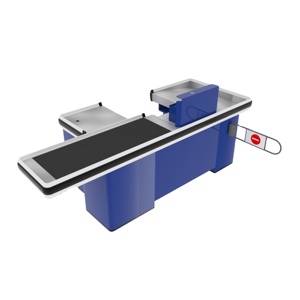

Processing Checkout Counter Factory

1/22

1/22

1/21

1/21

CN

CN

1/15

1/15

1/34

1/34

HK

HK

1/18

1/18

1/13

1/13

1/21

1/21

1/36

1/36

1/19

1/19

CN

CN

1/26

1/26

1/24

1/24

CN

CN

1/19

1/19

CN

CN

About processing checkout counter factory

Where to Find Processing Checkout Counter Suppliers?

China remains the central hub for manufacturing processing checkout counters, with key industrial clusters located in Shandong, Zhejiang, and Guangdong provinces. These regions host vertically integrated factories specializing in metal fabrication, conveyor integration, and point-of-sale (POS) furniture production. Qingdao and Zhucheng in Shandong are known for stainless steel and durable metal-based counter systems, leveraging proximity to raw material suppliers to reduce input costs by 15–20%. Yiwu and Guangzhou serve as commercial logistics centers, offering rapid prototyping and export-ready packaging solutions tailored for international retail infrastructure projects.

The concentration of component manufacturers—ranging from belt drive systems to anti-theft sensor integrations—enables streamlined production cycles. Factories within these zones typically operate full in-house processing lines, including laser cutting, CNC bending, powder coating, and final assembly. This integration supports lead times averaging 20–35 days for bulk orders, with customization capabilities covering structural dimensions, surface materials, color finishes, and embedded technology modules such as barcode scanners or payment terminals.

How to Choose Processing Checkout Counter Suppliers?

Procurement decisions should be guided by verified operational metrics and technical competencies:

Production Infrastructure Verification

Prioritize suppliers with documented own production lines and physical facility control. Key indicators include minimum factory areas exceeding 3,000m², dedicated welding and finishing stations, and in-house design teams capable of translating layout schematics into functional units. Confirm ownership of tooling equipment for conveyor belts and modular counter joints to ensure scalability.

Quality Assurance Protocols

Evaluate compliance with international quality benchmarks:

- ISO 9001 certification for standardized manufacturing processes

- Material traceability documentation for stainless steel (e.g., SUS304) or engineered wood components

- Surface treatment standards such as electrostatic powder coating or anodizing for wear resistance

Cross-reference on-time delivery rates (target ≥95%) and reorder frequency to assess consistency in output quality and service reliability.

Customization & Transaction Security

Require clear specifications on modifiable parameters: counter length (standard range 1.2–3m), height adjustability, conveyor speed settings, and branding options (logo engraving, color coding). Use secure transaction mechanisms with milestone-based payments, particularly for high-value custom builds. Validate supplier claims through product-specific videos or third-party inspection services before shipment.

What Are the Best Processing Checkout Counter Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Customization Scope |

|---|---|---|---|---|---|---|---|---|

| Qingdao Jiachenxin Metal Products Co., Ltd. | Shandong, CN | Custom Manufacturer | US $450,000+ | 100% | ≤3h | <15% | 3 pieces | Layout, color, material, size, logo, packaging, graphic |

| Zhucheng City Chaoyu Goods Shelf Co., Ltd. | Shandong, CN | - | US $760,000+ | 100% | ≤2h | 26% | 1 set | Color, material, size, design, weight, style, dimensions |

| Yiwu Hotter Commercial Equipment Co., Ltd. | Zhejiang, CN | Custom Manufacturer | US $350,000+ | 100% | ≤6h | 42% | 1 piece | Color, material, size, logo, packaging, label, graphic |

| Guangzhou Bull Leader Shelves Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $120,000+ | 100% | ≤3h | 60% | 10 sets | Fixture, color, material, size, logo, packaging, compatibility, graphic |

| HIGHBRIGHT GROUP LIMITED | Guangdong, CN | Custom Manufacturer | US $50,000+ | 88% | ≤2h | <15% | 1 piece | Color, material, size, length, logo |

Performance Analysis

Zhucheng City Chaoyu leads in responsiveness and transaction volume, with sub-2-hour reply times and a strong online revenue track record, indicating robust order handling capacity. Yiwu Hotter demonstrates high customer retention (42% reorder rate), suggesting consistent satisfaction with product quality and post-sale coordination. Guangzhou Bull Leader, despite lower online revenue, shows the highest reorder rate (60%), reflecting niche reliability in large-volume retail fit-outs. HIGHBRIGHT’s 88% on-time delivery rate presents a deviation risk for time-sensitive deployments, warranting closer logistics oversight. All top-tier suppliers support single-unit sampling, enabling cost-effective validation prior to mass procurement.

FAQs

How to verify processing checkout counter supplier reliability?

Confirm ownership of production facilities through video audits or third-party inspection reports. Check consistency in material sourcing, especially for load-bearing components like steel frames or conveyor rollers. Analyze historical shipping records and customer feedback focusing on structural durability and dimensional accuracy.

What is the typical sampling timeline?

Standard sample production takes 10–20 days, depending on complexity. Units with electric conveyors or custom surface treatments may require up to 30 days. Air freight adds 5–10 days for international delivery. Some suppliers offer reduced or waived sample fees upon confirmation of future bulk orders.

Can suppliers accommodate mixed-material constructions?

Yes, leading manufacturers support hybrid builds combining stainless steel bases with wooden worktops or laminated surfaces. Material compatibility must be specified during design approval to ensure structural integrity and long-term joint stability under continuous use.

Do suppliers provide global shipping and installation support?

Most suppliers arrange FOB or CIF shipping globally and partner with local freight forwarders. While installation is typically not included, technical drawings, assembly manuals, and video guides are provided. For complex multi-counter setups, on-site supervision can be negotiated at additional cost.

What are common MOQ and pricing ranges?

Minimum order quantities vary from 1 piece for premium models to 10–20 sets for economy lines. Prices range from $58 for basic non-conveyor units to over $1,800 for fully customized stainless steel configurations with dual-belt systems and integrated electronics.