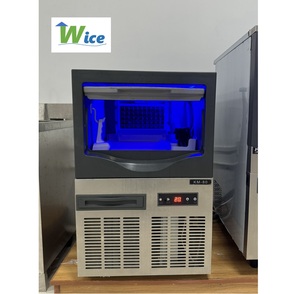

Professional Ice Cube Maker

About professional ice cube maker

Where to Find Professional Ice Cube Maker Suppliers?

China remains the global hub for professional ice cube maker manufacturing, with key production clusters in Shanghai, Guangzhou, and Zhengzhou driving innovation and scale. These regions host vertically integrated facilities that combine advanced refrigeration engineering, stainless steel fabrication, and automated control systems under one roof. Shanghai and Guangdong-based suppliers benefit from proximity to port infrastructure, enabling efficient export logistics, while Henan’s machinery-focused ecosystem supports cost-effective component sourcing and rapid prototyping.

The industrial concentration allows for streamlined production cycles, with many manufacturers operating full-process lines from mold casting to final assembly. This integration reduces lead times—typically 25–40 days for standard units—and enables scalable output ranging from compact 40kg/day models to industrial systems producing up to 2 tons daily. Buyers gain access to a mature supply chain where compressors, condensers, and food-grade water systems are sourced from certified regional vendors, ensuring consistent quality and compliance readiness.

How to Choose Professional Ice Cube Maker Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international safety and performance standards. Look for evidence of CE or ISO 9001 certification as baseline indicators of quality management. For commercial deployment in North America or Europe, confirm electrical compatibility (110V/220V), use of environmentally compliant refrigerants (e.g., R404A, R134a), and NSF-equivalent sanitation design—particularly critical for foodservice applications.

Production Capability Assessment

Evaluate core manufacturing competencies through verifiable metrics:

- Facility size and automation level indicating scalability

- In-house compressor integration and cooling system testing protocols

- Customization capacity for ice cube size, shape (full cube, half cube, crescent), and daily output (40kg to 2,000kg)

- On-time delivery rates exceeding 97% as a proxy for operational reliability

Cross-reference product listings with available customization tags such as material grade (e.g., SUS304 stainless steel), cooling method (air/water-cooled), and control panel type to assess technical flexibility.

Transaction Risk Mitigation

Prioritize suppliers with transparent order histories and responsive communication. Analyze response times (ideally ≤2 hours) and reorder rates as behavioral proxies for customer satisfaction. Utilize secure payment mechanisms and request pre-shipment inspection reports. Prototype sampling is strongly advised—benchmark ice clarity, cycle consistency, and energy consumption before committing to bulk orders.

What Are the Best Professional Ice Cube Maker Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Product Range (Capacity) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shanghai Tolcat Industrial Co., Ltd. | Shanghai, CN | Ice Machines (374) | US $300,000+ | 99% | ≤2h | 20% | 100–2,000kg/day | Limited |

| Nanning Nanyuanfang Refrigeration Equipment Co., Ltd. | Guangxi, CN | Ice Machines (N/A) | US $760,000+ | 99% | ≤5h | 18% | 40–1,000kg/day | High (shape, voltage, refrigerant, packaging) |

| Zhengzhou Yize Machinery Co., Ltd. | Henan, CN | Ice Machines (N/A) | US $450,000+ | 98% | ≤2h | 32% | 500–2,000kg/day | Medium (color, logo, size, packaging) |

| Guangzhou Anhe Catering Equipment Co., Ltd. | Guangdong, CN | Ice Machines (N/A) | US $870,000+ | 100% | ≤4h | 30% | 250–1,000kg/day | High (cooling method, motor power, controller, storage capacity) |

| Foshan Fomax Technology Co., Ltd. | Guangdong, CN | Ice Machines (239) | US $20,000+ | 90% | ≤2h | <15% | 60–1,200kg/day | Low |

Performance Analysis

Guangzhou Anhe stands out with a perfect on-time delivery record and extensive customization capabilities, making it a strong candidate for buyers requiring tailored configurations in air-cooled or high-capacity systems. Zhengzhou Yize demonstrates high customer retention (32% reorder rate), suggesting reliable post-sale support and consistent unit performance. Nanning Nanyuanfang offers broad technical configurability, including voltage and refrigerant options, ideal for international deployments with varying grid and environmental regulations. While Foshan Fomax responds quickly, its lower reorder rate and limited historical revenue suggest a smaller operational footprint, suitable for low-volume or trial procurement. Shanghai Tolcat provides mid-range capacity solutions with solid fulfillment metrics but fewer customization levers.

FAQs

What is the typical MOQ for professional ice cube makers?

Minimum Order Quantities vary by supplier and model. Most manufacturers list MOQs at 1 unit for standard machines, though some require 1 set or 2 units for promotional pricing. High-capacity industrial units may have higher thresholds based on shipping volume.

What are common lead times for production and delivery?

Standard units typically ship within 25–35 days after order confirmation. Customized models may require 35–45 days depending on complexity. Add 10–25 days for international sea freight based on destination region.

Can suppliers customize ice cube size and machine specifications?

Yes, many suppliers offer customization for cube dimensions, daily output, voltage (110V/220V), cooling type (air/water), and control interfaces. Advanced options include logo printing, color finishes, and integrated storage bins. Confirm feasibility via technical documentation or prototype validation.

Do these machines comply with food safety standards?

While explicit certifications are not listed, reputable suppliers use food-grade stainless steel (SUS304) and sealed water systems to prevent contamination. Buyers should request material compliance statements and verify internal surface finishes meet hygienic design principles for commercial kitchens.

How to evaluate supplier reliability without onsite audits?

Analyze on-time delivery rates, reorder frequency, and response speed as digital proxies for reliability. Request product videos, test reports, or third-party inspection records. Engage in detailed technical dialogue to assess engineering depth and after-sales capability before scaling orders.