Process Automation Systems

About process automation systems

Where to Find Process Automation Systems Suppliers?

China remains a central hub for process automation systems manufacturing, with specialized industrial clusters in Guangdong, Hubei, and Fujian provinces driving innovation and cost efficiency. These regions host vertically integrated supply chains that combine electronic component sourcing, control system assembly, and software integration under one ecosystem. Guangdong’s Shenzhen and Huizhou zones are particularly notable for advanced motion control and industrial PC production, while Wuhan in Hubei has emerged as a center for PLC (Programmable Logic Controller) modules and field devices.

The concentration of technical talent and supporting infrastructure enables suppliers to deliver both hardware-based automation platforms and software-driven solutions at competitive price points. Regional advantages include proximity to semiconductor distributors, streamlined logistics for export shipments, and access to contract engineering services for custom programming. Buyers benefit from shorter development cycles—typical lead times range from 15–30 days for standard configurations—with scalability for batch orders exceeding 1,000 units. Localized production reduces overall costs by 20–35% compared to Western alternatives, especially for modular systems such as track-guided assembly lines or cloud-connected ERP-integrated controls.

How to Choose Process Automation Systems Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Assessment

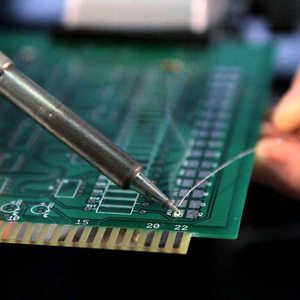

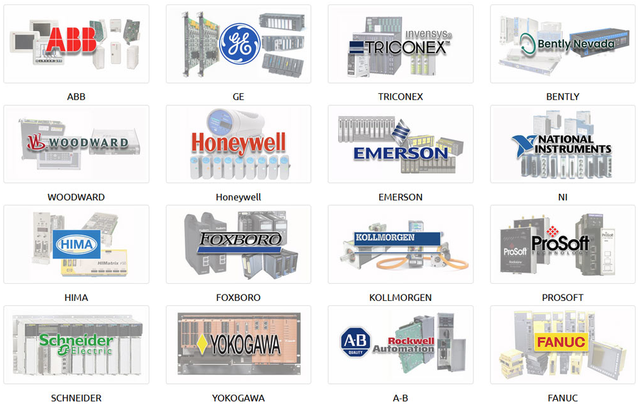

Confirm supplier expertise in core automation domains: PLC/PAC controllers, human-machine interfaces (HMIs), industrial networking, and real-time data processing. For hardware-focused systems, verify compatibility with established industrial protocols (e.g., PROFINET, Modbus). Software-centric vendors should demonstrate experience in cloud ERP integration, digital workflow modeling, and cybersecurity frameworks. While formal ISO 9001 certification is not universally listed, prioritize suppliers who document quality management practices and provide testing reports for critical components.

Production and Integration Capacity

Evaluate the breadth of offerings and internal production depth:

- Suppliers with over 1,000 product listings often indicate mature R&D and inventory systems

- In-house design teams enable customization of mechanical guides, conveyor layouts, or software dashboards

- Integrated facilities capable of producing full-system assemblies—from linear rails to control cabinets—reduce third-party dependencies

Cross-reference response time (target ≤2 hours) and on-time delivery rates (ideal ≥95%) as indicators of operational reliability.

Sourcing Risk Mitigation

Utilize secure payment mechanisms and pre-shipment verification processes. Request product samples to validate performance against functional specifications, particularly for programmable modules or automated assembly lines. For software-based automation tools, conduct live demos or trial deployments to assess usability and integration latency. Review online transaction volume where available, as higher revenue thresholds (e.g., US $30,000+) correlate with sustained market presence and customer retention.

What Are the Best Process Automation Systems Suppliers?

| Company Name | Main Products | Product Listings | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Bimeigao Intelligent System Technology Co., Ltd. | Laser Marking Machines, Testing Equipment | 4,268+ | 100% | ≤1h | - | $30,000+ | 1 piece/box | $2,390–$3,899 |

| Huizhou Zhenji Automation Technology Co., Ltd. | Assembly Line, Linear Guides | 97+ | 100% | ≤1h | 50% | $10,000+ | 1 set | $158–$4,500 |

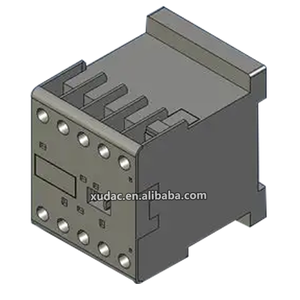

| Wuhan Hantuo Automation System Co., Ltd. | PLC, PAC & Controllers | 1,105+ | 100% | ≤5h | <15% | $3,000+ | 1 piece | $8–$5,215 |

| Shantou Sikinta Automation Equipment Co., Ltd. | Process Automation Hardware | 5+ | 100% | ≤2h | 50% | $60,000+ | 1 piece | $150–$315 |

| KAEM SOFTWARES PRIVATE LIMITED | Automation Software, ERP Systems | 1,267+ | - | ≤2h | - | $8,000+ | 1–2 units | $95–$395 |

Performance Analysis

Guangzhou Bimeigao stands out for high-value integrated systems, offering end-to-end automated assembly lines with pricing aligned to industrial-grade durability. Huizhou Zhenji provides flexible track and guide solutions ideal for modular production setups, backed by strong reorder metrics and rapid responsiveness. Wuhan Hantuo specializes in genuine PLC modules, including high-cost CPU units, though its lower reorder rate suggests room for improvement in post-sale engagement. Shantou Sikinta delivers competitively priced B&R X20-compatible components with robust transaction performance, indicating reliability for spare part procurement. KAEM SOFTWARES focuses exclusively on digital process automation and cloud ERP tools, serving buyers prioritizing low-code workflows over physical hardware. Suppliers with response times under two hours and verified on-time delivery records present lower coordination risk for urgent or complex deployments.

FAQs

How to verify process automation system supplier reliability?

Assess consistency in delivery performance, response speed, and transaction volume. Request technical documentation such as I/O specifications, firmware versions, and network topology diagrams. For hardware, confirm origin authenticity (e.g., original vs. compatible modules); for software, evaluate update frequency and API accessibility. Third-party trade assurance programs can help validate order fulfillment history.

What is the typical minimum order quantity (MOQ)?

Most suppliers list an MOQ of 1 unit for individual components like PLCs or software licenses. For complete systems such as automated assembly lines or multi-axis guide rails, the MOQ is typically 1 set. Bulk pricing may apply for orders exceeding 10 units, depending on the complexity and customization level.

Can suppliers customize automation systems?

Yes, many suppliers offer configuration services for mechanical layouts, control logic programming, and software interface design. Full customization—such as integrating barcode scanning into an existing line or adapting ERP workflows to specific industries—is feasible with vendors possessing dedicated engineering resources. Lead time for customized solutions ranges from 20–45 days based on scope.

Do suppliers provide samples?

Sample availability varies. Some vendors offer paid samples for testing, particularly for high-value items like CPUs or laser marking systems. Software providers may grant time-limited demo access. Sample costs are typically non-refundable unless followed by a bulk purchase.

What are common shipping methods and timelines?

International shipments are commonly dispatched via express courier (DHL, FedEx) for small parcels (3–7 days) or air freight for larger sets (7–14 days). Sea freight is recommended for full system installations requiring crates or pallets, with transit times of 20–35 days depending on destination port and customs clearance procedures.