Prototype Smt Assembly

Top sponsor listing

Top sponsor listing

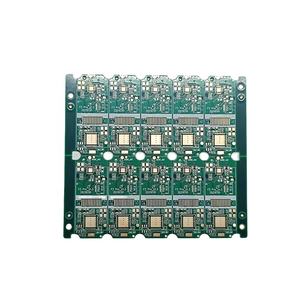

About prototype smt assembly

Where to Find Prototype SMT Assembly Suppliers?

China remains the global epicenter for prototype SMT assembly services, with Shenzhen and Dongguan in Guangdong Province forming high-density industrial hubs for electronics manufacturing. These regions host vertically integrated supply chains encompassing PCB fabrication, component sourcing, automated assembly, and testing—enabling rapid turnaround for low- to mid-volume production runs. Shenzhen alone accounts for over 70% of China’s PCBA service providers, supported by mature logistics networks that facilitate international shipping within 3–5 business days via express carriers.

The ecosystem thrives on specialization and scalability: suppliers operate fully automated SMT lines capable of placing components as small as 01005 packages with ±25μm accuracy, while maintaining flexibility for one-off prototypes. Lead times average 5–7 days for bare PCB assembly and 8–12 days for turnkey solutions including BOM sourcing. Cost efficiency is further enhanced by localized access to electronic components, FR-4 substrates, solder pastes, and stencils, reducing material procurement cycles by up to 60% compared to non-specialized regions.

How to Choose Prototype SMT Assembly Suppliers?

Procurement decisions should be guided by technical capability, operational reliability, and quality assurance protocols:

Technical Compliance & Quality Standards

Verify adherence to IPC-A-610 Class 2 or Class 3 standards for electronic assemblies. Look for evidence of automated optical inspection (AOI), in-circuit testing (ICT), and X-ray inspection for BGA packages. While ISO 9001 certification is not explicitly stated in available data, top-tier suppliers demonstrate process control through documented workflows, traceability systems, and reverse engineering capabilities.

Production Capacity & Responsiveness

Assess infrastructure maturity using key indicators:

- On-time delivery rate exceeding 95%

- Average response time under 3 hours

- Reorder rate above 30% indicating customer retention

- Support for mixed technology (SMT + DIP) assembly

Suppliers with dedicated prototyping lines can accommodate urgent orders within 72 hours. Cross-reference claimed capabilities with actual product listings—high-volume manufacturers often list standardized services, whereas specialized prototyping firms emphasize customization options such as color coding, label specifications, and design cloning.

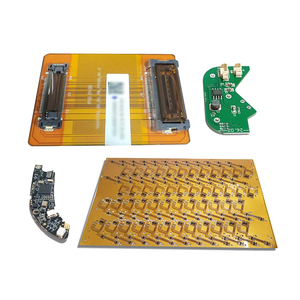

Customization & Turnkey Capability

Prioritize partners offering full turnkey solutions including component sourcing, BOM optimization, IC programming, and packaging. Advanced suppliers support gerber file validation, impedance control, rigid-flex board assembly, and substitutions for obsolete parts. Confirm ability to handle precision requirements like fine-pitch ICs, micro BGAs, and thermal management considerations during layout review.

What Are the Best Prototype SMT Assembly Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Features | Min. Order Quantity | Price Range (Sample) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Wonstron Technology Co., Ltd. | PCBA (892), Other ICs (345), Multilayer PCB (38) | US $260,000+ | 100% | 20% | ≤2h | BOM sourcing, reverse engineering, label specs, logo printing, Gerber processing | 1 pc | Not listed |

| Shenzhen Lihua Technology Co., Ltd. | PCBA (495), Other PCB & PCBA (186) | US $760,000+ | 93% | 36% | ≤6h | Component sourcing, design support, assembly, logo application | 1 pc | $0.09/unit |

| Tecoo Electronics Co., Ltd. | PCBA, Rigid-Flex, Multilayer PCB | US $460,000+ | 98% | 34% | ≤2h | AOI, reverse engineering, IC programming, high-precision placement, cloning | 10 pcs | $0.85–$10.40 |

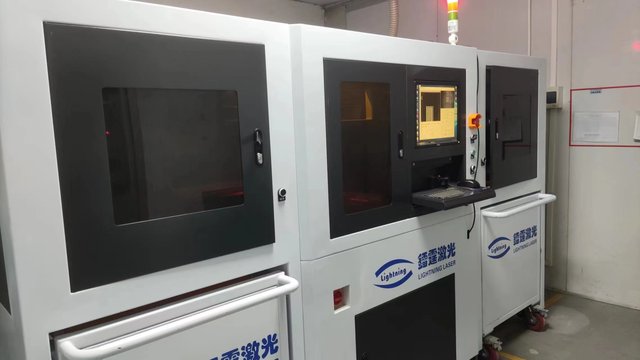

| Morel Equipments Co., Ltd. | SMT Pick-and-Place Machines, Assembly Lines | US $820,000+ | 100% | 50% | ≤1h | Machine customization, laser marking, fixture integration, automation upgrades | 1 set | $21,999/set |

| Dongguan Xinhao Technology Co., Ltd. | Custom PCBA, Multilayer PCB | US $1,000+ | 100% | 50% | ≤3h | Color options, material selection, logo, packaging labels, graphics | 1 pc | $0.80–$10/unit |

Performance Analysis

Shenzhen-based suppliers dominate in volume and service breadth, with Wonstron and Lihua offering scalable PCBA solutions backed by robust order fulfillment records. Tecoo Electronics stands out for advanced technical offerings, including automated optical inspection and reverse engineering, making it suitable for complex prototype iterations. Morel Equipments diverges from pure-service models by supplying SMT machinery itself, catering to buyers seeking in-house assembly line deployment. Dongguan Xinhao, despite lower reported revenue, achieves a 50% reorder rate—matching Morel's repeat business performance—indicating strong client satisfaction for low-MOQ prototyping needs.

Top performers combine sub-3-hour response times with 100% on-time delivery, critical for agile development cycles. Buyers requiring fast-turn prototypes should prioritize suppliers supporting single-piece orders and digital design validation. For compliance-sensitive applications, confirm RoHS and lead-free processing capabilities directly with engineering teams prior to release.

FAQs

How to verify prototype SMT assembly supplier reliability?

Evaluate on-time delivery history, reorder rate, and response time as proxies for operational discipline. Request sample boards to assess solder joint quality, alignment accuracy, and labeling consistency. Validate component sourcing policies—especially for restricted or long-lead items—and confirm traceability documentation per lot.

What is the typical lead time for prototype SMT assembly?

Standard turnaround ranges from 5 to 7 days for kitted assemblies and 8 to 12 days for turnkey orders involving component procurement. Expedited 72-hour services are available from select suppliers for simple designs with complete BOMs and Gerber files.

Do suppliers support single-unit prototype orders?

Yes, multiple suppliers—including Shenzhen Lihua and Dongguan Xinhao—accept minimum orders of 1 piece, making them ideal for initial functional testing and proof-of-concept builds.

Can suppliers source components globally?

Top-tier providers offer global BOM fulfillment, including authorized distribution channels and alternative part recommendations for obsolete or restricted components. Confirm whether counterfeit avoidance policies and original manufacturer sourcing are enforced.

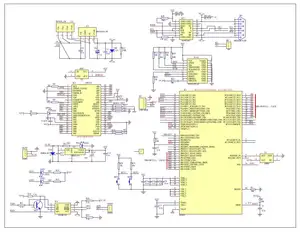

How are design files handled during the assembly process?

Suppliers typically accept Gerber files, BOM spreadsheets, pick-and-place data, and netlists. Leading firms conduct pre-assembly DFM checks and provide feedback on footprint mismatches, solder mask clearances, and fiducial placement. Ensure NDA coverage is in place before file submission.