Prototype Mfg

Top sponsor listing

Top sponsor listing

CN

CN

1/25

1/25

1/17

1/17

1/25

1/25

1/8

1/8

1/9

1/9

1/16

1/16

CN

CN

1/20

1/20

1/12

1/12

1/30

1/30

1/21

1/21

1/22

1/22

HK

HK

1/17

1/17

About prototype mfg

Where to Find Prototype Manufacturing Suppliers?

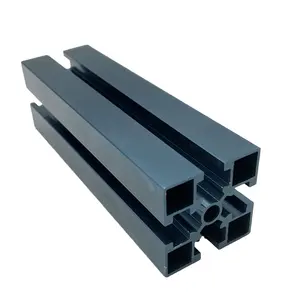

China remains a global hub for prototype manufacturing, with key industrial clusters in Shandong, Guangdong, and Zhejiang provinces offering specialized capabilities in rapid prototyping and low-volume production. Qingdao (Shandong) and Dongguan (Guangdong) host precision engineering firms equipped with multi-axis CNC machining, sheet metal fabrication, and plastic injection molding lines, enabling fast turnaround for functional prototypes. Wenzhou specializes in hardware-based prototypes using stainless steel and aluminum alloys, while Shenzhen’s ecosystem supports integrated electronics and mechanical prototyping through advanced 5-axis milling and rapid tooling.

These regions benefit from vertically integrated supply chains—local access to raw materials, surface treatment services, and metrology labs reduces lead times by 20–35% compared to offshore alternatives. Suppliers typically operate facilities ranging from 1,000 to 10,000+ m², supporting scalable output with average monthly capacities exceeding 50,000 units across metal and plastic components. Buyers gain flexibility in material selection—including ABS, POM, PC, aluminum 6061/7075, and stainless steel 304/316—and access to secondary operations such as anodizing, knurling, laser engraving, and custom packaging.

How to Choose Prototype Manufacturing Suppliers?

Effective supplier selection requires rigorous evaluation of technical capability, responsiveness, and quality control systems:

Technical & Process Compliance

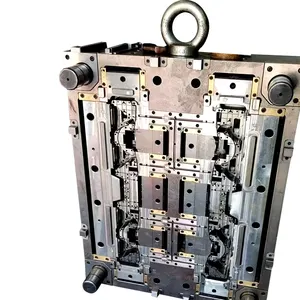

Verify the use of ISO 9001-aligned quality management practices. For regulated industries (medical, aerospace, automotive), confirm adherence to AS9100, IATF 16949, or ISO 13485 standards where applicable. Demand evidence of process validation, including first-article inspection reports (FAIR), coordinate measuring machine (CMM) data, and GD&T-compliant documentation.

Production Infrastructure Assessment

Evaluate core capabilities through these indicators:

- Availability of 3-, 4-, and 5-axis CNC machines with ±0.005 mm tolerance

- In-house capabilities in casting, forging, sheet metal stamping, and plastic prototyping (SLA/SLS/CNC)

- Dedicated R&D or engineering teams supporting design-for-manufacturability (DFM) feedback

Cross-reference facility size and equipment lists with on-time delivery performance (target ≥95%) and response time (ideally ≤7 hours).

Transaction & Quality Safeguards

Prioritize suppliers offering sample validation before mass production. Utilize secure payment mechanisms tied to milestone deliveries. Confirm post-production services such as batch traceability, packaging customization, and logistics coordination. Reorder rate (indicative of customer retention) above 35% is a strong proxy for service reliability.

What Are the Best Prototype Manufacturing Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order Quantity |

|---|---|---|---|---|---|---|---|

| Qingdao Dmetal International Trade Co., Ltd. | Casting, Sheet Metal Fabrication, Machining, Aluminum Profiles, Plastic & Forging Services | Color, material, size, logo, packaging, label, graphic | 100% | ≤7h | 37% | US $1,800,000+ | 1–10 pieces |

| Wenzhou Jiaheng Hardware Manufacturing Co., Ltd. | Precision CNC Machining, OEM Custom Parts | Chamfering, color, material, size, drawings, anodizing, logo, packaging, label, graphic, knurling, proofing | 100% | ≤3h | 100% | US $1,000+ | 1 piece |

| Yokan Precision Technology (Dongguan) Co., Ltd. | CNC Rapid Prototyping, High-Precision Aluminum & Semiconductor Components | Color, material, size, logo, packaging, label, graphic | 100% | ≤14h | - | - | 1 piece |

| SkyReach Intelligent MFG Limited | CNC Milling/Turning, Plastic & Metal Fabricated Parts | Color, material, size, logo, packaging, label, graphic | 87% | ≤3h | 15% | US $30,000+ | 1 piece |

| Shenzhen Jianfeng Precision Hardware Co., Ltd. | Rapid CNC Prototyping, Precision Turning/Milling | Color, material, size, logo, packaging, label, graphic | 100% | ≤1h | 47% | US $120,000+ | 1–10 pieces |

Performance Analysis

Wenzhou Jiaheng stands out with a 100% reorder rate and sub-3-hour response time, indicating high client satisfaction and operational agility. Shenzhen Jianfeng combines rapid responsiveness (≤1h) with strong repeat business (47% reorder rate) and transparent revenue reporting, suggesting stable production throughput. Qingdao Dmetal leads in reported online revenue (>$1.8M), reflecting extensive order volume across diverse prototype categories. Yokan Precision offers niche expertise in semiconductor-grade aluminum components but lacks reorder and revenue transparency. SkyReach, while technically capable, shows lower on-time delivery (87%) and reorder rates (15%), signaling potential scalability or consistency concerns. Buyers seeking high-reliability partners should prioritize suppliers with 100% on-time delivery and documented customization workflows.

FAQs

How to verify prototype manufacturing supplier reliability?

Request documented quality control procedures, including incoming material inspection, in-process checks, and final product verification. Validate certifications through issuing bodies. Assess responsiveness consistency and demand sample parts to evaluate dimensional accuracy and surface finish against specifications.

What is the typical lead time for prototype production?

Standard CNC prototypes take 5–10 days from design approval. Complex assemblies or those requiring tooling (e.g., injection molds) may require 15–25 days. Add 3–7 days for international air shipping depending on destination.

Do suppliers support small MOQs and one-off prototypes?

Yes, all listed suppliers offer minimum order quantities of 1 piece, making them suitable for R&D, testing, and pilot runs. Unit pricing decreases with volume, especially beyond 10–50 units.

Can prototype suppliers handle full product lifecycle support?

Top-tier suppliers provide DFM analysis, iterative prototyping, batch production, and after-sales adjustments. Confirm availability of engineering collaboration and revision tracking for long-term development projects.

What materials are commonly used in rapid prototyping?

Metals: Aluminum 6061/7075, stainless steel 304/316, brass, titanium.

Plastics: ABS, PC, POM (Delrin), PA (Nylon), PMMA (acrylic).

Selection depends on mechanical requirements, environmental exposure, and end-use application.