Push Back Racking System

CN

CN

CN

CN

CN

CN

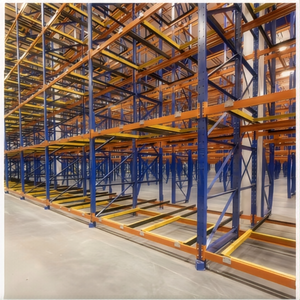

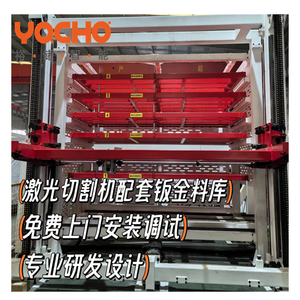

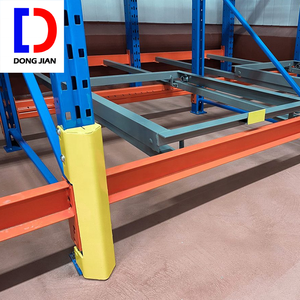

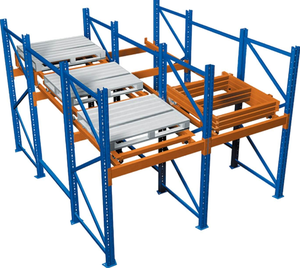

About push back racking system

Where to Find Push Back Racking System Suppliers?

China remains the global epicenter for push back racking system manufacturing, with key production clusters in Anhui, Guangdong, Jiangsu, and Guangxi provinces. These regions host vertically integrated facilities specializing in warehouse storage solutions, leveraging localized steel supply chains and automated fabrication lines to achieve 20–30% cost efficiency over Western counterparts. Proximity to major ports such as Qingdao, Nanning, and Guangzhou enables streamlined export logistics, reducing transit times for international buyers.

Suppliers in these hubs operate high-capacity production environments equipped with CNC roll-forming, robotic welding, and powder-coating systems, ensuring dimensional accuracy and corrosion resistance. The concentration of component manufacturers—ranging from load-bearing rails to roller carts—within 50km radii supports rapid prototyping and bulk order fulfillment. Average lead times range from 15 to 30 days for standard configurations, with scalability for containerized shipments serving global distribution centers, cold storage facilities, and e-commerce fulfillment warehouses.

How to Choose Push Back Racking System Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Quality Management Standards

Verify adherence to ISO 9001-certified quality control processes. Structural integrity is paramount; request material test reports (MTRs) confirming use of Q235 or Q345-grade steel with yield strengths exceeding 235 MPa. For operations in humid or outdoor environments, confirm anti-rust treatments such as electrophoretic coating or hot-dip galvanization.

Production and Engineering Capacity

Assess infrastructure maturity through objective benchmarks:

- Minimum factory area of 5,000m² to support continuous production

- In-house design teams capable of generating layout drawings and load capacity calculations

- CNC-controlled forming lines and automated welding stations

Cross-reference on-time delivery performance (target ≥98%) with customization capability indicators, including frame height adjustment, layer configuration, and pallet interface specifications.

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services to mitigate risk. Prioritize suppliers with documented reorder rates above 25%, indicating customer satisfaction and product reliability. Request physical or digital samples to validate build quality, cart mobility, and structural alignment before full-scale orders.

What Are the Best Push Back Racking System Suppliers?

| Company Name | Location | Online Revenue | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Terms |

|---|---|---|---|---|---|---|---|---|

| Anhui Rongda Intelligent Equipment Manufacturing Co., Ltd. | Anhui, CN | US $130,000+ | Stacking Racks & Shelves (164), Cargo & Storage Equipment (80) | 100% | ≤1h | 100% | Not specified | $0.90/kg; 1,000 kg |

| Guangzhou Heda Warehouse Equipment Co., Ltd. | Guangdong, CN | US $40,000+ | Multipurpose industrial racking systems | 50% | ≤4h | 28% | Color, material, size, logo, packaging, graphic | $48–88/set; 10 sets |

| Nanjing Peter Logistics Equipment Co., Ltd. | Jiangsu, CN | US $60,000+ | Heavy-duty, anti-rust, high-security push-back racks | 100% | ≤3h | 20% | Frame design, layers, capacity, material, color, labeling | $0.84–1.20/kg; 20 kg |

| Guangxi Nanning Jianzhian Integrated Housing Co., Ltd. | Guangxi, CN | US $960,000+ | Steel shelving, boltless racks, stacking systems | 98% | ≤1h | 30% | Size, color, weight capacity, mezzanine integration, design | $14.90–19/unit; 1 unit |

| Qingdao Junhan Commercial Equipment Co., Ltd. | Shandong, CN | US $20,000+ | Supermarket shelves, industrial stacking racks | 100% | ≤2h | <15% | Adjustable levels, load capacity (100–500kg) | $25–29/set; 10 sets |

Performance Analysis

Anhui Rongda stands out with a perfect 100% on-time delivery and reorder rate, suggesting strong process consistency and client retention. Guangxi Nanning Jianzhian reports the highest online revenue (US $960,000+), reflecting scalable operations and market reach, supported by a 98% fulfillment rate and sub-1-hour response time. Nanjing Peter and Anhui Rongda offer ultra-low MOQs starting at 20 kg and 1,000 kg respectively, ideal for buyers testing new configurations or fulfilling partial warehouse upgrades.

Guangzhou Heda provides extensive customization but lags in delivery reliability (50%), warranting closer monitoring during order execution. Qingdao Junhan, while responsive and punctual, has a low reorder rate (<15%), potentially indicating niche positioning or limited post-sale engagement. Buyers prioritizing flexibility should evaluate per-unit pricing models like those from Guangxi Nanning, which allow procurement from a single unit, versus weight-based or set-based structures requiring larger initial commitments.

FAQs

How to verify push back racking system supplier reliability?

Validate certifications, production scale, and transaction history. Request facility videos demonstrating CNC processing and load-testing procedures. Analyze verifiable performance metrics such as on-time delivery rate, response speed, and repeat order frequency. Third-party inspection services can audit both factory operations and finished goods prior to shipment.

What is the typical lead time for push back racking systems?

Standard orders are typically fulfilled within 15–30 days after confirmation. Custom designs involving non-standard dimensions or specialized coatings may extend lead times to 45 days. Expedited production is available from suppliers with in-house engineering and modular component inventories.

Can suppliers customize push back racking configurations?

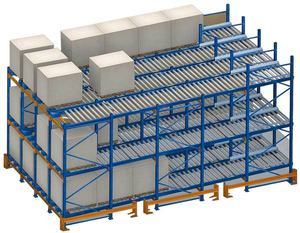

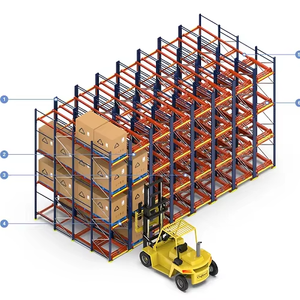

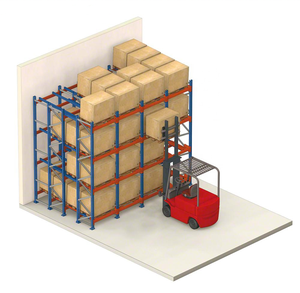

Yes, most leading suppliers offer customization in rack height, depth, number of storage levels (typically 2–5 deep), load capacity (ranging from 1,000 kg to 3,000 kg per pallet position), and surface finish. Design modifications for seismic zones or narrow-aisle applications require engineering validation and structural analysis documentation.

What are common MOQ requirements?

MOQs vary significantly: some suppliers require 1,000 kg minimums priced per kilogram, while others offer set-based pricing starting at 10 units or even single-unit sales. Lower MOQs enhance procurement agility but may incur higher per-unit costs. Negotiate tiered pricing based on volume brackets for optimal cost efficiency.

How are push back racking systems packaged and shipped internationally?

Racks are typically flat-packed with protective corner guards and bundled via steel straps for container shipping. FOB terms are common; suppliers in coastal provinces offer direct loading into 20' or 40' HQ containers. Confirm compatibility with your inbound logistics and handling equipment, particularly for heavy-duty frames exceeding 2,000 kg per bay.