Prototype And Production

Top sponsor listing

Top sponsor listing

HK

HK

1/3

1/3

1/16

1/16

1/24

1/24

1/8

1/8

1/12

1/12

1/26

1/26

About prototype and production

Where to Find Prototype and Production Suppliers?

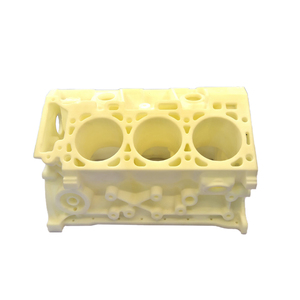

China's advanced manufacturing ecosystem offers a dense network of prototype and production service providers, with key clusters concentrated in Guangdong Province—particularly in Dongguan, Huizhou, and Shenzhen. These regions host vertically integrated facilities combining CNC machining, 3D printing, sheet metal fabrication, and injection molding under one roof, enabling seamless transition from concept validation to volume production. Proximity to material suppliers and logistics hubs reduces component lead times by up to 40% compared to offshore alternatives.

The industrial maturity in this region supports both rapid prototyping (1–5 day turnaround for basic models) and scalable batch production, with many suppliers maintaining dual-track workflows optimized for low-volume customization and high-volume repeatability. Buyers benefit from localized supply chains that cut material costs by 15–25%, while digital quoting systems streamline RFQ processing within 2–8 hours across verified manufacturers.

How to Choose Prototype and Production Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm access to multi-axis CNC machines, SLA/SLS/FFF 3D printing, and precision tooling equipment. For functional prototypes, validate compatibility with engineering-grade materials such as ABS, nylon, magnesium, aluminum, and transparent acrylics. Suppliers should support GD&T (Geometric Dimensioning and Tolerancing) and achieve tolerances down to ±0.005mm for machined parts.

Production Infrastructure Assessment

Evaluate the following benchmarks:

- Facilities equipped with ISO-classified clean rooms or climate-controlled workspaces for sensitive processes

- In-house design and engineering teams capable of interpreting 2D/3D CAD drawings, STL files, and BOMs

- Material certification documentation (e.g., RoHS, REACH compliance) for regulated industries

Cross-reference response time metrics (target ≤5 hours) and on-time delivery performance (ideal ≥98%) to assess operational reliability.

Customization & Scalability Validation

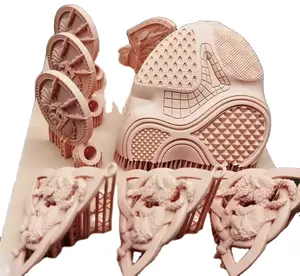

Ensure suppliers offer configurable options including color, surface finish (anodizing, powder coating, polishing), labeling, packaging, and logo integration. Assess reorder rate data—suppliers exceeding 20% indicate strong customer retention and process consistency. Prioritize partners offering DFM (Design for Manufacturing) feedback prior to production kickoff.

Transaction Risk Mitigation

Utilize secure payment frameworks with milestone-based releases tied to prototype approval and pre-shipment inspection. Request sample units before full commitment, especially for first-time engagements. Verify traceability through documented quality control checkpoints, including first-article inspection reports and final product testing protocols.

What Are the Best Prototype and Production Suppliers?

| Company Name | Main Services | Customization Options | On-Time Delivery | Response Time | Reorder Rate | Min. Order Quantity | Price Range (USD) | Verified Type |

|---|---|---|---|---|---|---|---|---|

| Huizhou Jiyan Hardware Co., Ltd. | Machining, Sheet Metal, Casting, Moulds | Size, material, logo, packaging, graphics | 100% | ≤2h | 16% | 1 piece | $0.10–$30 | Custom Manufacturer |

| Dongguan Yyi Technology Co., Ltd. | 3D Printing, Machining | Multi-color, custom geometry, small lot | 100% | ≤3h | 58% | 1 piece | $1.29–$6.90 | - |

| Industrial Man Manufacturing Co., Limited | CNC Machining, Injection Molding | Color, material, casting, packaging | 100% | ≤5h | 20% | 1 piece | $0.10–$30 | Custom Manufacturer |

| Money Generator Technology Limited | 3D Printing, Toy & Gift Modeling | Color, size, logo, graphic design | 98% | ≤3h | <15% | 50 pieces | $0.60–$3.60 | Multispecialty Supplier |

| Guangdong Fohan Technology Co., Ltd. | 3D Printing, Machining, Moulds | Wearables, action figures, textures | 86% | ≤8h | 60% | 1 piece | $0.70–$10 | - |

Performance Analysis

Dongguan Yyi Technology stands out with a 58% reorder rate and sub-3-hour response time, indicating consistent output quality and responsive client management. Huizhou Jiyan and Industrial Man deliver perfect on-time performance and support single-piece MOQs across diverse materials, ideal for early-stage development. Money Generator Technology caters to niche consumer applications like toys and gifts but imposes higher minimums (50–100 pcs), reflecting its focus on small-batch commercial runs. Guangdong Fohan shows high customer loyalty (60% reorder rate), though its 86% on-time delivery suggests potential bottlenecks during peak demand. Buyers requiring strict timeline adherence should prioritize suppliers with documented project management systems and real-time tracking.

FAQs

How to verify prototype and production supplier reliability?

Request evidence of internal quality control procedures, including first-article inspections, dimensional reports, and material test certificates. Validate claims through transaction history analysis, focusing on delivery consistency and dispute resolution outcomes. Video audits of workshop floors provide additional transparency into workflow organization.

What is the typical lead time for prototypes?

Rapid prototypes are typically delivered within 1–5 business days depending on complexity and technology used. CNC-machined parts average 3–5 days, while multi-color 3D printed models take 2–4 days. Add 7–10 days for international air shipping.

Do suppliers support full production scaling after prototyping?

Yes, most integrated manufacturers offer end-to-end services from proof-of-concept to mass production. Confirm capacity for injection molding tooling, automated assembly lines, and packaging automation when planning volume transitions above 1,000 units.

Are samples available before bulk orders?

Sample units are commonly offered at nominal cost, often credited toward future production orders. Pricing varies based on part complexity, ranging from $0.10 for simple plastic prints to $30+ for precision metal components.

What file formats do suppliers accept for prototyping?

Standard accepted formats include STEP, IGES, STL, DWG, and PDF drawings. Suppliers may also require bill of materials (BOM), assembly instructions, or tolerance specifications for complex assemblies.