40%), indicating strong operational consistency in specialty rubber supply. Xi'an Sequoia leads in responsiveness (≤1h) and serves niche biotech and cosmetic markets with traceable, high-purity actives. HEBEI SHENGHUA offers large-volume plastic resins at competitive prices, ideal for injection molding and extrusion applications requiring 20-ton minimums. Yifan Industrial and Xinjiang Mingsheng provide flexible entry points for small-scale formulators with 1kg MOQs, though limited delivery performance data suggests due diligence is required. Suppliers with documented online revenues (e.g., >US $100,000) demonstrate market traction and export readiness.

FAQs

How to verify raw materials supplier credibility?

Cross-check provided certifications with issuing bodies. Request batch-specific test reports, MSDS, and proof of export history. Evaluate communication professionalism and technical detail in responses as indirect quality indicators.

What is the typical lead time for raw material shipments?

Standard orders ship within 7–15 days after confirmation. Custom formulations may require 14–21 days for production. Air freight delivers samples in 5–10 days globally; sea freight takes 20–35 days for containerized bulk orders.

Can suppliers accommodate custom formulations?

Yes, many offer OEM/ODM services for color masterbatches, surfactant blends, and bioactive compounds. Provide exact specifications (CAS, concentration, solubility) to receive accurate proposals. Minimum development fees may apply for new formulations.

Are samples available for testing?

Most suppliers provide samples, often free for qualified buyers or refundable against future orders. Expect shipping charges unless FOB terms are negotiated. Sample sizes typically range from 100g to 1kg for chemicals and powders.

What packaging options are standard?

Liquids are shipped in HDPE drums (25–200L); powders in multi-layer kraft bags (25kg); pellets in woven polypropylene sacks (25kg). Custom packaging with labeling, barcodes, or branding is widely supported, especially among multispecialty suppliers.