Production Monitoring System Excel

About production monitoring system excel

Where to Find Production Monitoring System Excel Suppliers?

China remains a central hub for industrial monitoring system manufacturing, with key suppliers concentrated in the Yangtze River Delta and Pearl River Delta regions. Nanjing, Shenzhen, and Xiamen host specialized electronics and automation clusters that integrate sensor technology, data acquisition modules, and software interfaces into scalable production monitoring solutions. These zones benefit from mature supply chains for PCBs, microcontrollers, and IoT components, enabling rapid prototyping and assembly.

Suppliers in these regions offer integrated capabilities—from firmware development to hardware calibration—supporting systems compatible with Excel-based reporting through CSV export, ODBC connectivity, or API integration. The proximity of component suppliers and contract manufacturers reduces lead times by 20–30% compared to offshore alternatives. Buyers gain access to vertically aligned operations where enclosure fabrication, circuit board sourcing, and final testing occur within tightly coordinated networks, ensuring consistency in batch production and customization scalability.

How to Choose Production Monitoring System Excel Suppliers?

Procurement decisions should be guided by technical validation, operational reliability, and post-sale support readiness:

Technical Compatibility Verification

Confirm that systems support structured data export to Excel via standard formats (CSV, XLSX) or real-time synchronization using Modbus, MQTT, or OPC UA protocols. Evaluate whether the supplier provides pre-configured templates or macros for automated dashboard generation. For legacy factory environments, ensure compatibility with existing SCADA or PLC infrastructure.

Production and Quality Assurance Standards

Assess supplier adherence to recognized quality frameworks such as ISO 9001. Prioritize vendors offering CE, RoHS, or FCC certifications, particularly for deployment in EU or North American facilities. Request documentation on environmental testing (temperature, humidity, EMI resistance) and mean time between failures (MTBF) for critical components like data loggers and communication gateways.

Operational Performance Metrics

Analyze delivery reliability and responsiveness using verifiable benchmarks:

- On-time delivery rate exceeding 95%

- Average response time under 2 hours

- Reorder rate above 20% indicating customer retention

Cross-reference these metrics with online transaction volume to assess order fulfillment capacity and market trust.

What Are the Best Production Monitoring System Excel Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Online Revenue | Min. Order Value | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Nanjing Zhuneng Electric Co., Ltd. | Jiangsu, CN | Energy Management, SCADA Systems | Color, material, size, logo, packaging, graphic | 100% | ≤2h | US $10,000+ | $511/set | <15% |

| Xiamen Luhengpeng Network Technology Co., Ltd. | Fujian, CN | PLC, PAC, Dedicated Controllers | Limited (standard models) | 96% | ≤1h | US $80,000+ | $40/piece | 40% |

| Huato System (Shenzhen) Co., Ltd. | Guangdong, CN | Temperature Instruments, Data Loggers | Basic configuration options | 88% | ≤3h | US $20,000+ | $139/unit | <15% |

| Shenzhen Safewill Technology Co., Ltd. | Guangdong, CN | Air Quality, Gas Analyzers, Weather Stations | Limited branding and specification tweaks | 100% | ≤2h | US $310,000+ | $1,755/set | 22% |

| Henan Compere Smart Technology Co., Ltd. | Henan, CN | IOT Meters, Power Monitoring Systems | Extensive: CT size, protocol, relay, WiFi, RS485, energy management interface | 96% | ≤3h | US $110,000+ | $30/set (100 sets MOQ) | 17% |

Performance Analysis

Xiamen Luhengpeng stands out with a 40% reorder rate and sub-hour response time, indicating strong customer satisfaction in automation component supply. Shenzhen Safewill and Nanjing Zhuneng achieve perfect on-time delivery records, supported by robust logistics execution despite higher price points. Henan Compere offers the most comprehensive customization portfolio, ideal for integrators requiring tailored communication protocols and meter configurations. While Huato System provides competitive entry-level pricing, its lower on-time delivery rate warrants closer shipment monitoring. Suppliers with revenues exceeding US $100,000 demonstrate consistent order throughput and infrastructure stability suitable for mid-to-large volume procurement.

FAQs

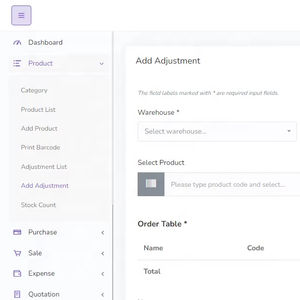

Do production monitoring systems support direct Excel integration?

Most systems do not interface directly with Excel in real time but support periodic data export via USB, SD card, or network output in CSV/XLSX formats. Some advanced models include built-in scripting or ODBC drivers for semi-automated reporting. Confirm file structure compatibility and update frequency with the supplier before integration planning.

What is the typical minimum order quantity (MOQ)?

MOQ varies by supplier and model. Entry-level data loggers may require only 1–3 units, while customized smart meter arrays or multi-node monitoring systems often have MOQs of 5–100 sets. High-volume buyers can negotiate reduced or waived MOQs based on annual purchase commitments.

How long does sample production take?

Standard samples are typically shipped within 7–15 days. Custom-configured units with specific sensor inputs, communication protocols, or enclosure materials require 20–30 days for development and testing. Expedited processing may be available for an additional fee.

Can suppliers provide OEM/ODM services?

Yes, several suppliers offer OEM labeling, custom firmware, and enclosure modifications. Nanjing Zhuneng and Henan Compere explicitly list logo, packaging, and graphical interface customization. Technical drawings and functional specifications must be submitted prior to tooling setup.

What are common payment and logistics terms?

Common payment methods include T/T, L/C, and platform-based escrow. FOB terms are standard; CIF is available upon request. Most suppliers partner with express carriers (DHL, FedEx) for samples and sea freight for bulk orders. Lead time averages 25–35 days post-payment clearance, depending on customization level.